Liquid crystal glass special-shaped processing method

A liquid crystal glass, special-shaped processing technology, applied in metal processing equipment, manufacturing tools, work carriers, etc., can solve problems such as poor quality, evaluation errors, non-compliance with requirements, etc., to achieve high quality of processed products, high processing efficiency, and avoid damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

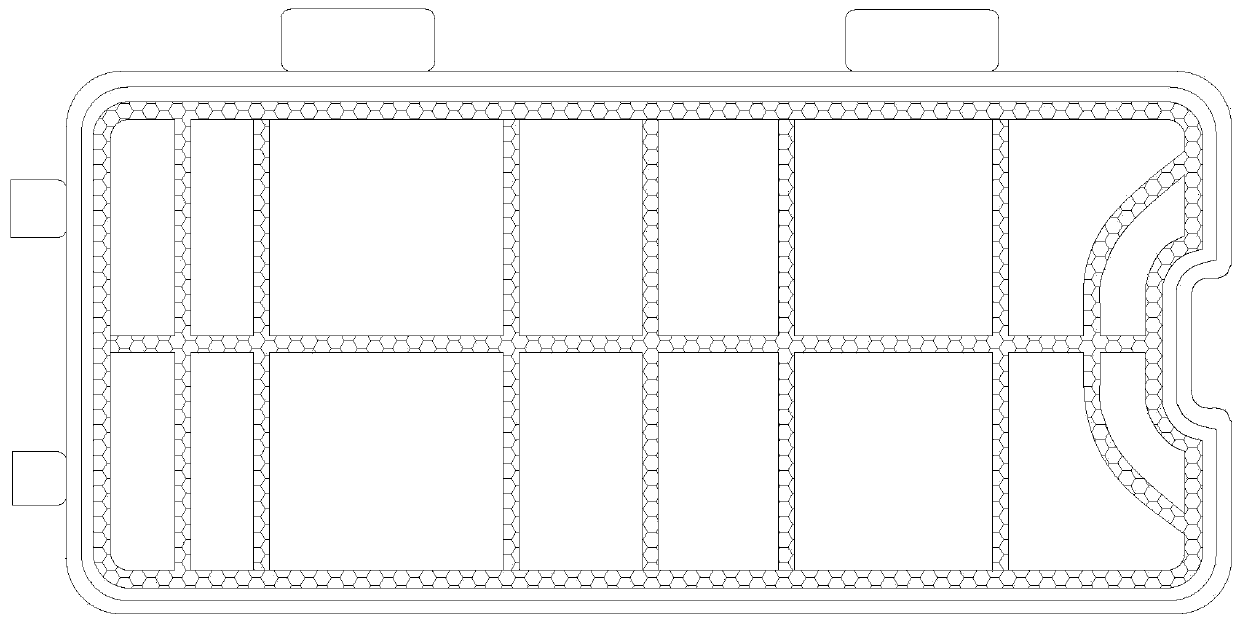

[0024] Such as Figure 1-2 As shown, a liquid crystal glass special-shaped processing method provided by the embodiment of the present invention includes the following steps:

[0025] S1. Move the liquid crystal glass to the positioning jig by means of vacuum adsorption (the way of vacuum absorption can prevent damage to the liquid crystal glass), the vacuum groove on the surface of the positioning jig fixes the liquid crystal glass, and then through the outside of the positioning jig Positioning column for initial positioning;

[0026] S2. Clean up the debris on the surface of the liquid crystal glass, use the CCD camera of Jingdiao machine to extract the image of the liquid crystal glass in the positioning fixture, realize the alignment of the marking points on the liquid crystal glass, and complete the secondary positioning;

[0027] S3. The secondary positioning data is transmitted to the Jingdiao machine. The Jingdiao machine drives the grinding rod to grind the outer ed...

experiment example

[0037] Compared with the previous processing of special-shaped liquid crystal glass (the defect rate of liquid crystal leakage, broken plate, and edge collapse is high, far greater than 0.3%), the liquid crystal glass produced by the application has high precision, and the defects of liquid crystal leakage, broken plate, and edge collapse are high. The defect rate is within 0.3%, especially the improvement of the night crystal leakage problem has largely solved the problem. Through the CPK (process capability index) accuracy verification, a total of 32 products were tested. The data are as follows:

[0038]

[0039]

[0040] Among them, PPK is the performance index, R1-R9 is the chamfer size (in mm) around the processed liquid crystal glass, and the above processing accuracy meets the product requirements.

