Low-noise metal cutting production line

A metal cutting and production line technology, applied in metal sawing equipment, metal processing equipment, metal processing machinery parts, etc., can solve problems such as adverse physical and mental health, affecting work efficiency, staff discomfort, etc., to prevent sound leakage and improve sound insulation effect, the effect of reducing cutting noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

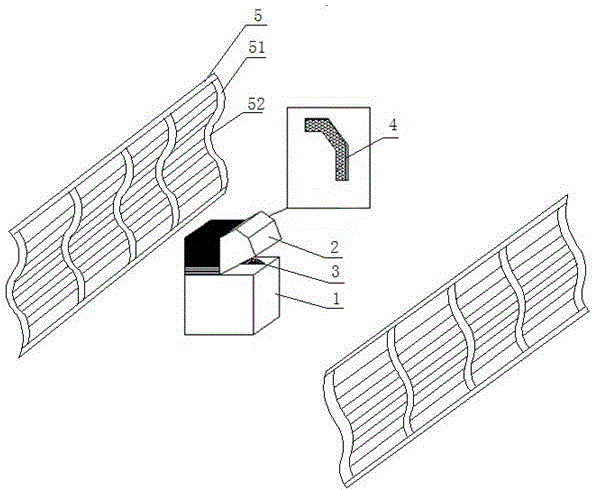

[0021] Such as figure 1 Shown: a low-noise metal cutting production line, including a cutting machine body 1, a protective cover 2 set on the cutting machine body 1 and a saw blade 3 set in the protective cover 2, the lower part of the saw blade 3 is set on the cutting machine body 1, the cutting part of the saw blade 3 is set in the protective cover 2; the protective cover 2 is a box structure, the top of the protective cover 2 is provided with a water injection port, and the protective cover 2 is used to hold soap bubbles; the protective cover 2 is facing the saw That side of the sheet 3 is laid with a layer of soundproofing material 4 .

[0022] In this embodiment, in order to realize that the metal cutting production line can greatly reduce the cutting noise on the basis of low cost, the protective cover 2 is designed as a box st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com