Toning lotion bottle clamp

A water bottle and fixture technology, applied in manufacturing tools, workpiece clamping devices, printing, etc., can solve the problem of high production costs and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

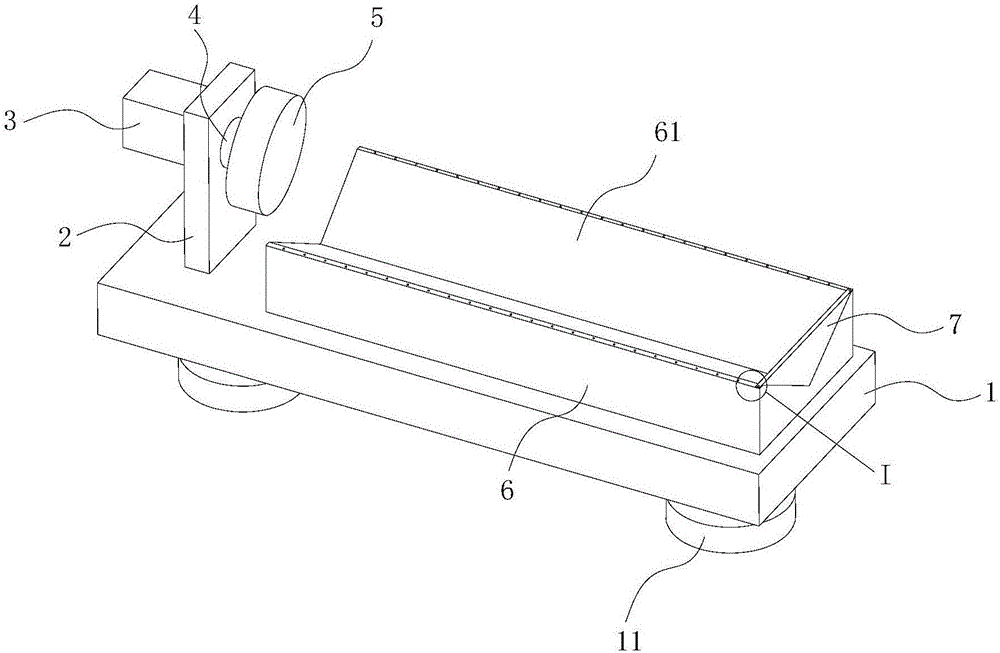

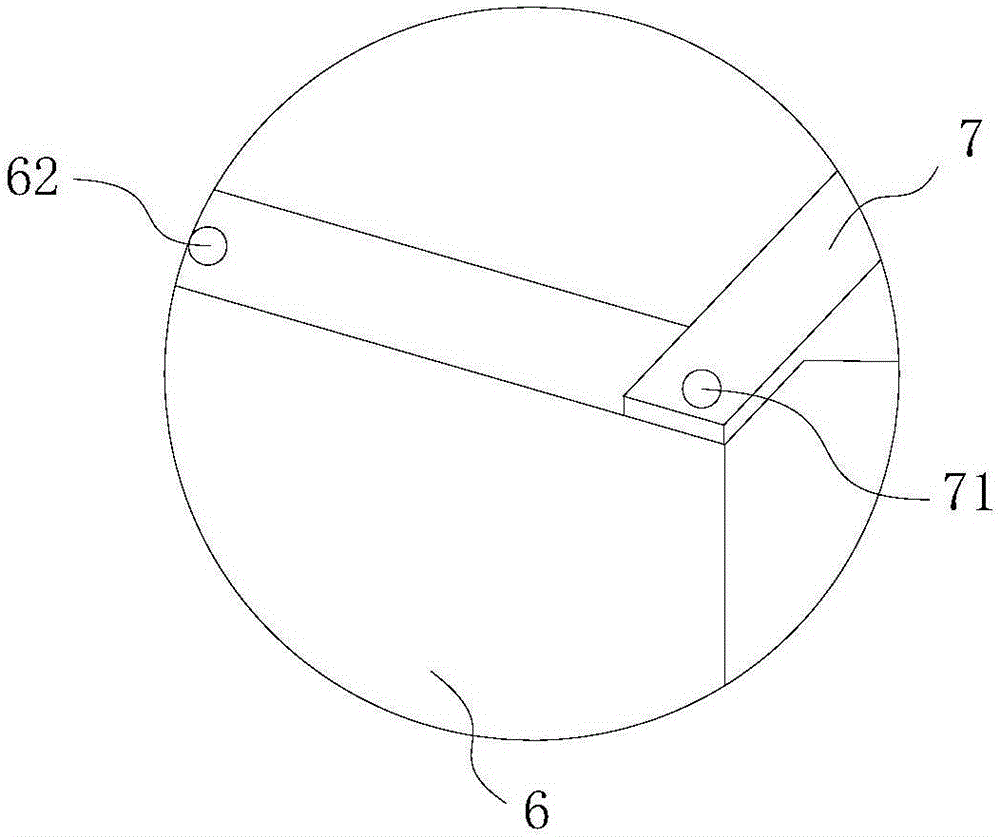

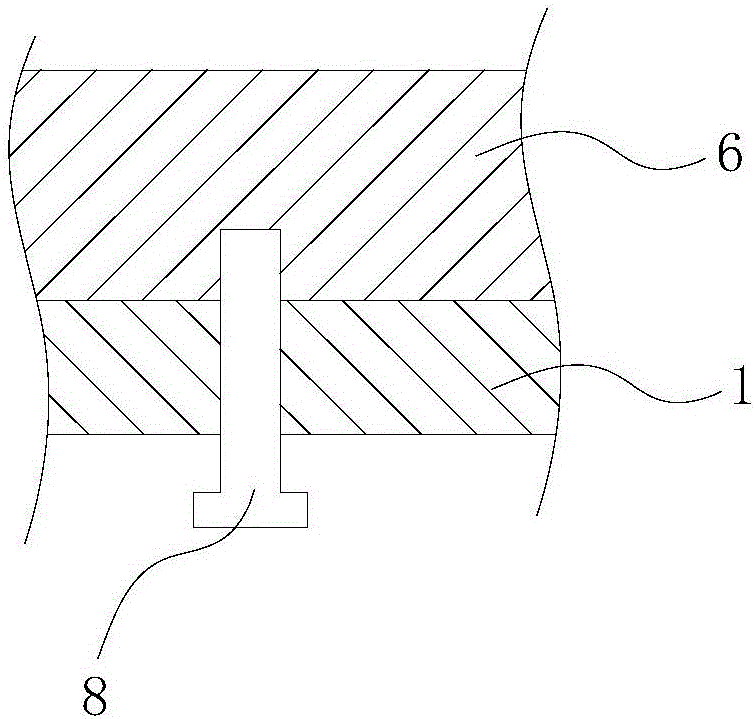

[0020] Such as figure 1 As shown, the present embodiment provides a fixture for a lotion bottle, including a workbench 1, one end of the workbench 1 is provided with a fixed plate 2, and one side of the fixed plate 2 is provided with a drive motor 3, and the drive motor 3 Extended end runs through fixed plate 2 and is connected with connecting post 4, and one end of described connecting post 4 not connected drive motor 3 extended end is detachably connected with positioning post 5, and described drive motor 3 is connected to controller (not shown in the figure). show). Align the mouth of the cosmetic bottle with the positioning column 5, and insert the positioning column 5 into the mouth of the cosmetic bottle to realize the clamping of the cosmetic bottle. At the same time, the controller can cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com