Industrial robot application and control practical training platform

An industrial robot and training platform technology, applied in the field of teaching aids, can solve problems such as single function, lack of six-axis robot development, and reduce the fun of learning robots, so as to avoid damage, improve practical ability, and increase fun.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

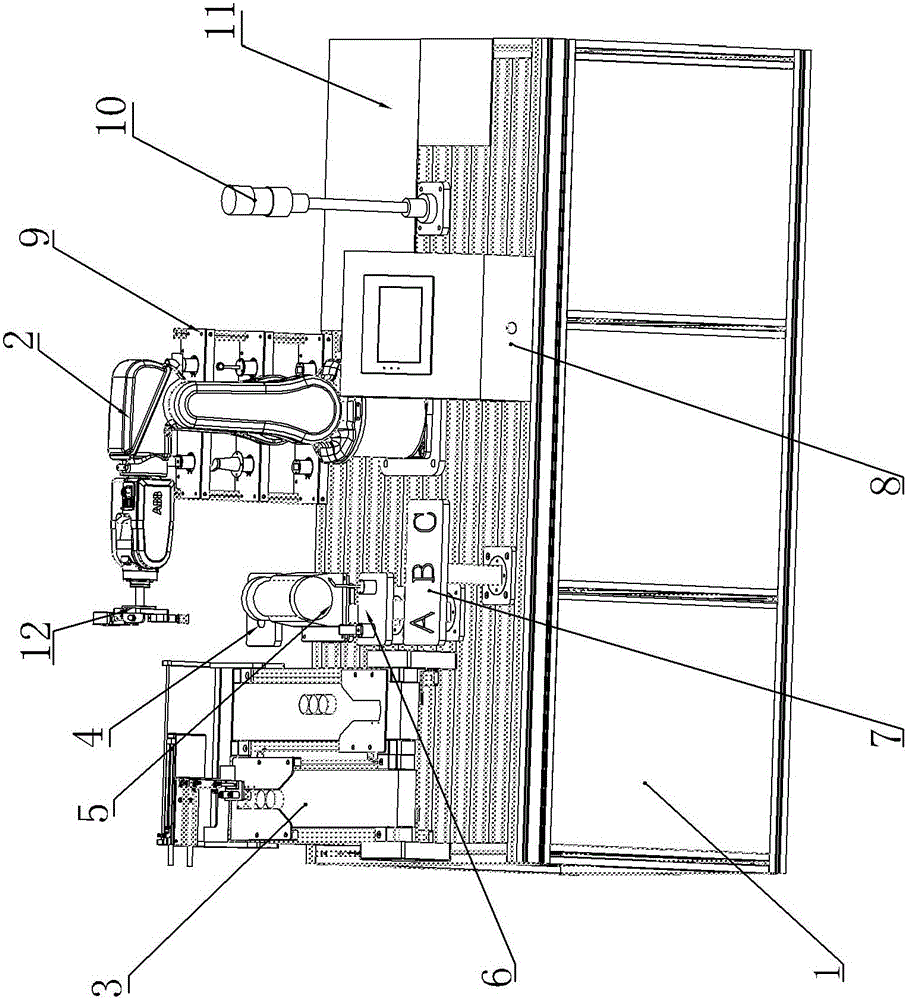

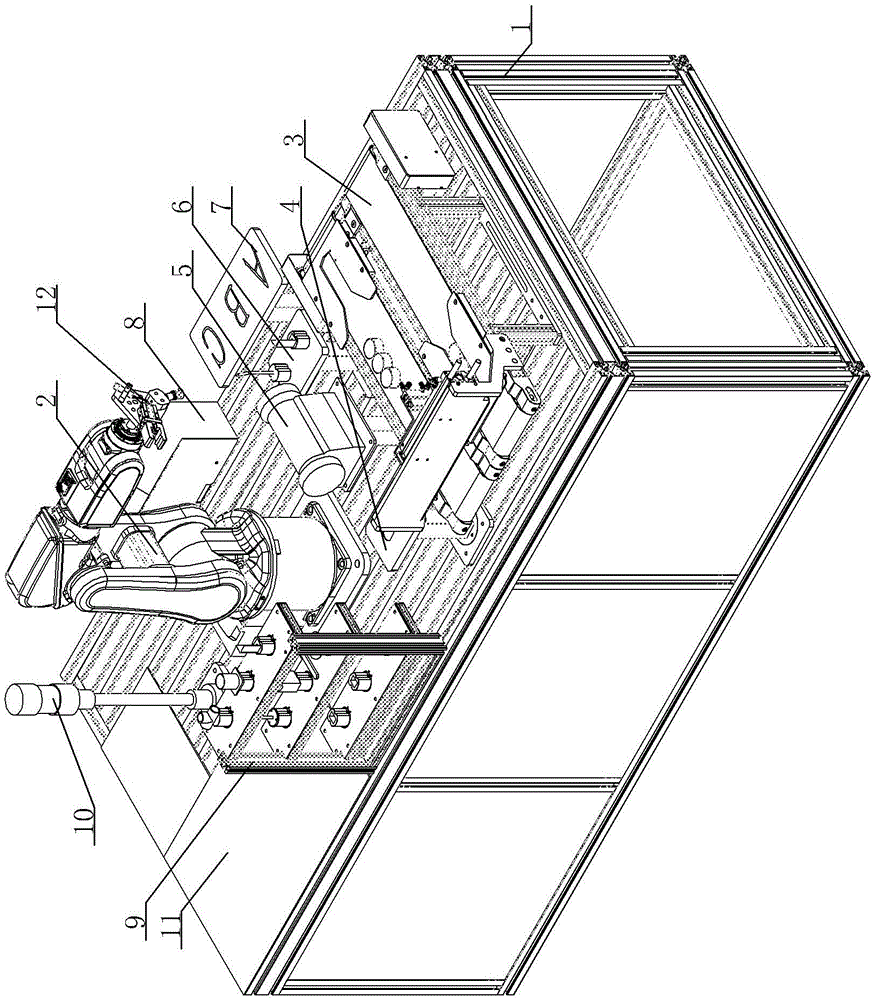

[0018] An industrial robot application and control training platform, see figure 1 , figure 2 : It includes a training platform main body 1, a robot body 2 is arranged at the center of the training platform main body 1, an electrical installation module 11 is built in the training platform main body 1, and a laser engraving demonstration module is also provided on the upper end surface of the training platform main body 1 , intelligent storage palletizing module, simulated welding module, simulated grinding module, robot handling module, touch screen box, and electrical installation module respectively connected to the robot body through PLC wiring 2, laser engraving demonstration module, intelligent storage palletizing module, simulated welding module, simulation The grinding module, the robot handling module, and the touch screen box 8 are used to control the working state between the robot body 2 and the corresponding modules.

[0019] The robot body 2 is specifically a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com