Design Method of Low Consistency Vane Diffuser

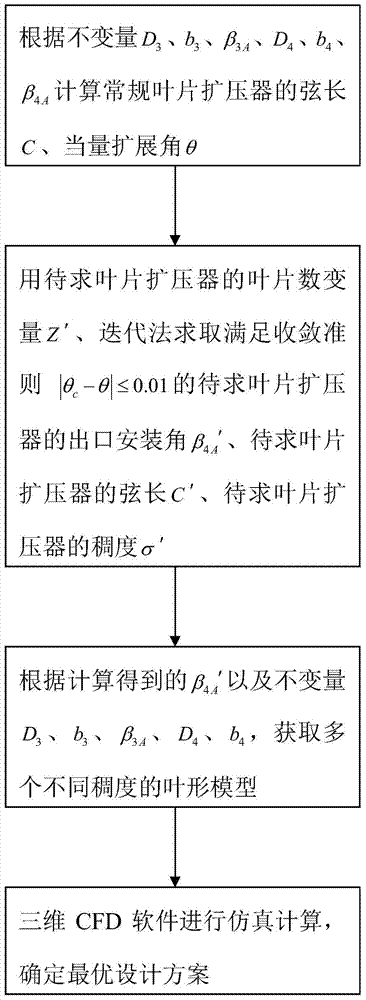

A design method and technology of diffuser, applied in the direction of instrument, calculation, mechanical equipment, etc., can solve the problems of compressor performance, safety impact, narrow curve range, low operation efficiency, etc., to evaluate the pros and cons of the scheme and shorten the design time , the effect of fast 3D simulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

