A magnetic gear system and method for reducing transmission of torque pulsation

A magnetic gear and energy storage system technology, applied in control systems, permanent magnetic clutches/brakes, electric components, etc., can solve problems such as complex shaft layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

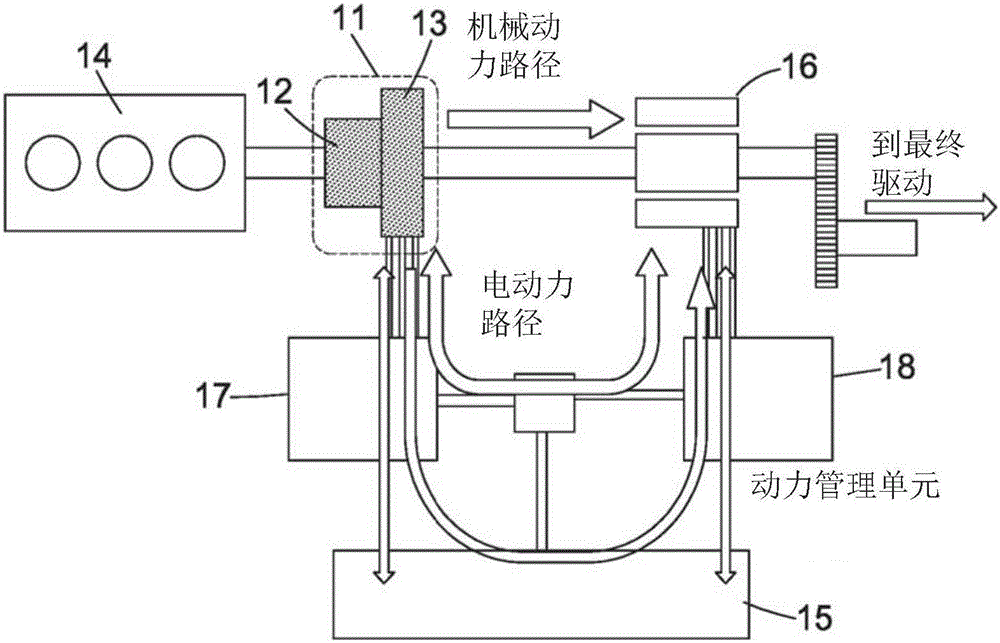

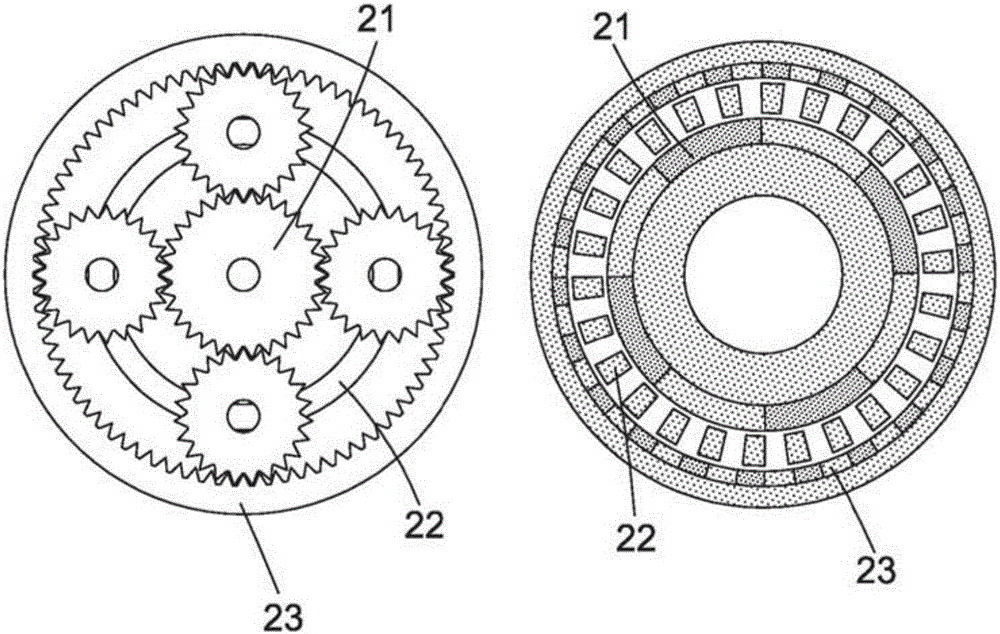

[0177] Embodiment 1: Three-rotor equipment

[0178] refer to Figure 7 and Figure 8 , in this embodiment an external control field interacting with the accompanying field generated by the (permanent magnet) PM array attached to the rotor. This rotor is rotated by means of an external device which preferably carries a stator of windings which surround the stator and are concentric with the gear rotor for packaging, as Figure 7 shown. Figure 7 Shown are a motor / generator stator 71 with windings used as control rotors, a motor / generator rotor 72, a magnetically geared outer PM rotor 73, a pole piece rotor (input or output) 74, and a magnetically geared PM rotor 75 (input or output).

[0179] There are many options for this outer control rotor. For example:

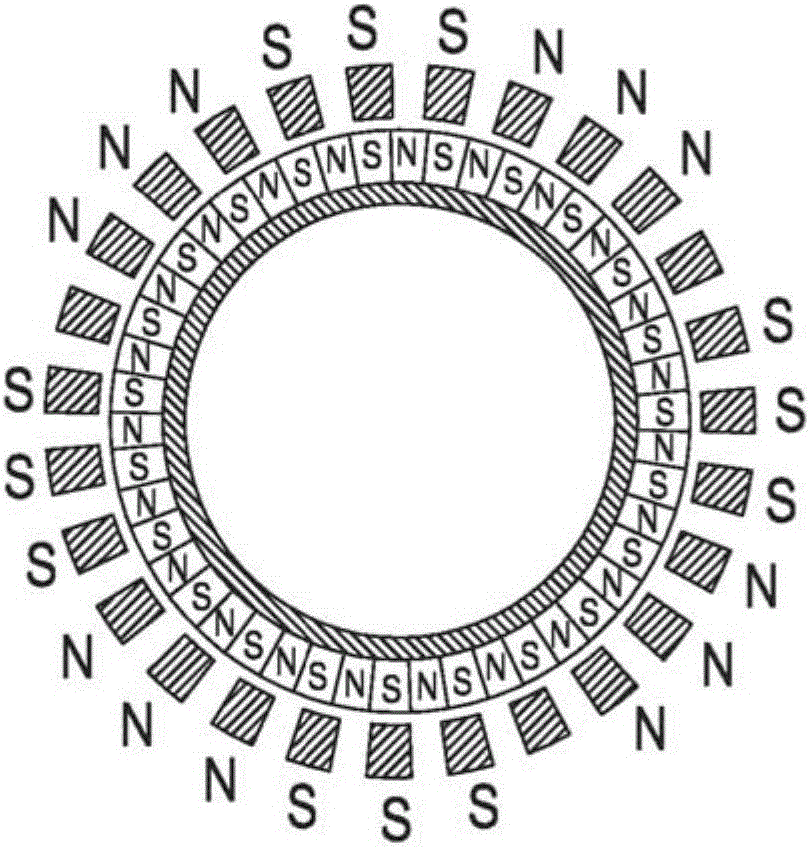

[0180] A. PM inner and outer - each array has a different number of poles than the back iron. This enables independent optimization of gears and motor / generators, as Figure 8 shown.

[0181] B. The PM has the sam...

Embodiment approach 2

[0193] Embodiment 2: two-rotor equipment

[0194] In this embodiment, the control component is not a physical rotor, but is implemented by coupling the accompanying field with the field controlling the stator. Current power split components consist of an array of permanent magnets (usually the output rotor) and a pole piece modulation array (usually the input rotor). The accompanying field generated by the magnetic field generated by the PM interacting with the pole pieces is coupled with the spatial field generated by a set of windings to generate torque and hence gearing operation as Figure 12 shown. If the current in the winding is fixed, the gear works with a fixed gear ratio. The external field is rotated by supplying a temporally shifted current (typically a three-phase 120-degree shifted current) to a spatially distributed winding (typically a three-phase 120-degree-shifted winding). The gear ratio is then changed as described above.

[0195] One possible way to ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com