Non-color shifting multilayer structure and protective coating on the same

A protective coating, multi-layer structure technology, used in inorganic pigment processing, wet preparation of dyed pigments, mirrors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

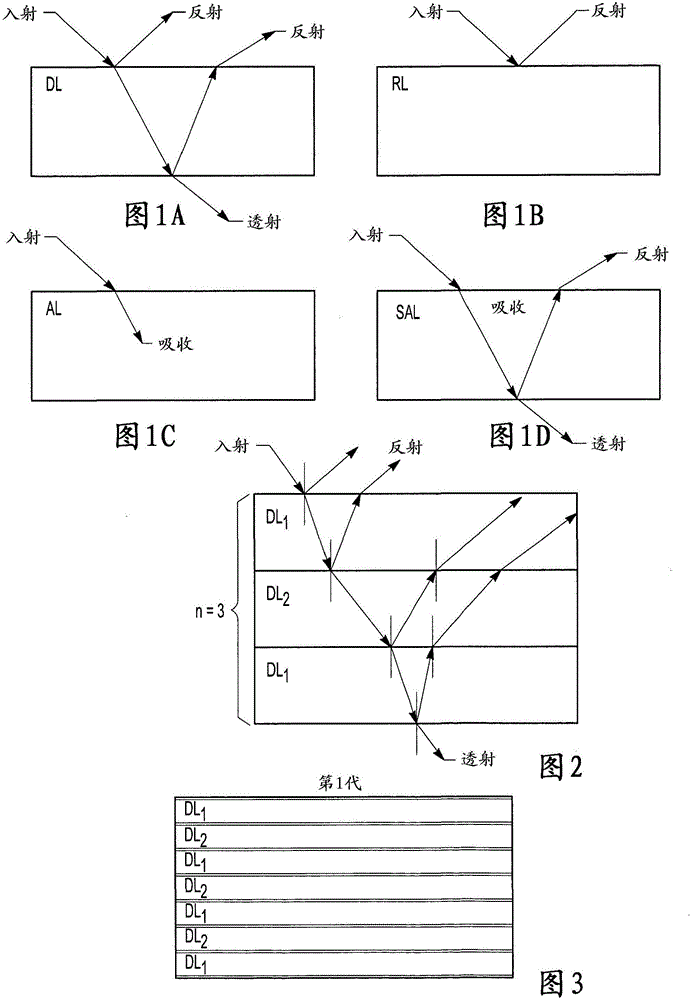

[0054] Provides an omnidirectional structural color. The omnidirectional structural color is in the form of a multilayer film (also referred to herein as a multilayer stack) that reflects a narrow band of frequencies within the visible spectrum when viewed from an angle between 0 and 45 degrees. electromagnetic radiation with little or no noticeable color shift. Multilayer films can be used as pigments in coating compositions, structurally continuous films, and the like.

