Chemical mechanical grinding equipment and method

A chemical-mechanical and grinding method technology, applied in grinding/polishing equipment, metal processing equipment, grinding machines, etc., can solve the problems of reduced production output, reduced thickness uniformity of ground silicon wafers, and reduced silicon wafer thickness uniformity, etc. To achieve the effect of reducing production costs, reducing waste production, and improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

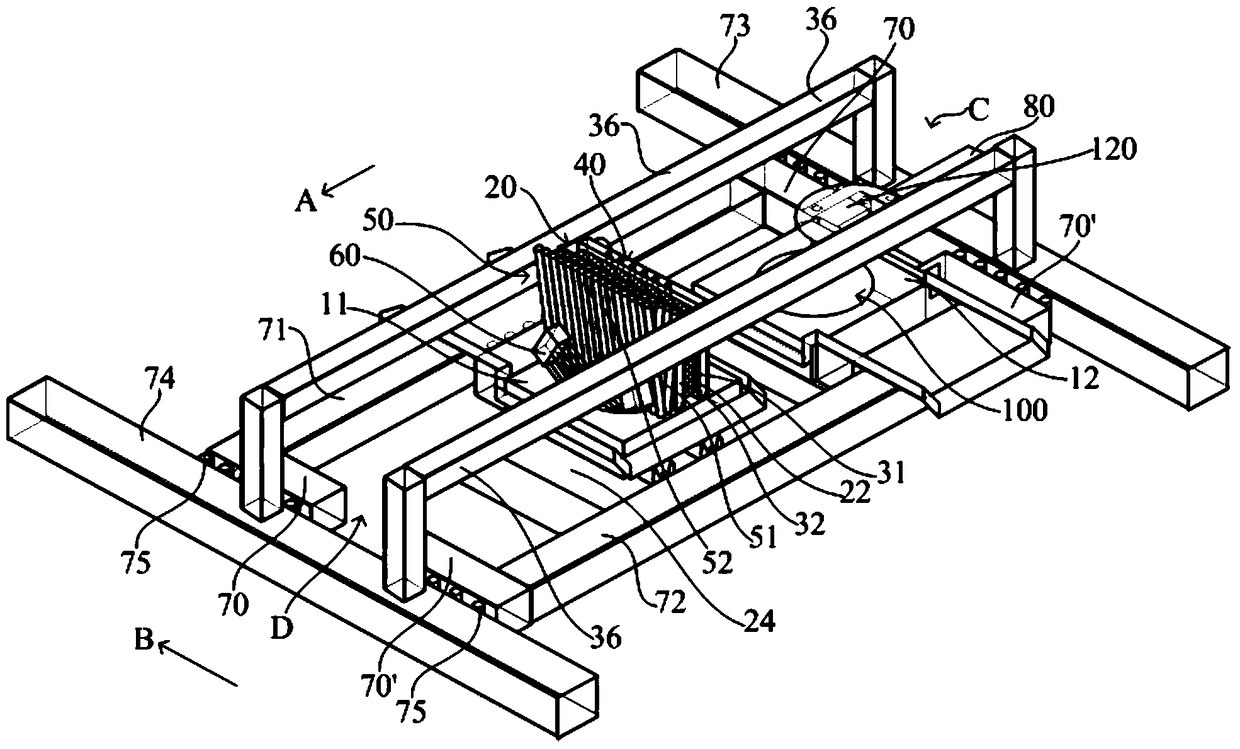

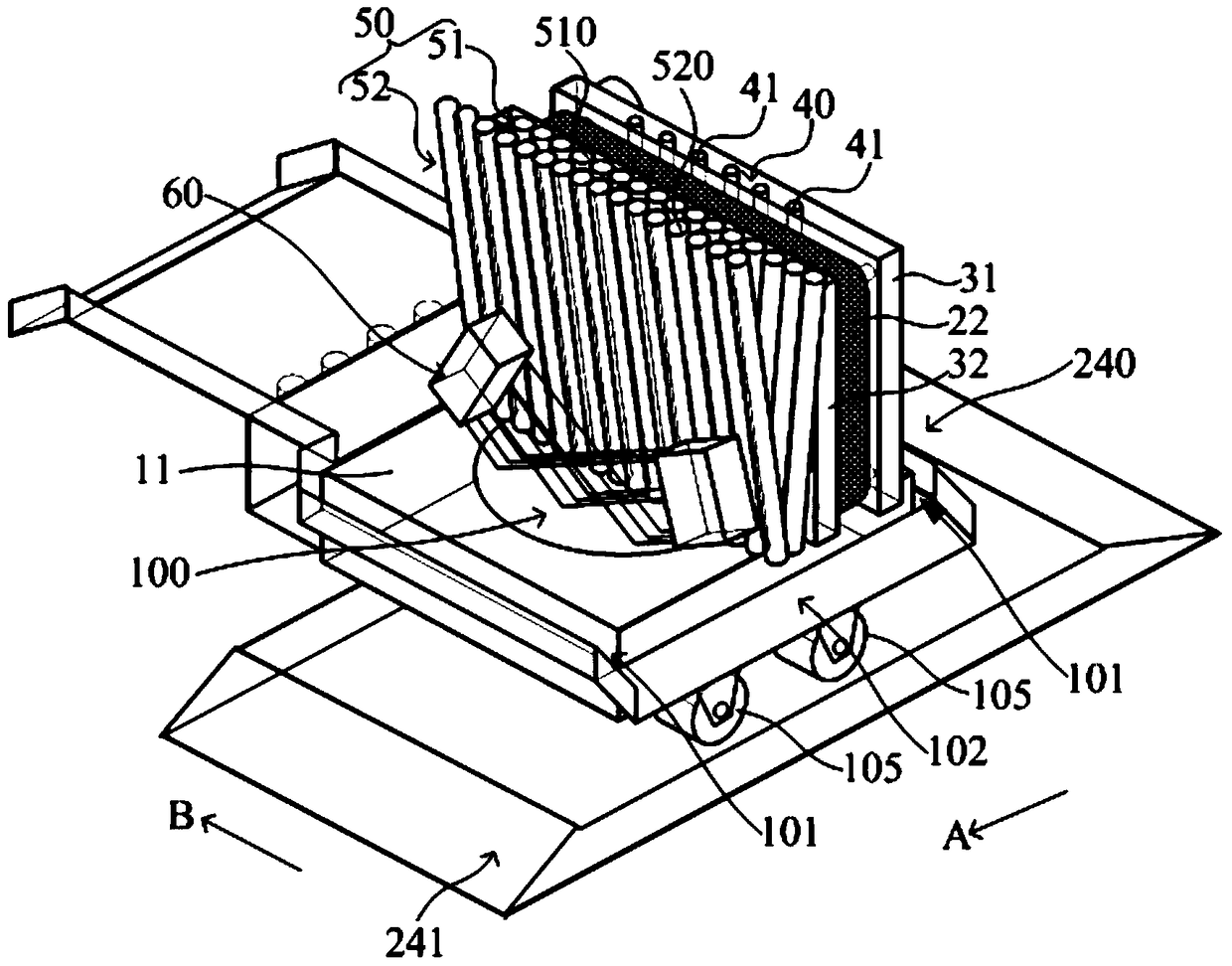

[0080] refer to Figure 2 ~ Figure 4 , the chemical mechanical grinding equipment of the present embodiment comprises:

[0081] The grinding area has a film inlet C and a film outlet D, and the direction from the film inlet C to the film outlet D is the first straight line direction A;

[0082] The first loading table 11 and the second loading table 12, each loading table upper surface is provided with a loading area 100, and in the grinding process, the wafer to be ground is placed on the loading area 100, and the two loading tables can be placed along the first Move in a straight line direction A;

[0083] The grinding mechanism 20 located in the grinding area includes: 4 pulleys 21, a grinding belt 22 sleeved on all the pulleys 21, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com