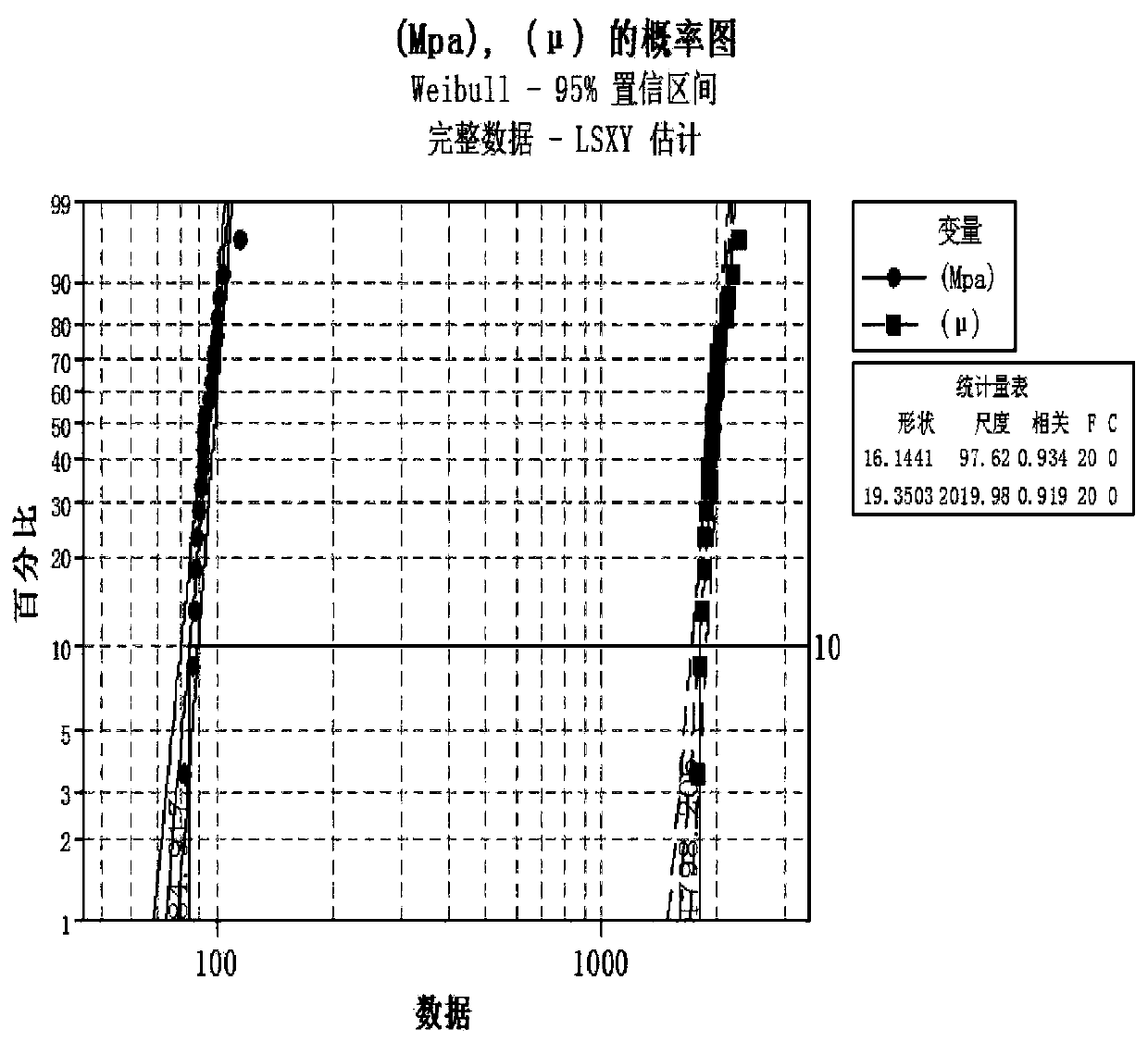

[0041] Then carry out 4PB (four-point bending test) strength verification on the processed liquid crystal glass, and obtain image 3 and Figure 4 Probability diagr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com