Health monitoring method for numerical control machine tool

A technology for CNC machine tools and health monitoring, applied in program control, computer control, general control systems, etc., can solve the problems of untimely and inaccurate judgment of the health status of CNC machine tools, and achieve the effect of convenient inspection and reasonable comparison.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

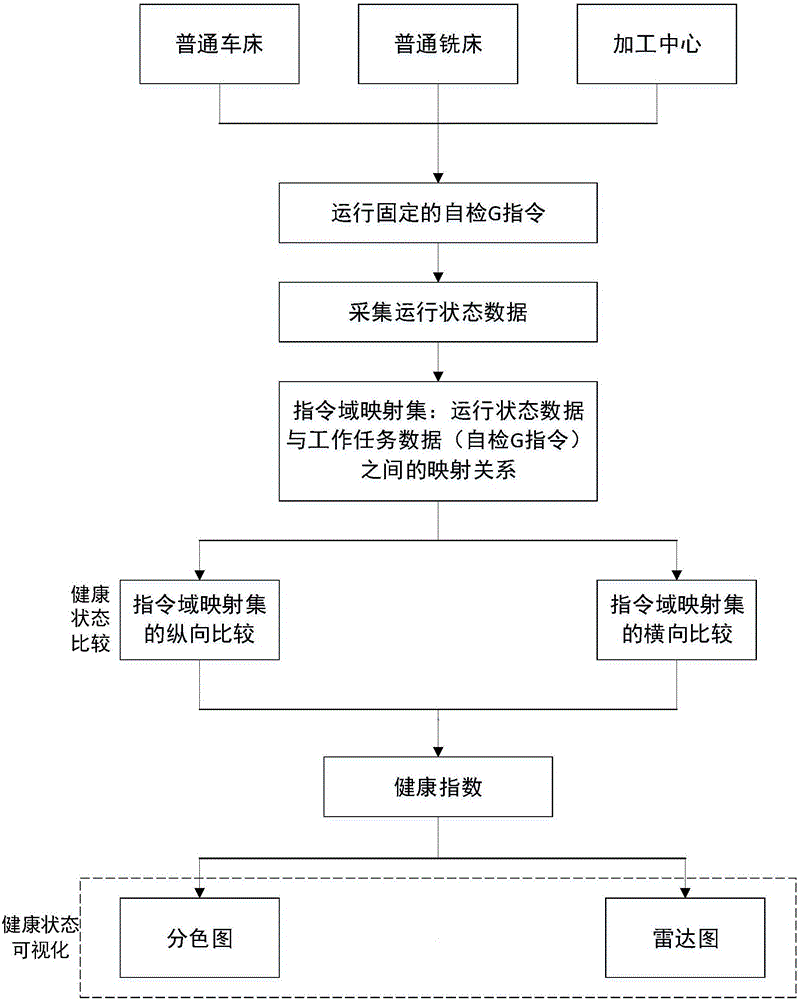

[0037] like figure 1 Shown, the health monitoring method of the numerically controlled machine tool among the present invention, comprises the following steps:

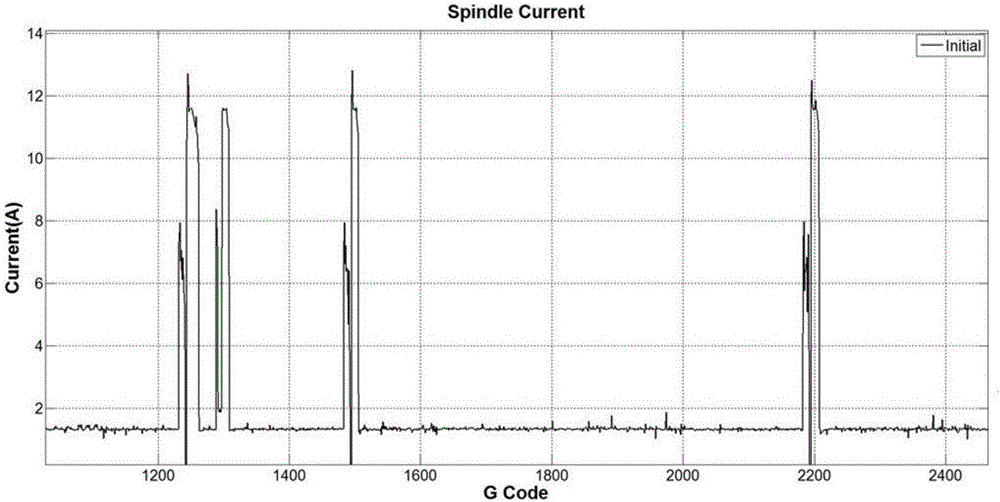

[0038] Step 1: Taking the CNC machine tool adopting a vertical machining center as an example, run a specific self-inspection G code (that is, a self-inspection G command) and collect operating status data.

[0039] For vertical machining centers, the content of the work task data, that is, the self-inspection G command, is shown in Table 1, Table 2, and Table 3 below:

[0040] Table 1 The single-axis operation parameters of the feed axis for the vertical machining center

[0041] project

Operating interval

running speed

Number of runs

X axis

-500-0

3000mm / min

2

Y axis

-100-290

3000mm / min

2

Z axis

-250-40

3000mm / min

2

[0042] Table 2 Operating parameters for the dual-axis circular motion of the vertical machining center

[0043] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com