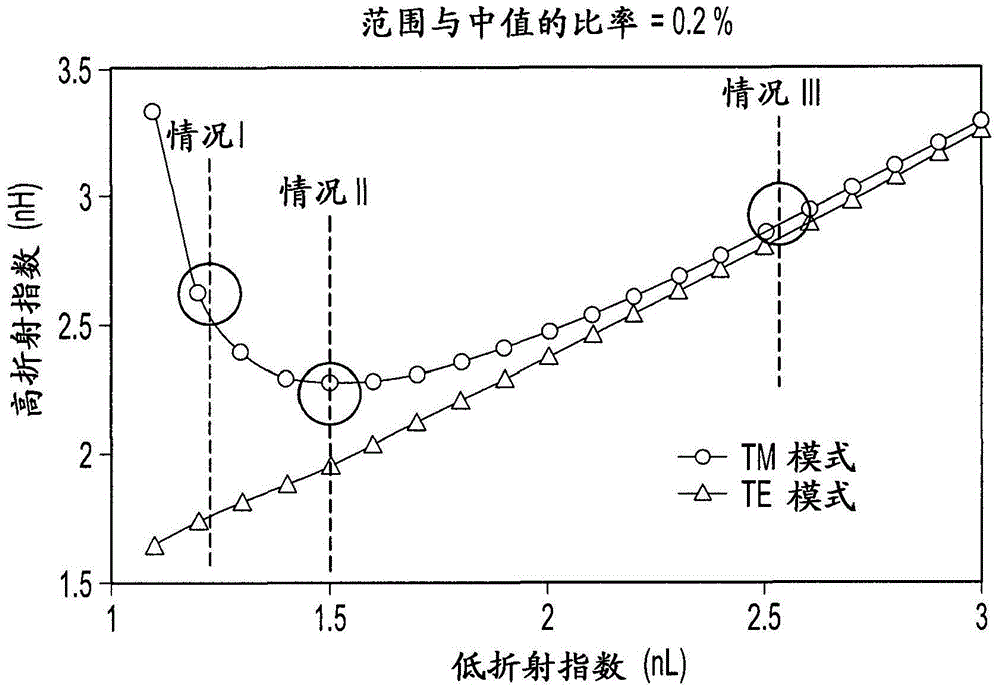

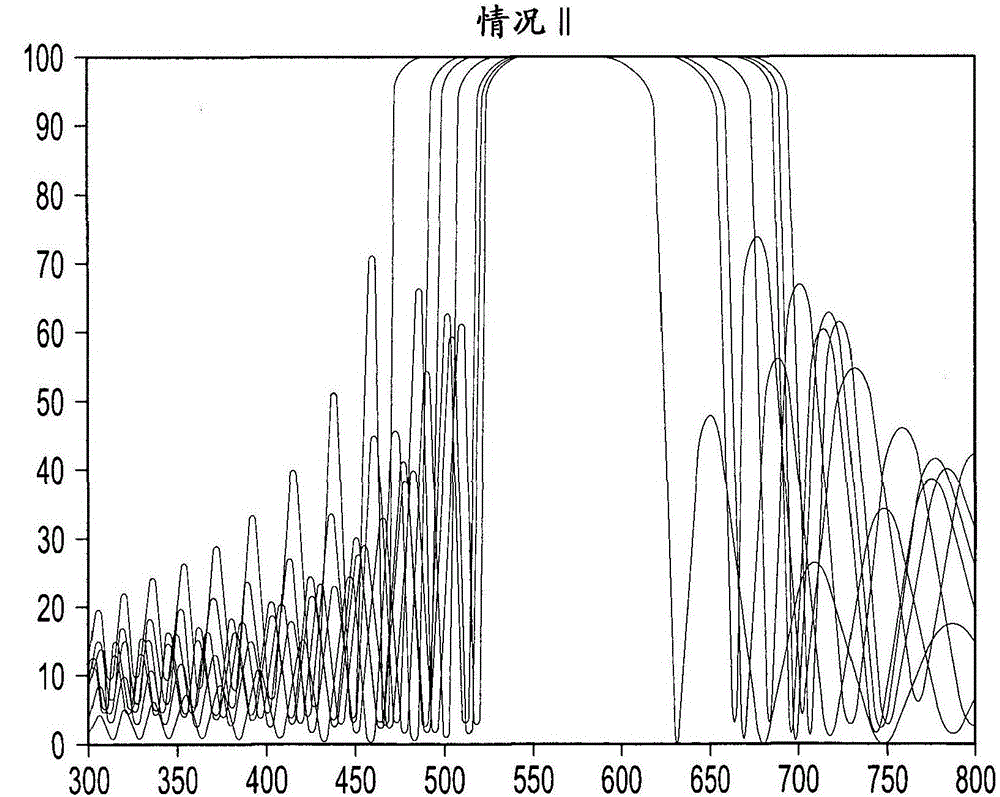

[0055] The multilayer film includes a multilayer stack having a first layer and a second layer extending across the first layer. In some cases, the multilayer stack reflects narrowband electromagnetic radiation having a FWHM of less than 300 nm, preferably less than 200 nm, and in some cases less than 150 nm. When the multilayer stack is exposed to broadband electromagnetic radiation (such as white light) and the multilayer stack is viewed from an angle between 0 and 45 degrees, the multilayer film also ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com