A kind of suction glove mold

A technology of gloves and molds, which is applied to household appliances, other household appliances, and household components, etc., can solve problems such as waste of human resources, low production efficiency, and increased cumbersome procedures, so as to improve automation and mechanization, reduce labor costs, and simplify complicated procedures. Process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Now the present invention is further described in conjunction with description of drawings and embodiments:

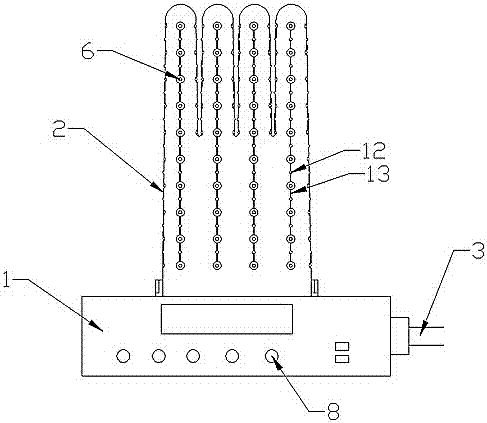

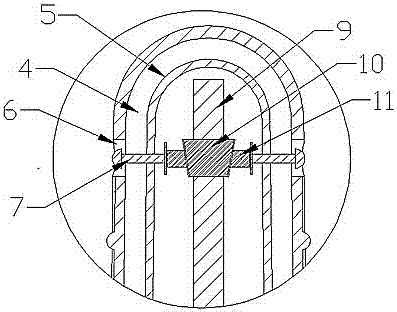

[0017] refer to figure 1 and figure 2 , a kind of air-pumping glove mold, comprising a base 1, a vacuum device and a glove mold 2, wherein: one side of the base 1 is provided with an air outlet 3, which is connected with the vacuum device, and the glove mold 2 is arranged on the side of the base 1 On the top surface, the glove mold 2 is provided with a gas flow chamber 4, the outside of the gas flow chamber 4 is the outer wall of the glove mold 2, and the inner side is the support body 5 of the glove mold 2, and the outer wall of the glove mold 2 is provided with Several air extraction holes 6 communicate with the gas flow chamber 4, and the support body 5 is provided with a support rod 7 at the center of the corresponding air extraction hole 6. The support rod 7 is a telescopic support rod, and a support ball is provided at the end of the support rod 7 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com