Irrigating aspirator

A suction device and suction tube technology, applied in the field of medical devices, can solve problems such as affecting the progress of the operation and not being able to be sucked away

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

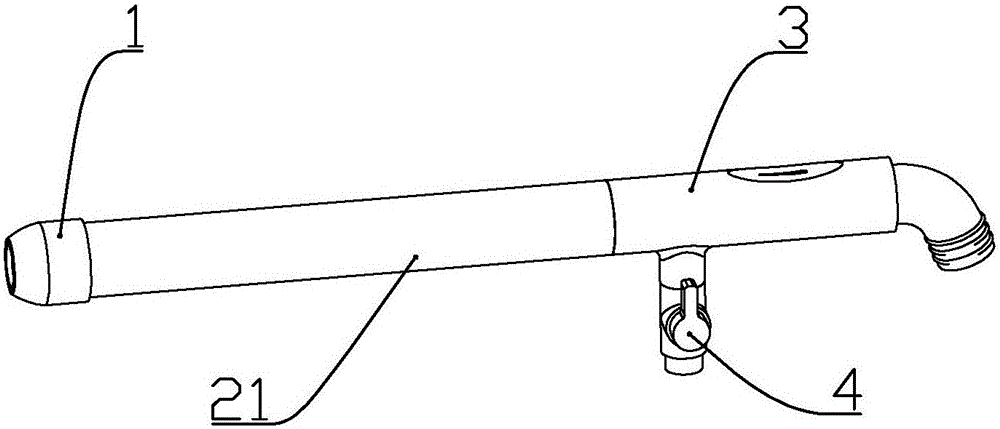

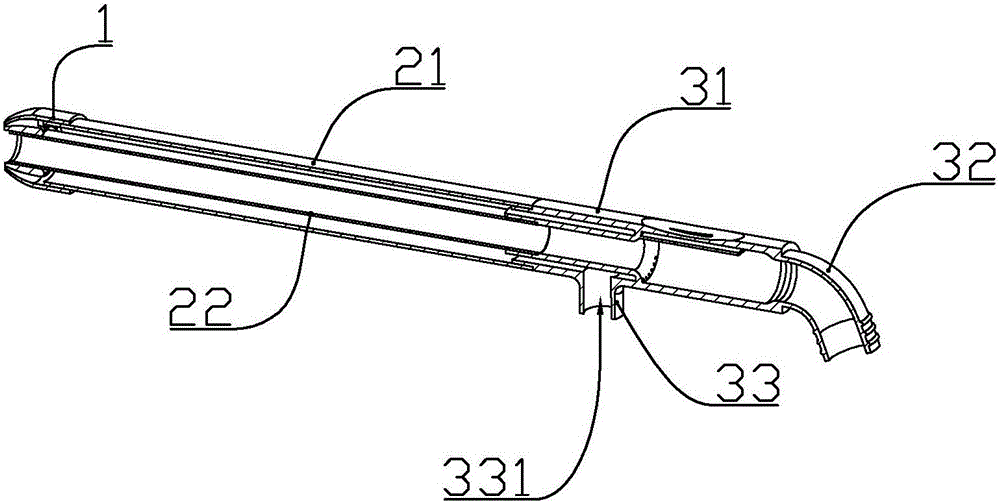

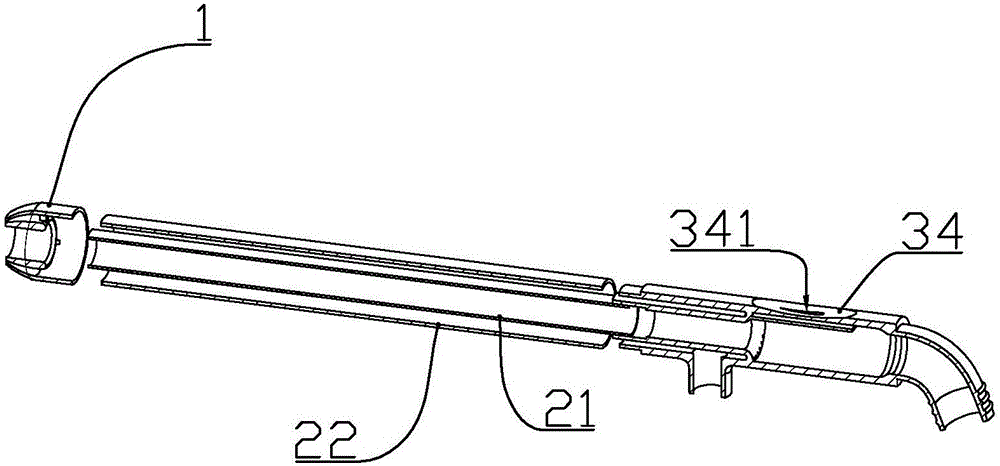

[0025] according to Figure 1 to Figure 6 As shown, a flushing aspirator described in this embodiment includes a nozzle assembly 1, which is inserted into the outer tube 21 and the inner tube 22 at the rear end of the nozzle assembly, and is fixedly connected to the rear end of the outer tube and the inner tube. A handle assembly 3 and a valve 4 fixedly connected to the lower end of the handle assembly; the spray head assembly includes an outer pipe connection sleeve 11 socketed with the outer pipe, and an inner pipe connection sleeve socketed with the inner pipe 12. Three connecting ribs 14 uniformly distributed in the circumferential direction are formed between the outer tube connecting sleeve and the inner tube connecting sleeve; Ring-shaped water spout 13; a suction hole 121 is formed in the middle of the inner pipe connection sleeve; the handle assembly includes a handle body 31, and a negative pressure control part 34 formed at the rear of the handle body is formed on t...

Embodiment 2

[0031]A flushing aspirator described in this embodiment includes a spray head assembly 1, an outer tube 21 and an inner tube 22 inserted at the rear end of the spray head assembly, and a handle assembly 3 fixedly connected to the rear end of the outer tube and the inner tube And the valve 4 fixedly connected to the lower end of the handle assembly; the spray head assembly includes an outer pipe connection sleeve 11 socketed with the outer pipe, and an inner pipe connection sleeve 12 socketed with the inner pipe; the Three connecting ribs 14 uniformly distributed along the circumferential direction are formed between the outer pipe connecting sleeve and the inner pipe connecting sleeve; an annular water spray is formed between the outer pipe connecting sleeve and the front end of the inner pipe connecting sleeve. port 13; a suction hole 121 is formed in the middle of the inner tube connecting sleeve; the handle assembly includes a handle body 31, a negative pressure control part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com