Water area vane shear test platform with bucket truss and installation method

A technology of shear test and installation method, which is applied in the direction of applying stable shear force to test the strength of materials, measuring devices, instruments, etc. Low capacity, unable to meet the normal implementation and other problems, to achieve the effect of reusable safety, convenient transportation, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings. These embodiments are only used to illustrate the present invention, not to limit the present invention.

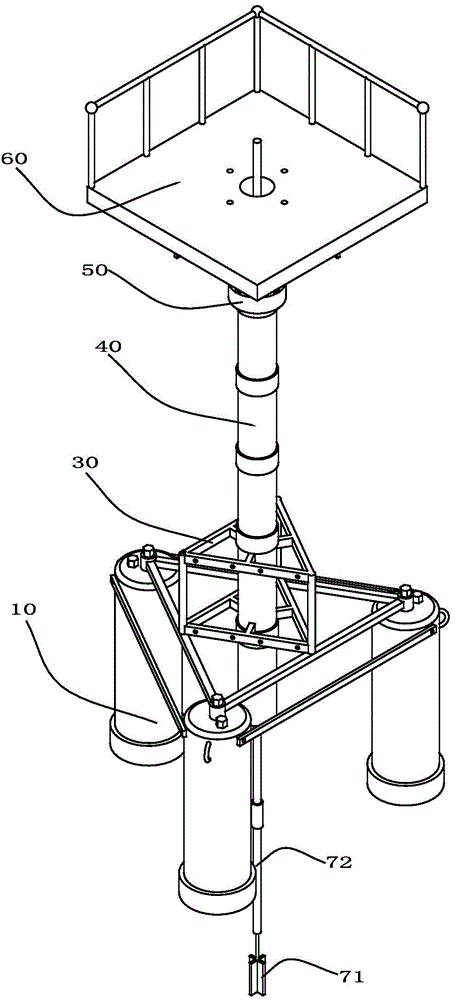

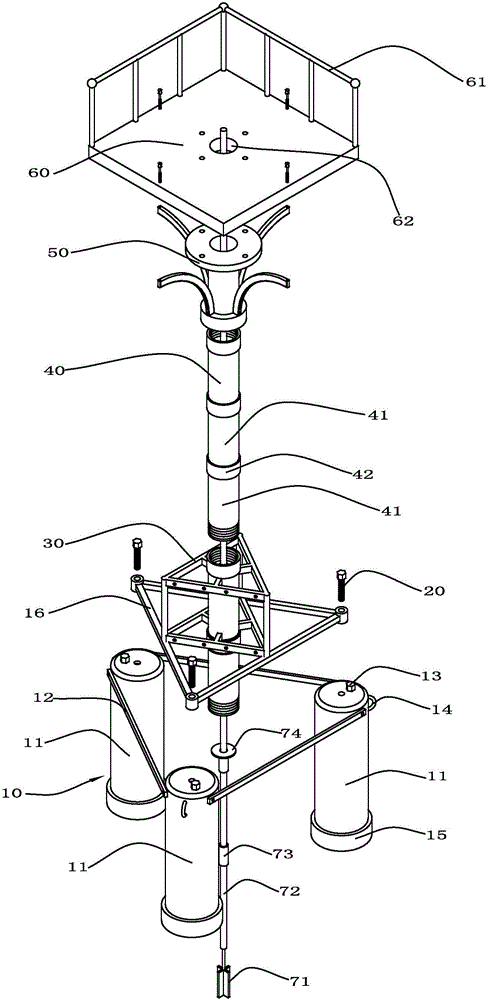

[0048] Such as figure 1 , figure 2 As shown, the present invention has a water area cross plate shear test platform with a bucket truss foundation, including a suction base 10 , a truss module 30 , a conduit 40 , a platform support 50 and an operating platform 60 .

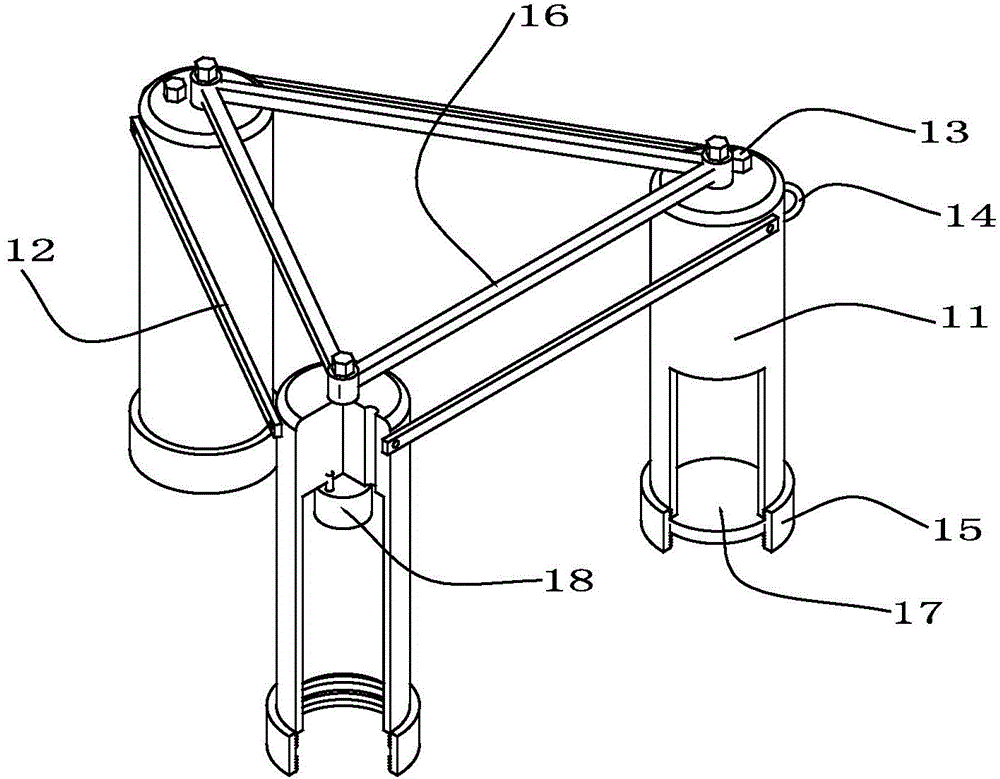

[0049] Wherein, the suction base 10 includes three suction buckets 11 and a fixed frame 16, the bottom of the suction bucket 11 is open, and the top is closed. The fixed frame 16 is in the shape of an equilateral triangle, and the three vertices of the fixed frame 16 are respectively fixedly connected with the tops of the three suction buckets 11 by screws 20;

[0050] The truss module 30 is in the shape of a regular triangular prism and is located ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com