Method for recognizing engineering sweet spots in shale stratum

A shale and formation technology, applied in the field of identifying engineering sweet spots of gas-bearing shale formations, can solve problems such as describing and defining engineering sweet spots, and achieve the effect of improving development efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

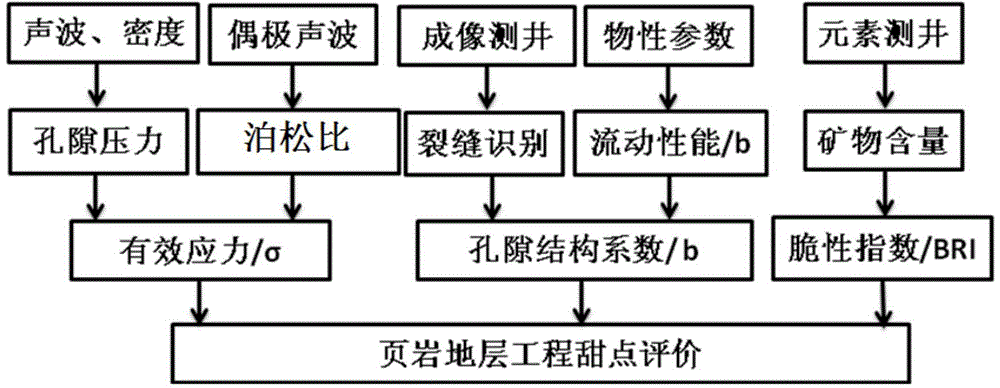

[0060] In this example, the technical ideas for identifying engineering sweet spots in shale formations are as follows: figure 1 As shown, firstly, the pore pressure is calculated according to the acoustic wave and density logging methods, the Poisson’s ratio is calculated by dipole acoustic logging, and the maximum horizontal effective stress of the formation is calculated according to the two values; the experimental data of porosity and permeability can be used to calculate Formation pore structure index; the brittle mineral content is used to calculate the formation brittleness index, and these three parameters are used to determine the shale formation engineering sweet spot coefficient.

