Automatic closed type water-saving washing machine

A water-saving washing machine, closed technology, applied in the field of washing machines, can solve the problems of waste, poor reliability, failure of washing machines, etc., to achieve the effect of increasing service life, saving drainage time, and improving drainage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

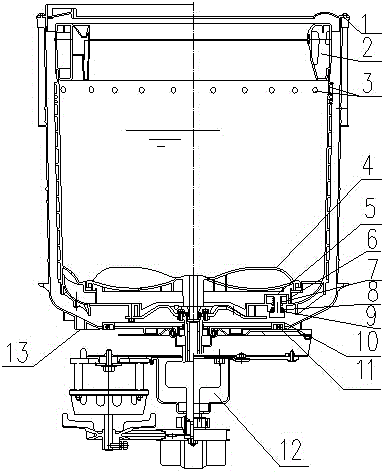

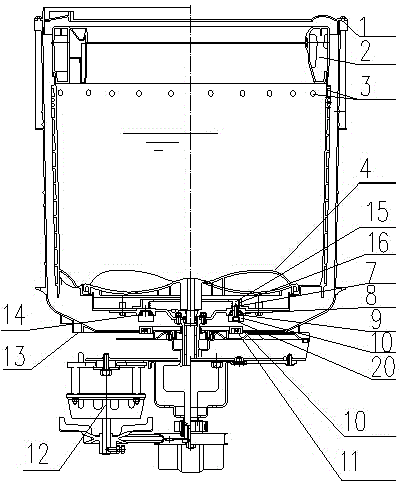

[0017] to combine figure 1 , figure 2 , is a structural schematic diagram of an embodiment of an automatic closed water-saving washing machine according to the present invention, including an outer tub 1 and an inner tub 2, the inner tub 2 is concentrically installed in the outer tub 1, and the upper part of the inner tub 2 near the edge is provided with several water spinners Hole 3, at least one drainage hole 9 is provided at the bottom of the inner barrel 2 through a plunger device that is movably sealed.

[0018] Specifically, the plunger device includes a plunger guide rod 5 arranged in the drain hole 9, the inner barrel 2 is provided with a plunger guide groove 6, and the plunger guide groove 6 is connected to the drain hole 9. The upper part of the plunger guide rod 5 is connected with a sealing member 8, and is installed in the plunger guide groove 6 through the elastic member 7.

[0019] Specifically, the drainage hole 9 is a single inverted funnel-shaped hole or a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com