A multi-head high-power DC charging pile system

A DC charging pile, high-power technology, applied in current collectors, electric energy management, electric vehicles, etc., can solve the problem of not being able to charge multiple vehicles at the same time, and achieve the effects of strong versatility, cost saving, and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The technical problem to be solved by the present invention is to provide a multi-tip high-power DC charging pile system, which can perfectly solve the problem that a DC charging pile system with multiple charging gun heads can simultaneously charge different vehicles with different voltage levels. Topology problem. The core idea is to connect (fix) multiple rectifier modules inside the charging pile system in groups, and then let the grouped rectifier module groups freely connect and combine with each other, and then connect with different charging gun heads to form several charging stations with different power. One charging gun, so it can charge different electric vehicles at the same time, meet the requirements of various electric vehicles for charging piles, and meet the requirements of a pile of multi-purpose and simultaneous charging.

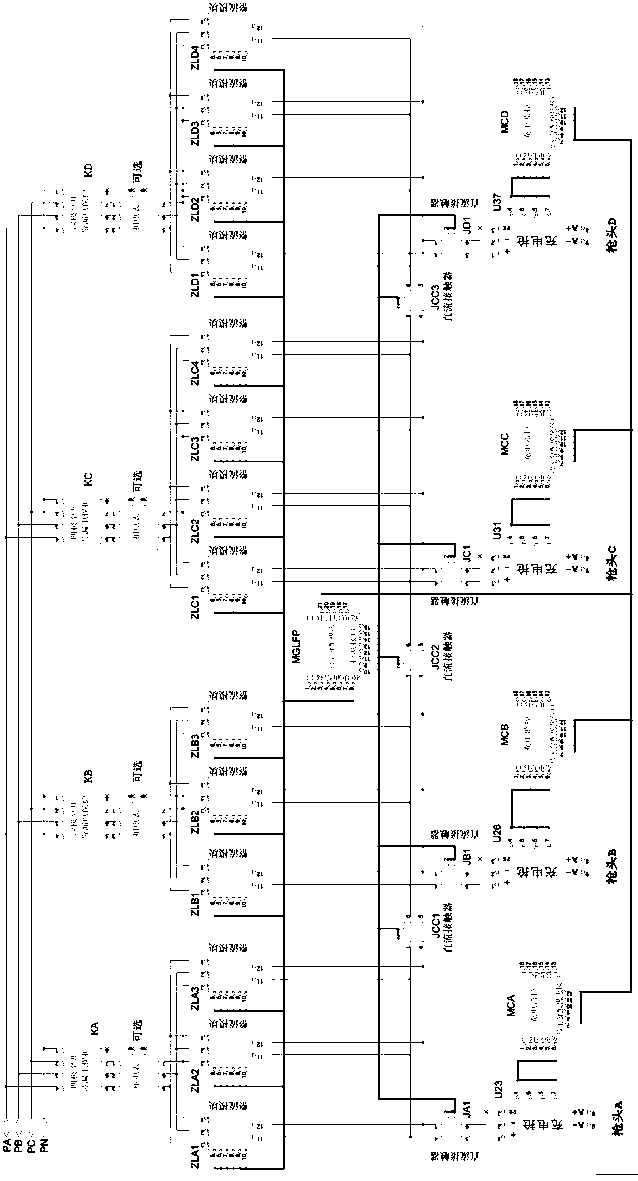

[0027] A multi-tip high-power DC charging pile system provided in this specific embodiment is as follows: figure 1 and figure...