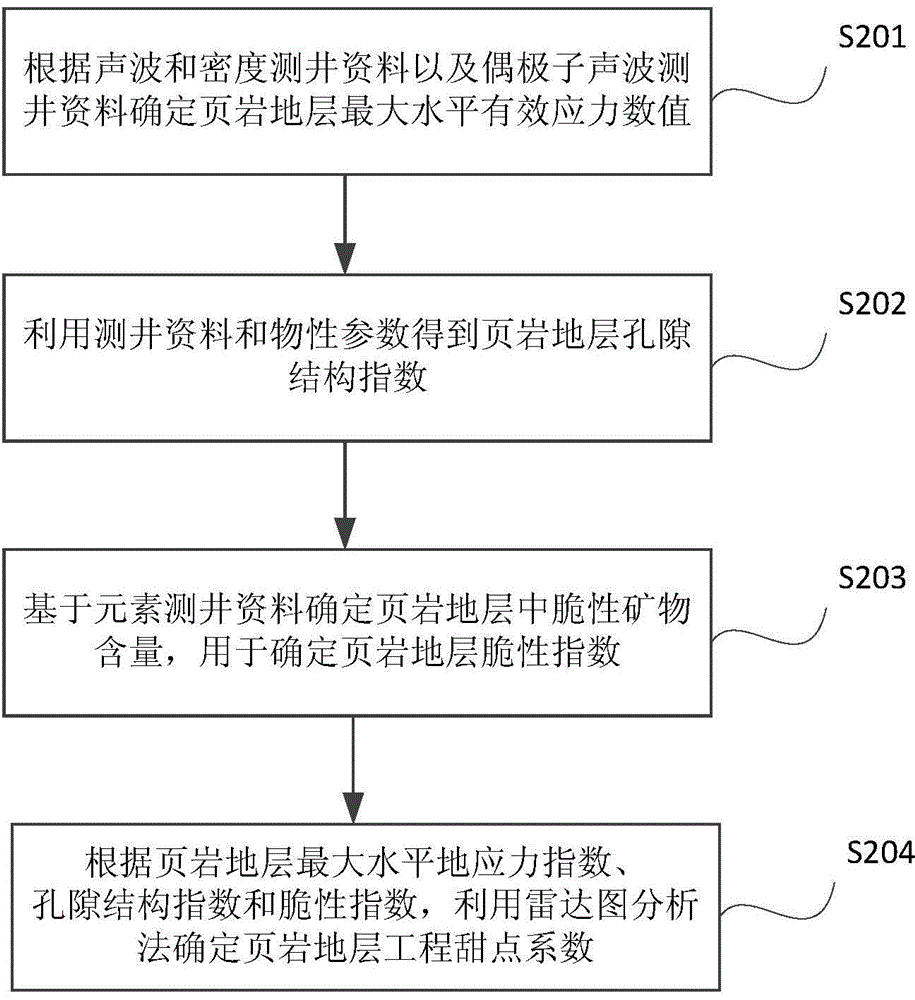

[0061] figure 2 is a flow chart of the steps of the method for identifying engineering sweet spots in shale formations according to this embodiment. The following combination figure 2 The identification method provided in this embodiment will be described in detail.

[0062] In step...

Embodiment 2

[0096]In this embodiment, the logging data of a well in a shale formation in a block in southwest China is used as an example to illustrate the identification results of engineering sweet spots in shale formations.

[0097] The lithology of high-quality shale in this block is mainly composed of yellow-gray shale and silty shale interbedded with thin lenticular limestone. is 40MPa, and the average pore structure index of shale formation is 4.

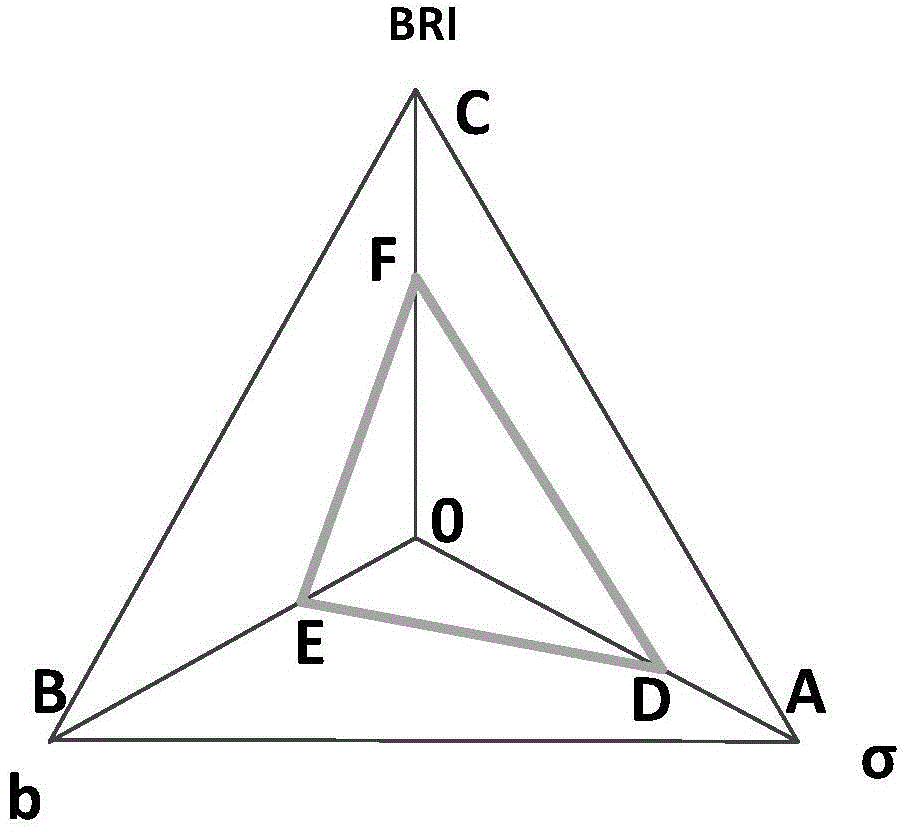

[0098] The extreme values and intervals of engineering sweet spot parameters in this area are as follows: the maximum brittleness index is 80%, the maximum horizontal effective stress interval is 30-45MPa, and the maximum pore structure index is 6. The method of drawing a radar chart after normalizing engineering sweet spot parameters can identify whether the well engineering sweet spot is good or bad.

[0099] Among them, the brittleness index after normalization is BRI=0.7 / 0.8=0.875, and the maximum horizontal effective stress after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com