Automatic broken yarn identifying and cleaning system of Warp knitting machine

An automatic identification and warp knitting machine technology, applied in the field of warp knitting, can solve the problems that the accuracy of detection cannot be improved, the position of the transmitter cannot be adjusted, and the filaments are easy to mix into the product, so as to avoid floating everywhere and reduce defective products. Occurrence rate, loss reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

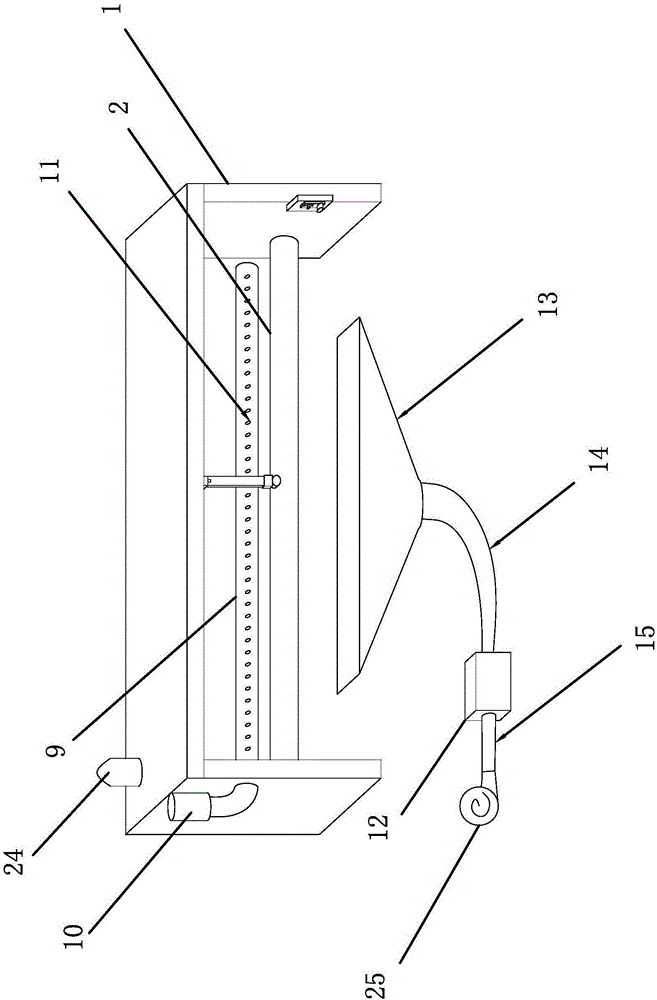

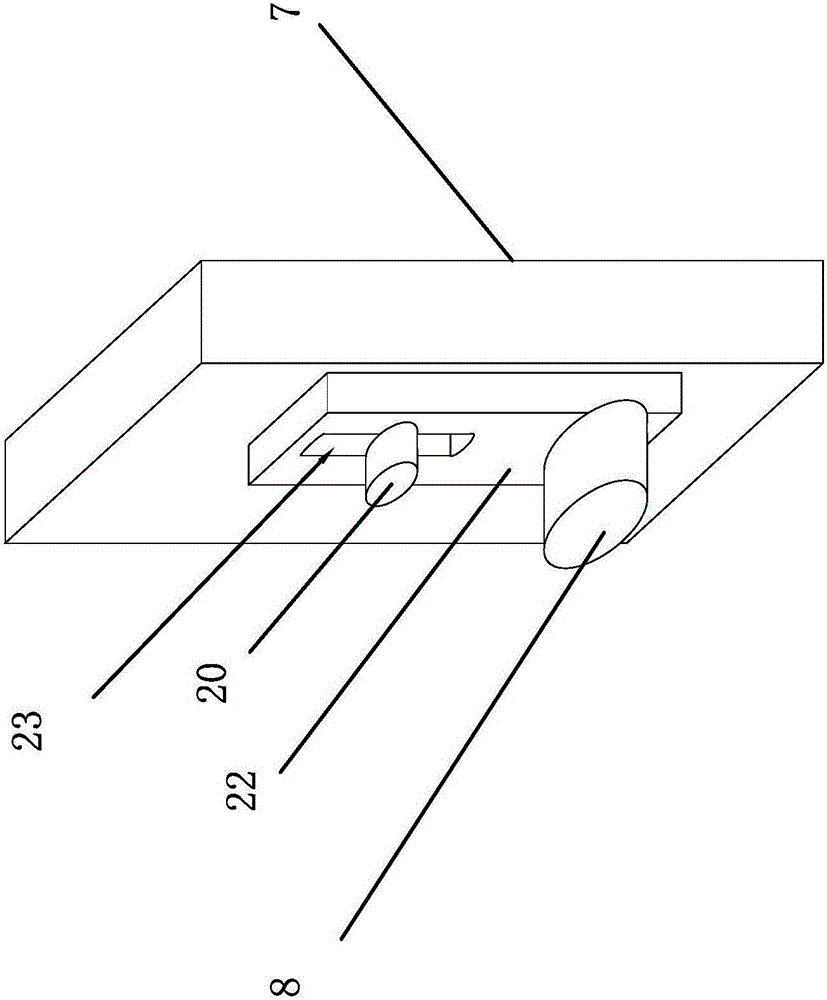

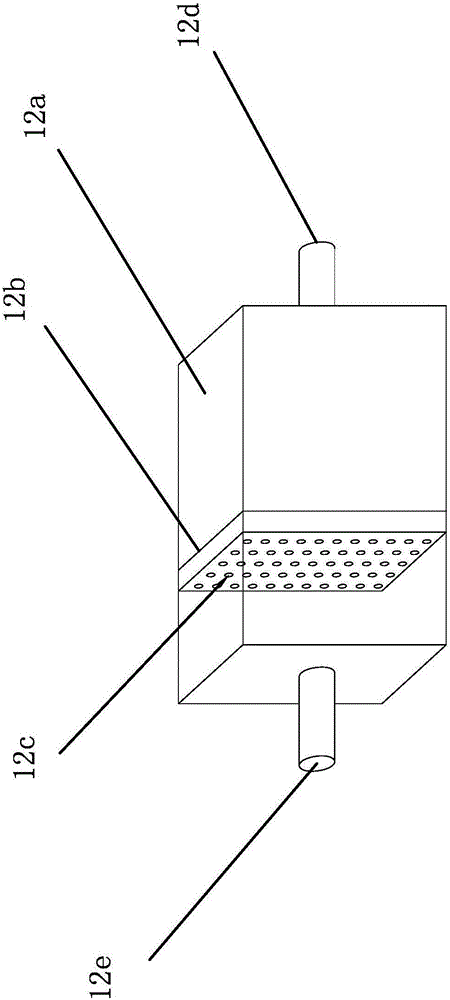

[0030] Such as figure 1 , figure 2 , image 3 , Figure 4 , as shown in Figure 5, the broken wire automatic identification and cleaning system of the warp knitting machine includes a frame 1 and a plurality of transmission rollers 2, and a detection device is provided on the outside of each transmission roller 2, and the detection device includes a middle detection mechanism and a side part The detection mechanism, the middle detection mechanism includes the connecting plate 3, the connecting rod 4 and the hinge seat 5, the connecting plate 3 is fixed on the top of the frame 1, one end of the connecting rod 4 is connected to the lower end of the connecting plate 3 through the adjustment assembly, and the other end is di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com