Centrifugal cleaning device and method for operating the centrifugal cleaning device

A cleaning equipment and matching technology, applied in cleaning methods and utensils, chemical instruments and methods, centrifuges, etc., can solve problems such as difficult realization and inflexibility of centrifugal cleaning equipment, and achieve short cycle time, simple operation process, and compact The effect of the design structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

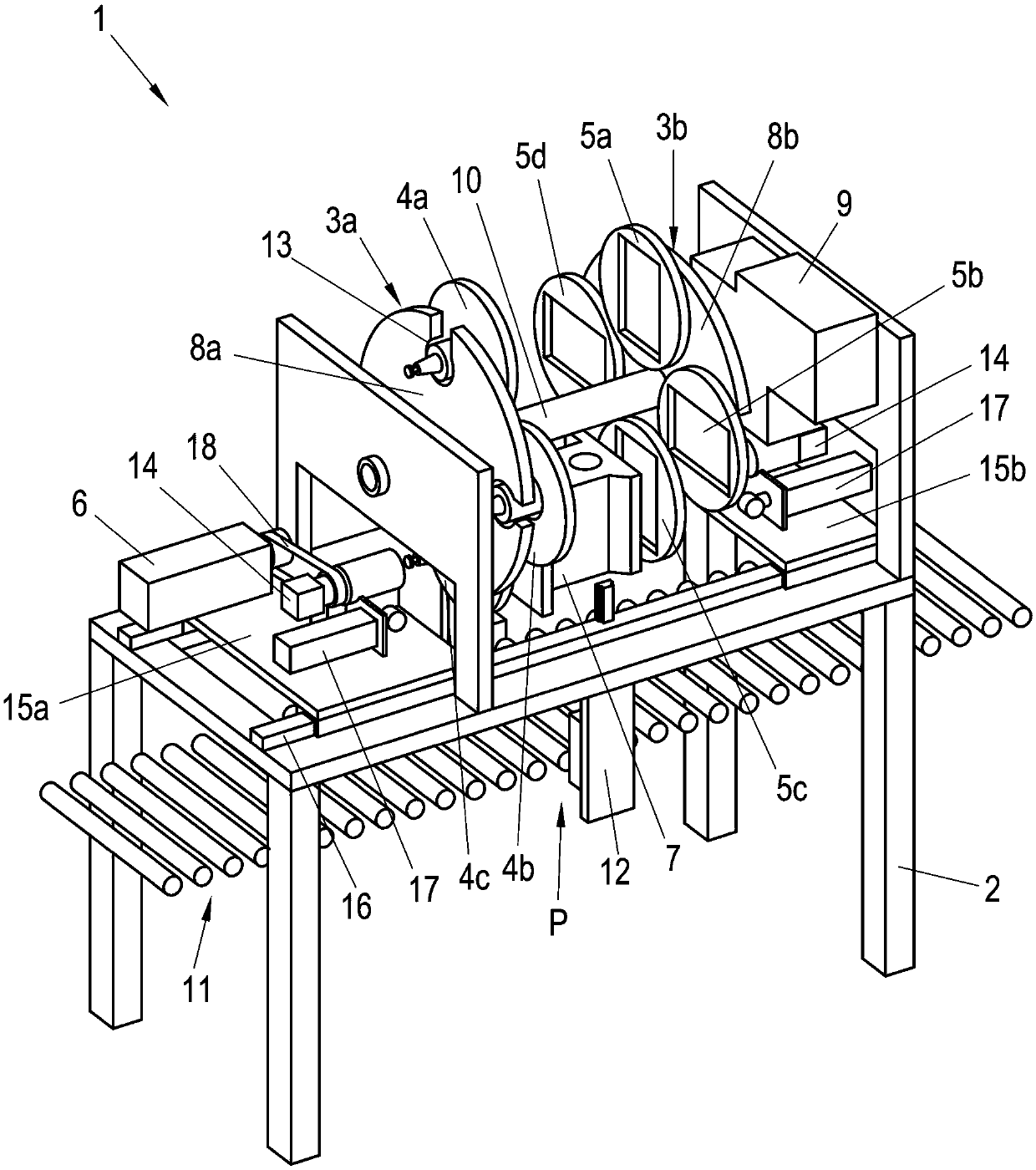

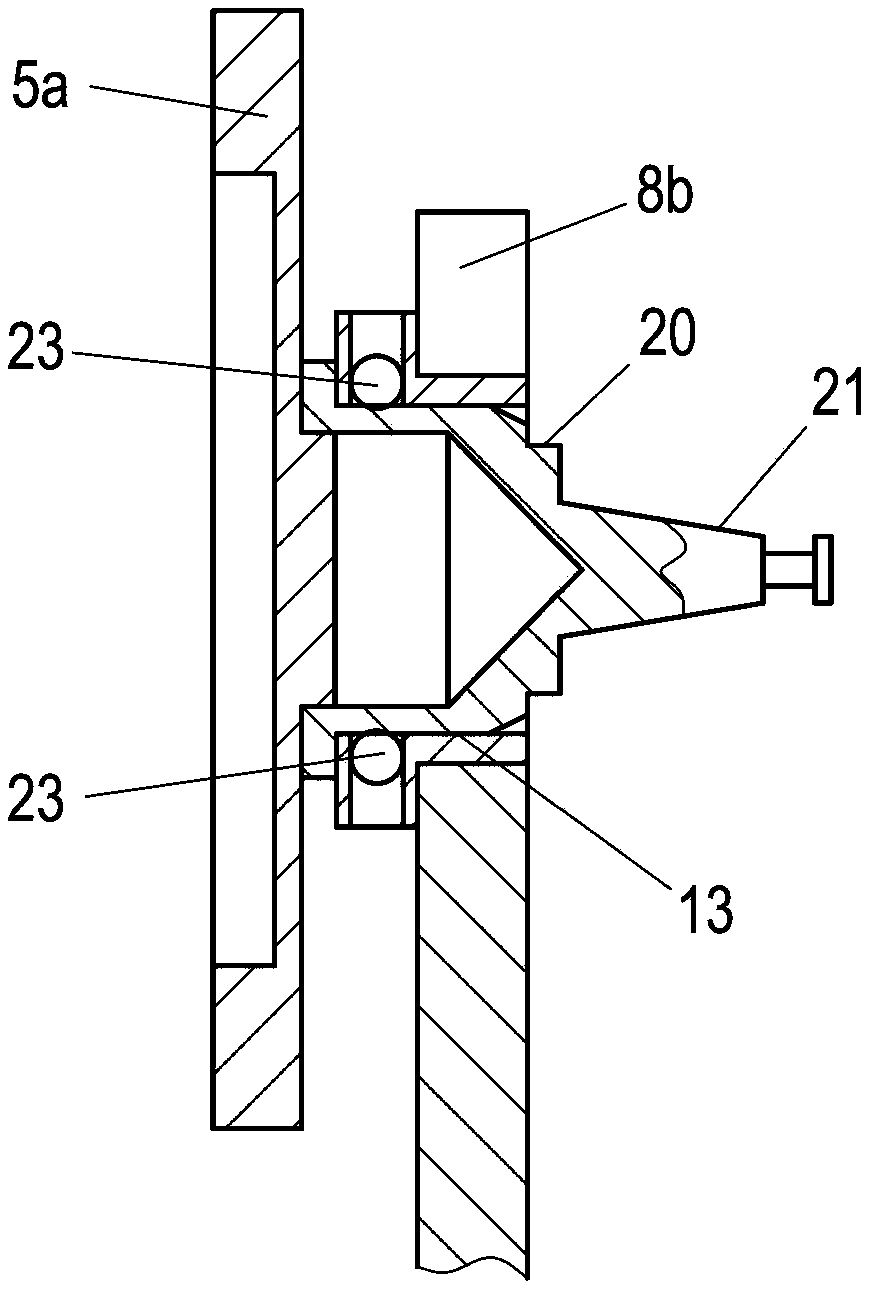

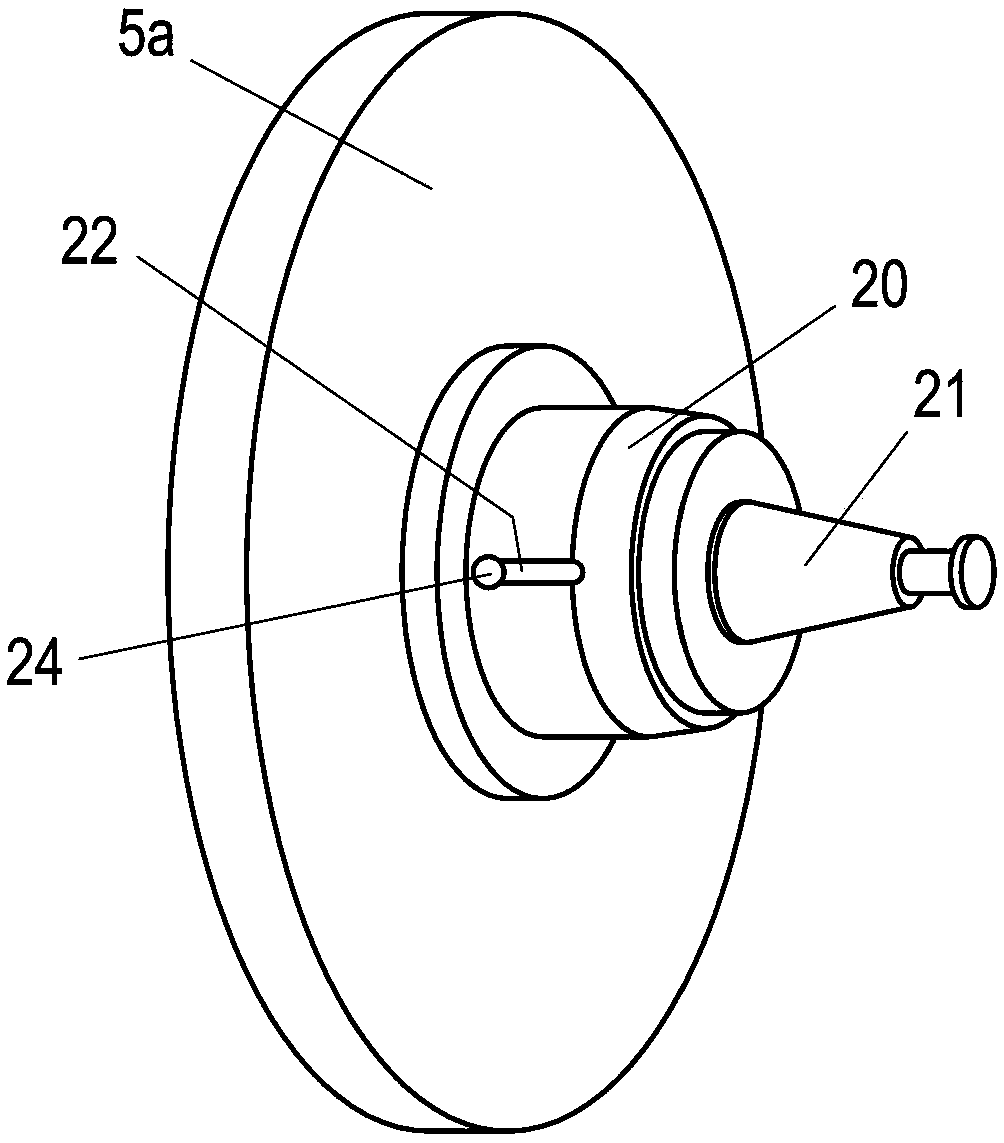

[0026] Below, refer to figure 1 . The centrifugal cleaning device 1 according to the invention is explained in more detail with the aid of a specific advantageous embodiment (in a particularly compact design). The centrifugal cleaning device 1 here comprises a stationary support structure 2 , on which are arranged opposing component receiver magazines 3 a , 3 b and a drive system 6 for the component receiver 4 . There are component receptacles 4a, 4b, 5a-5d held therein. Furthermore, the centrifugal cleaning device 1 comprises opposite clamping means 14 , by means of which the component holders 4 a , 4 b , 5 a - 5 d can be captured, clamped and held. In the exemplary embodiment shown, the component 7 is to be held between two opposing, matching component receptacles 4c, 5c, as will be explained in more detail below. Thus, in figure 1 There are also two component receptacle magazines 3a, 3b arranged axially spaced apart from each other. However, it goes without saying that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com