Lateral extrusion adjustment mechanism for copper processing extruder

An adjustment mechanism and extruder technology, applied in the field of copper processing, can solve the problems of troublesome mold loading and unloading, increased production costs, and limited scope of molds for supporting mechanisms, and achieve the effects of wide range of mold sizes, reduced difficulty of loading and unloading, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

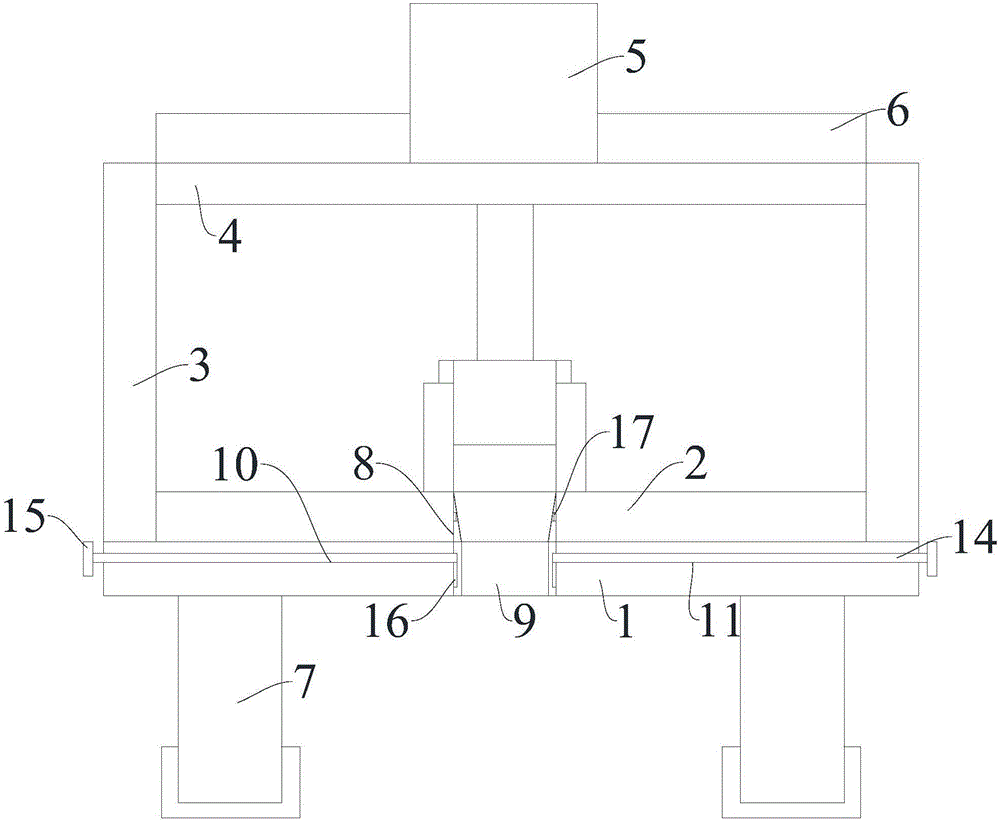

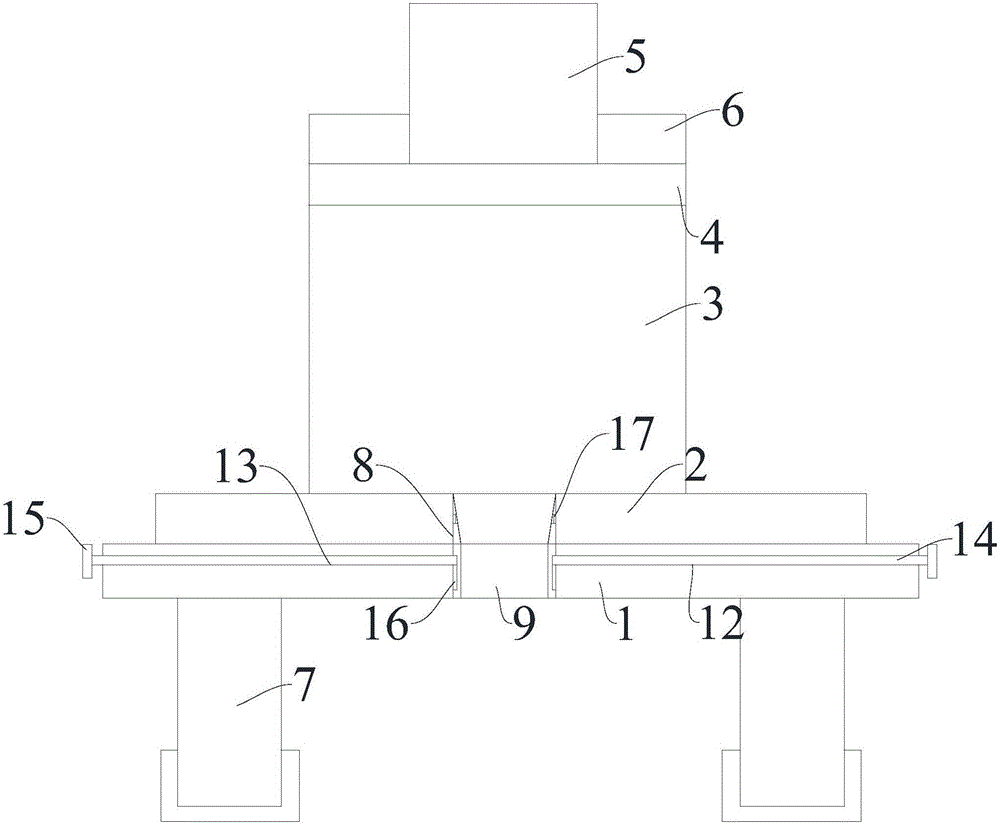

[0016] Embodiment: the lateral thread limit rod 14 inside the left horizontal internal screw hole 10 and the right horizontal internal screw hole 11 extends into the first limit groove 16 through rotation; the front horizontal internal screw 12 and the rear horizontal internal screw The lateral thread limit rod 14 inside the hole 13 extends into the second limit groove 17 through rotation, and the extrusion mold 9 is fixedly installed by multi-directional extrusion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com