Embodiment 2

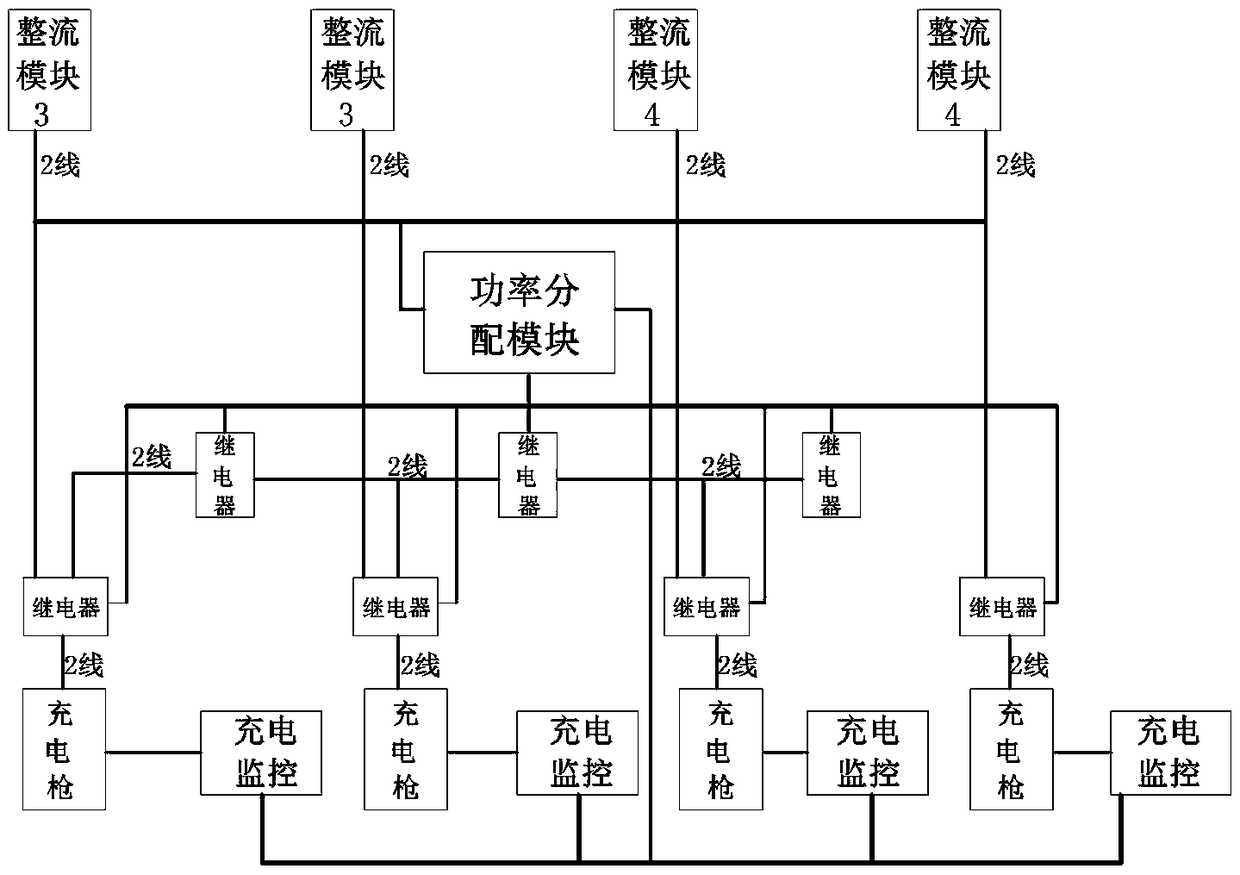

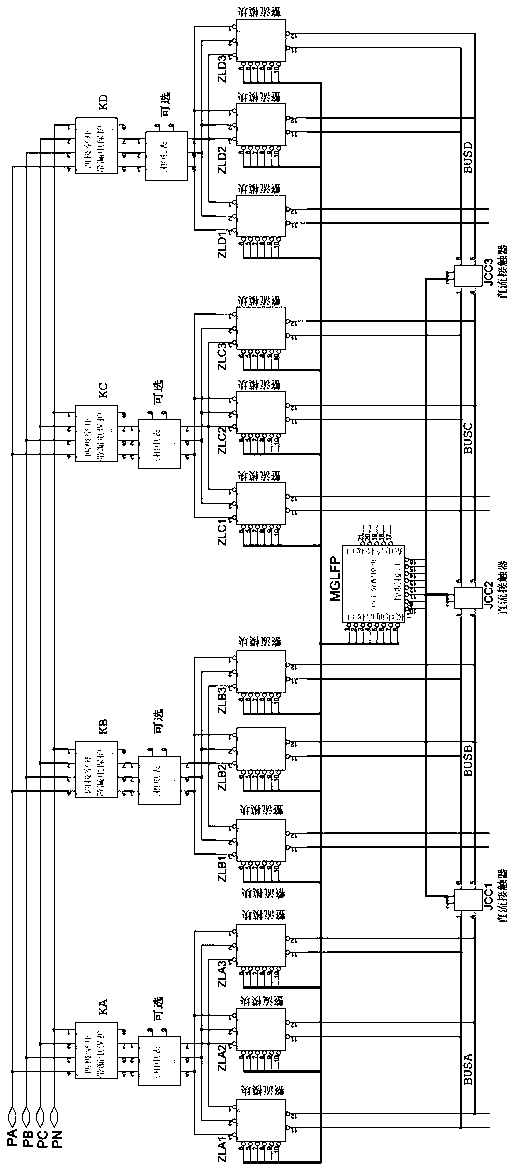

[0039] A multi-tip high-power DC charging pile system provided in this specific embodiment is as follows: Figure 3 to Figure 6 As shown, the difference from Embodiment 1 is that there are 12 rectifier modules in total, and three of them are connected in parallel to form a group. Its output DC busbars are BUSA, BUSB, BUSC, and BUSD, which are respectively connected to charging A gun head, B gun head, C gun head, and D gun head through JA, JB, JC, and JD DC contactors. The communication interface of each module is connected with the power distribution module MGLFP. The DC buses are BUSA, BUSB, BUSC, and BUSD, which are connected through JCC1, JCC2, and JCC3 DC contactors respectively.

[0040] In actual use, if JCC1 is off, JCC2 is off, and JCC3 is off, the DC busbars are separated at this time, and the charging pile becomes four low-power charging guns; JCC1 is closed, JCC2 is off, and JCC3 is closed, and the DC busbars BUSA and BUSB are merged at this time. BUSC and BUSD ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com