Gas sensor calibration device and calibration method thereof

A gas sensor and calibration device technology, applied in the direction of standard gas analyzers, measuring devices, and gas mixture analysis, can solve the problems of high labor intensity, low work efficiency, and low calibration accuracy, so as to improve calibration accuracy and use effect Good, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

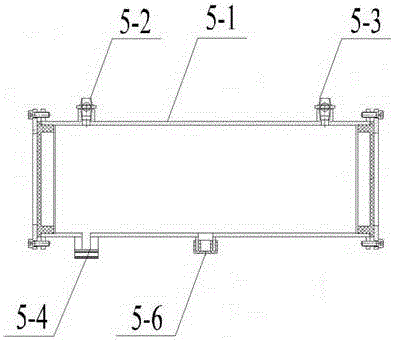

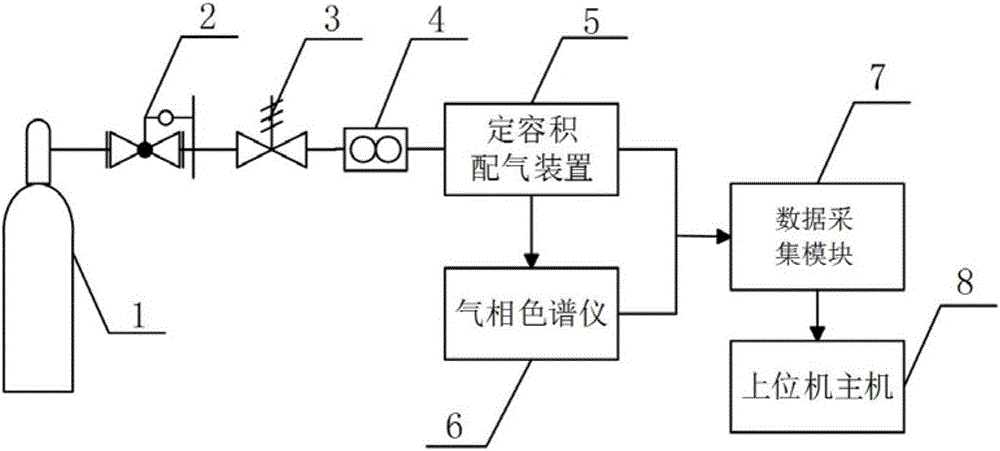

[0029] like figure 1 As shown, a gas sensor calibration device includes a gas cylinder 1 for storing detected gas, a pressure reducing valve 2, a constant volume gas distribution device 5, a gas chromatograph 6, a data acquisition module 7 and a host computer 8. Fixed volume air distribution device 5 such as figure 2 As shown, its main body is a metal cylindrical cavity 5-1 with a volume V, and both ends of the metal cylindrical cavity 5-1 are provided with metal end caps, which are fixed by bolts. A gas inlet 5-2 is arranged at one end of the metal cylindrical cavity 5-1, and a gas outlet 5-3 is arranged at the other end, and a ball valve is arranged at the gas inlet 5-2 and the gas outlet 5-3. A first sensor base 5-4 and a gas sampling port 5-6 are provided on the side surface of the metal cylindrical cavity 5-1, and the gas sampling port communicates with the inside of the metal cylindrical cavity 5-1.

[0030] The inlet of the pressure reducing valve 2 is connected to t...

Embodiment 2

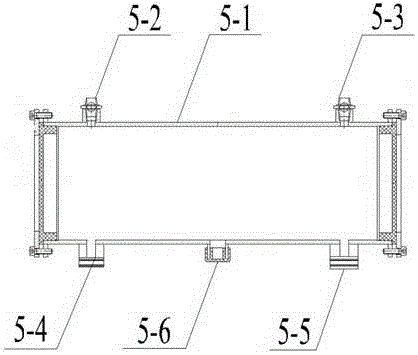

[0039] like image 3 As shown, a gas sensor calibration device includes a gas cylinder 1 for storing detected gas, a pressure reducing valve 2 , a fixed volume gas distribution device 5 , a data acquisition module 7 and a host computer 8 . Fixed volume air distribution device 5 such as Figure 4 As shown, its main body is a metal cylindrical cavity 5-1 with a volume V, and both ends of the metal cylindrical cavity 5-1 are provided with metal end caps, which are fixed by bolts. A gas inlet 5-2 is arranged at one end of the metal cylindrical cavity 5-1, and a gas outlet 5-3 is arranged at the other end, and a ball valve is arranged at the gas inlet 5-2 and the gas outlet 5-3. A first sensor base 5-4 and a second sensor base 5-5 are provided on the side surface of the metal cylindrical cavity 5-1.

[0040] The inlet of the pressure reducing valve 2 is connected to the gas outlet of the gas cylinder 1, and the outlet of the pressure reducing valve 2 is connected to the gas inlet...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap