Cooling device for machine tool machining

A cooling device and machine tool technology, applied in the field of machine tool parts, can solve the problems of working environment pollution, affecting the health of workers, inability to isolate and settle dust and powder, and achieve the effect of good coverage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

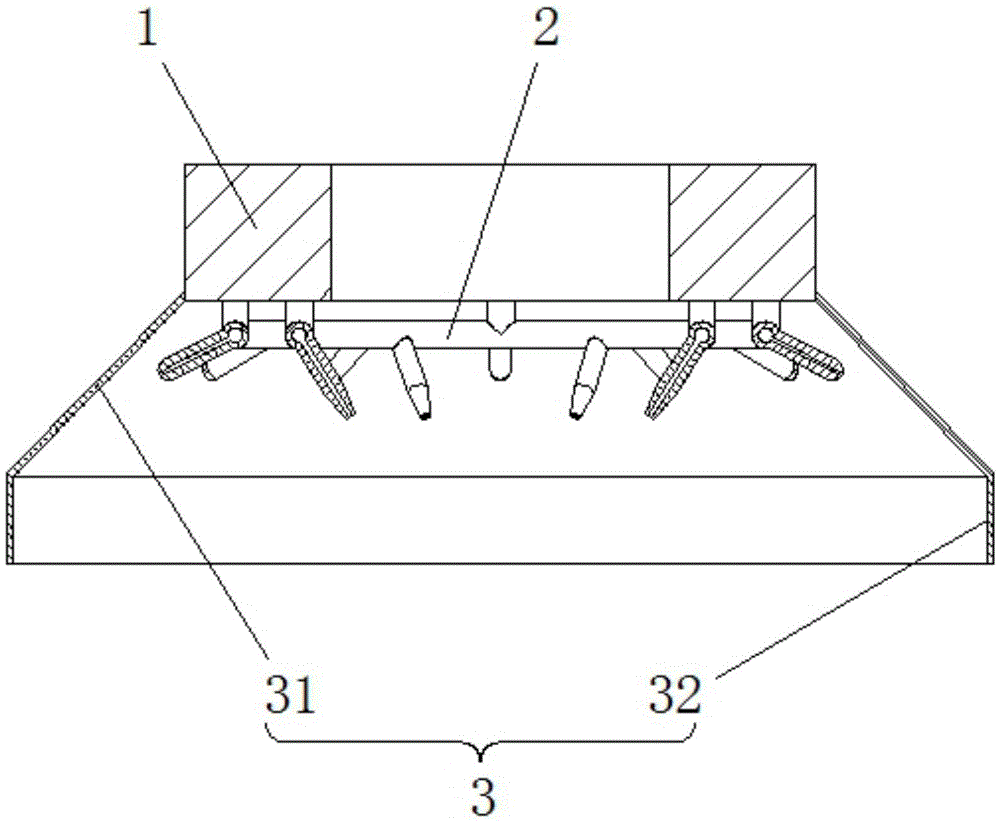

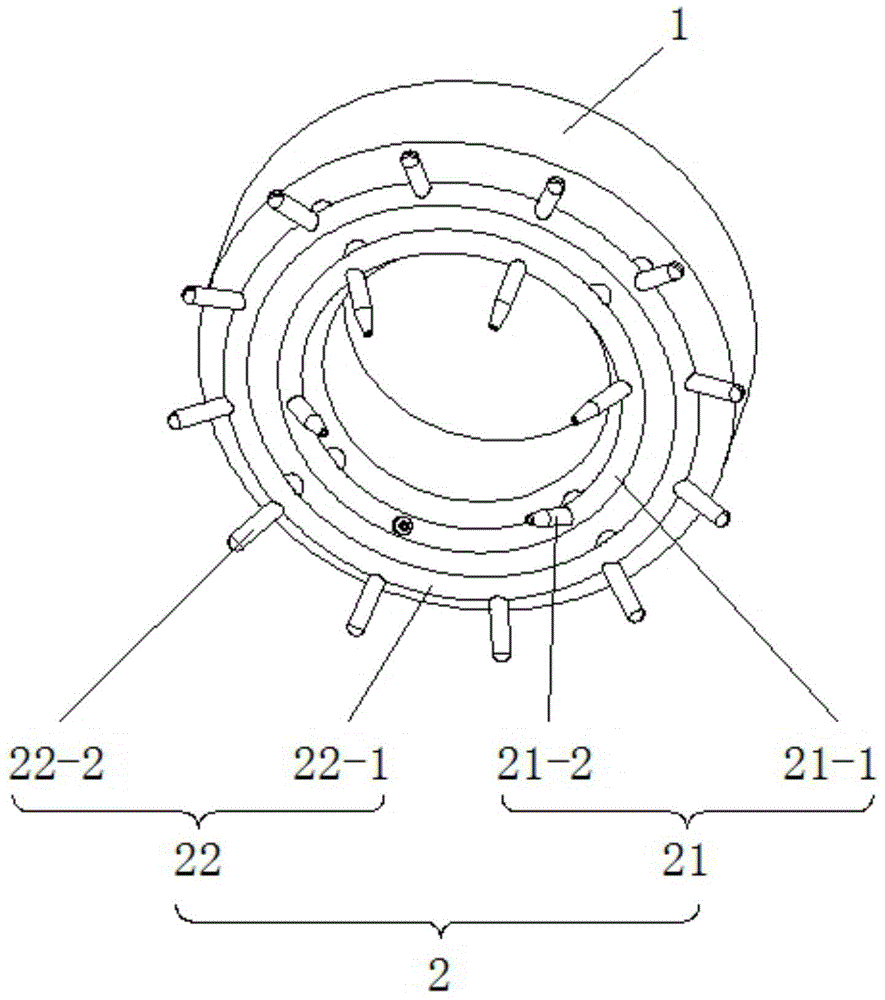

[0012] See figure 1 and figure 2 , the present invention has a mounting base 1, and a cooling nozzle group (2) is installed on the mounting base 1; it is characterized in that: the mounting base 1 is annular, and the center of the mounting base 1 is provided with a through hole for the main shaft to pass through; the cooling The nozzle group 2 includes a first nozzle group 21 and a second nozzle group 22; the first nozzle group 21 includes an annular first water inlet pipe 21-1 and a plurality of equidistantly arranged on the first water inlet pipe 21-1. The first nozzle 21-2 to adjust the spray direction; the second nozzle group 22 includes an annular second water inlet pipe 22-1 and a plurality of second nozzles 22-2 equidistantly arranged on the second water inlet pipe 22-1 ; The outer ring of the mounting seat 1 is provided with an annular blocking piece 3 , and the first nozzle group 21 and the second nozzle group 22 are arranged in the annular blocking piece 3 .

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com