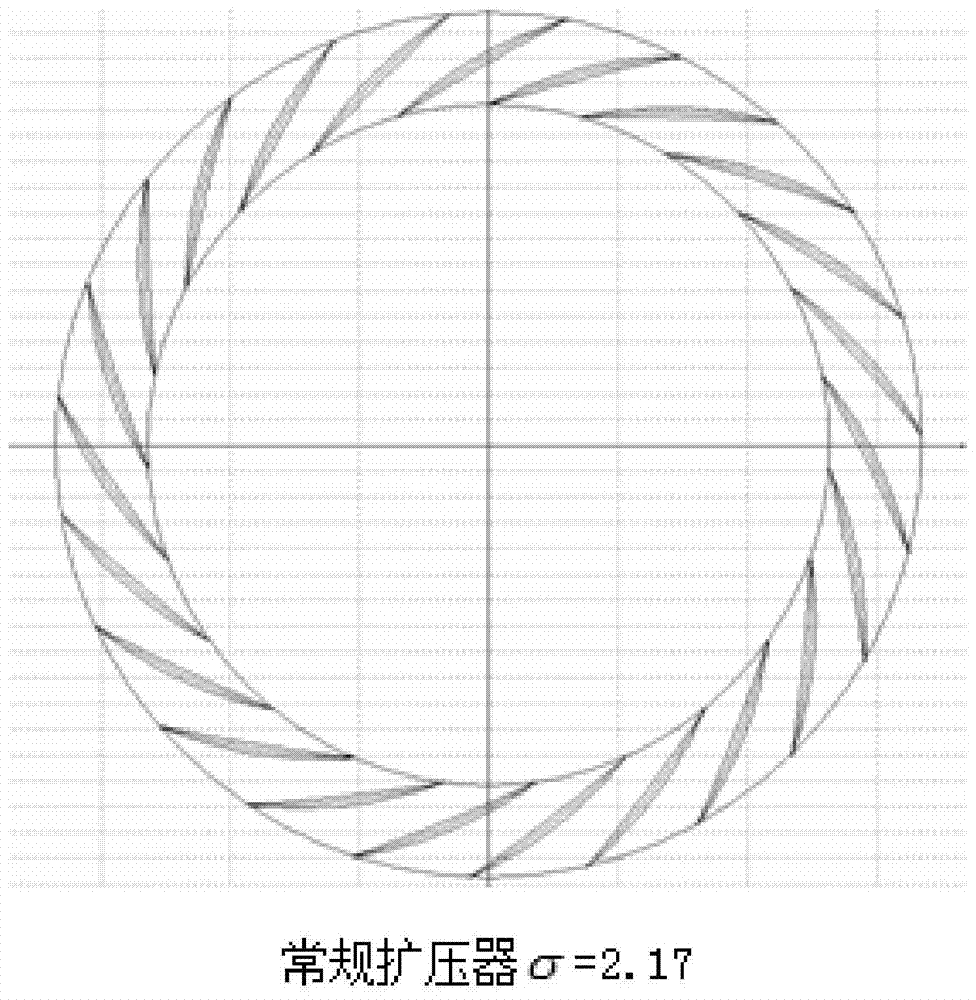

[0031] For designers, the conventional vane diffuser is relative to the vaneless diffuser, that is, a certain number of vanes are evenly distributed along the circumference of the vaneless diffuser wall, so that the airflow flows according to the shape of the vane, The flow condition is better and the flow loss is small. However, in the case of small flow, the vane diffuser is prone to spin out, causing surge. The introduction of low-consistency diffusers is precisely to reduce the sensitivity of conventional vane diffusers to small flow conditions.

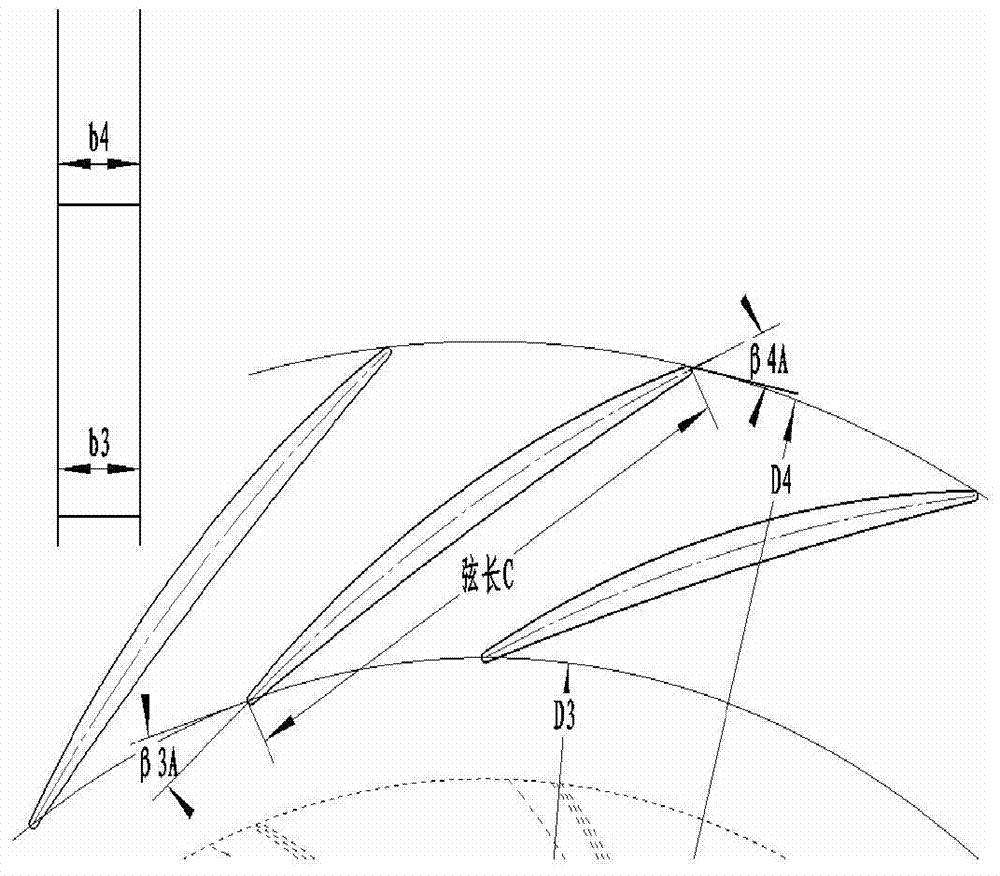

[0032] Such as figure 2 Shown is a schematic diagram of the dimensioning of the diffuser, where D 3 is the inlet diameter of conventional vane diffuser, b 3 is the inlet width of conventional vane diffuser, β 3A For conventional vane diffuser inlet installation angle, D 4 is the outlet dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com