Creep-fatigue property testing system with controllable oxygen partial pressure

A fatigue performance test and oxygen partial pressure technology, which is applied in the field of creep fatigue performance test system, can solve the problems of no explosion-proof measures, inability to maintain pressure, and inability to control oxygen partial pressure, etc., to achieve high test accuracy, stable and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Below in conjunction with the drawings, preferred embodiments of the present invention are given and described in detail.

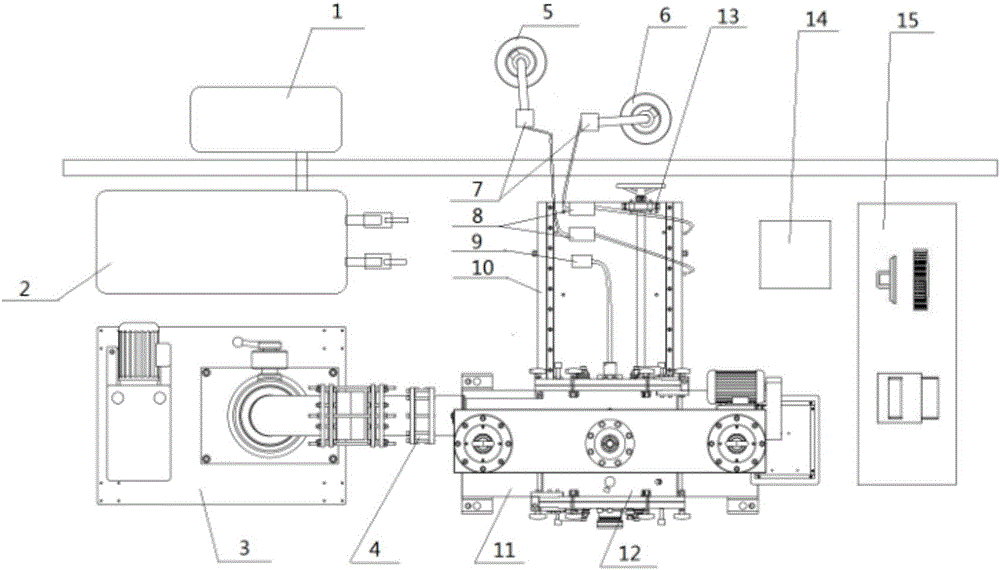

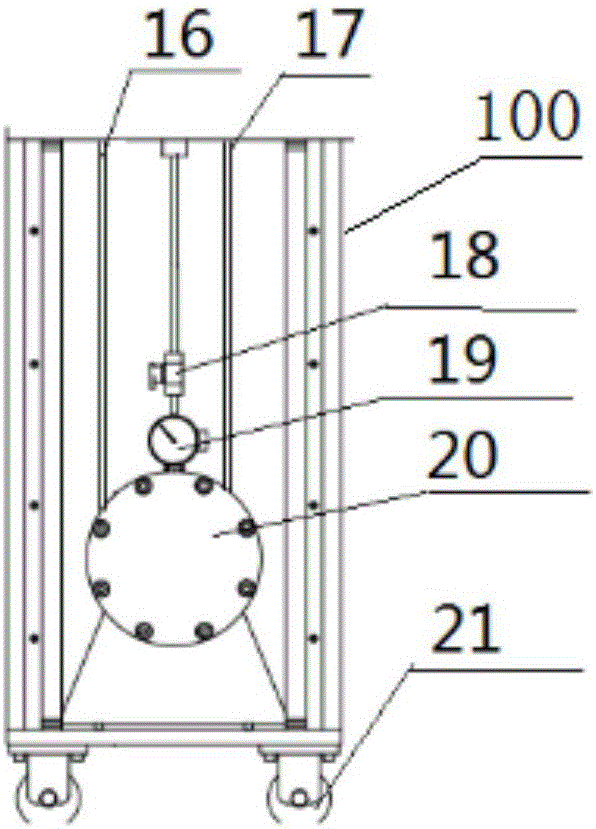

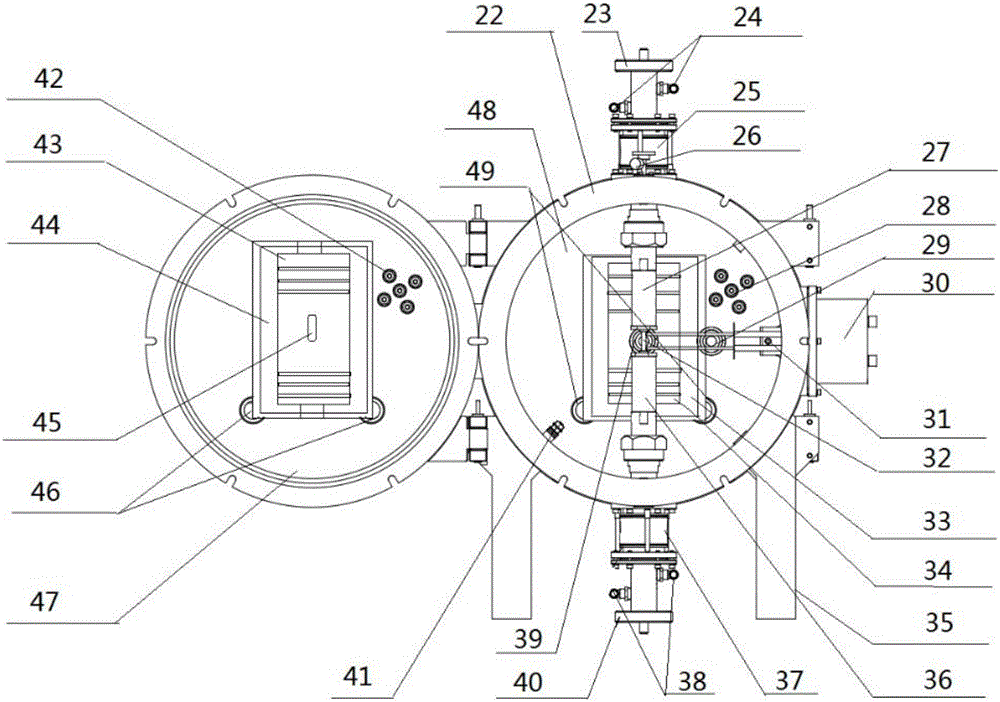

[0049] Such as Figure 1-4 As shown, the present invention is a creep fatigue performance test system with controllable oxygen partial pressure, which includes: a mixed gas inflation subsystem, a mechanical loading host 11, an inflatable high-temperature furnace 12, a deformation measurement extensometer 31, a cycle water cooling Subsystem and computer industrial control subsystem.

[0050] Specifically, the mixed gas filling subsystem includes: a high vacuum unit 3, an oxygen source 5, an argon source 6, and a premixed gas charging tank cabinet 10, wherein,

[0051] The high-vacuum unit 3 is connected to the gas-filled high-temperature furnace 12 through the high-vacuum butterfly valve 4 to pre-evacuate the air in the gas-filled high-temperature furnace 12;

[0052] Oxygen source 5 and argon gas source 6 are respectively connected to premixed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com