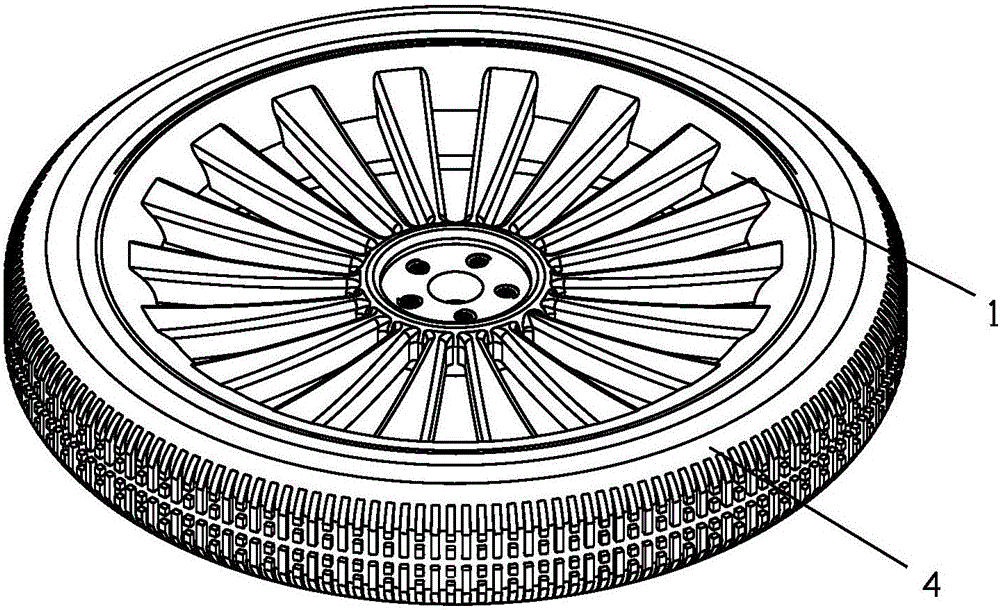

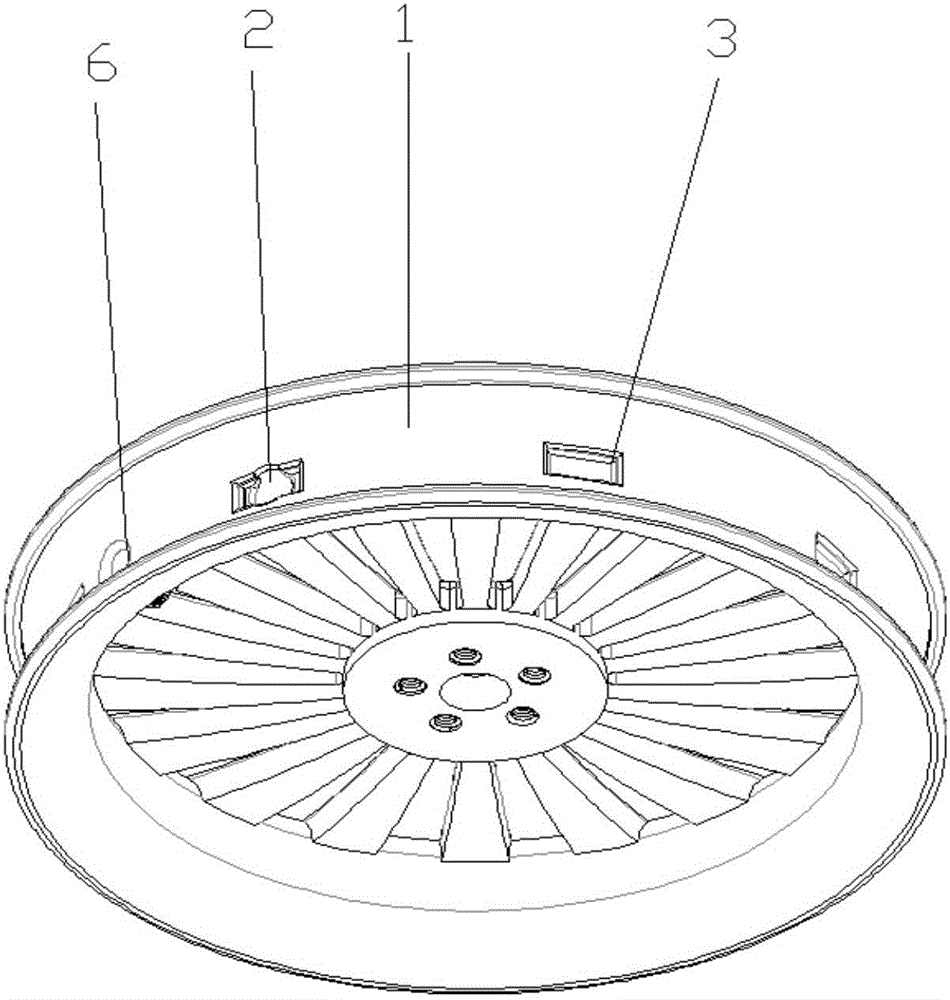

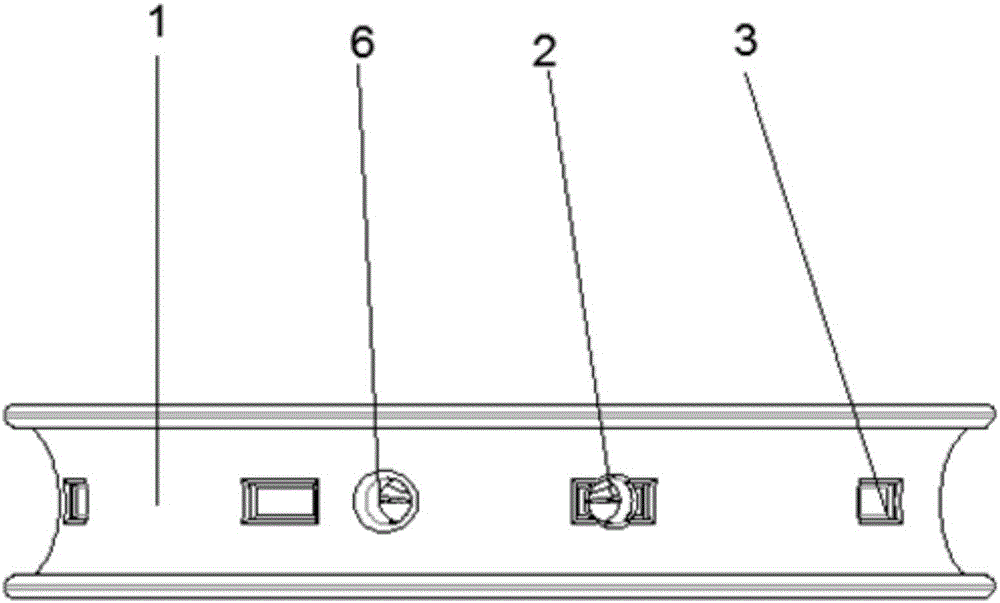

Novel inflation-free tire capable of preventing puncture and tire burst

A kind of explosion-proof tire, no inflation technology, applied in non-pneumatic tires, special tires, tire parts and other directions, can solve the problems of air leakage, normal driving, trouble and cumbersome maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The production process of the colloid is as follows: mix and stir vinyl silicone oil, white carbon black and hydroxyl silicone oil, turn on the heating switch immediately after forming a large group, and start vacuuming for 45-60 minutes when the actual temperature rises to 100°C, etc. When the actual temperature rises to 130°C, turn off the heating switch and cool down.

Embodiment 2

[0023] The production process of the colloid is as follows: mix and stir vinyl silicone oil, white carbon black, hexamethyldisilazane and water, turn on the heating switch immediately after forming a large group, and start pumping when the actual temperature rises to 130°C Vacuum for 45 to 60 minutes, and when the actual temperature rises to 150°C, turn off the heating switch and cool down.

Embodiment 3

[0025] The components of the colloid include: 60% to 75% of white oil, 10% to 20% of rubber powder, and 15% to 30% of white carbon black. Stir while heating, and control the temperature at 150°C to 230°C. After it is completely dissolved, inject it into the gap between the wheel hub and the tire at 1 to 5 atmospheres or use an injection molding machine, and wait for cooling.

[0026] Finally, it should be stated that:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com