Fixing device suitable for high-torque transverse thrusting rod and used in vehicle

A technology of lateral thrust rods and fixing devices, which is applied to vehicle components, transportation and packaging, and cantilever mounted on pivots, etc., which can solve the problems of chassis frame beam stress concentration, strength damage of fixing devices, and impact on driving safety, etc. Achieve the effect of uniform structural stress, increased strength reliability, and good integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

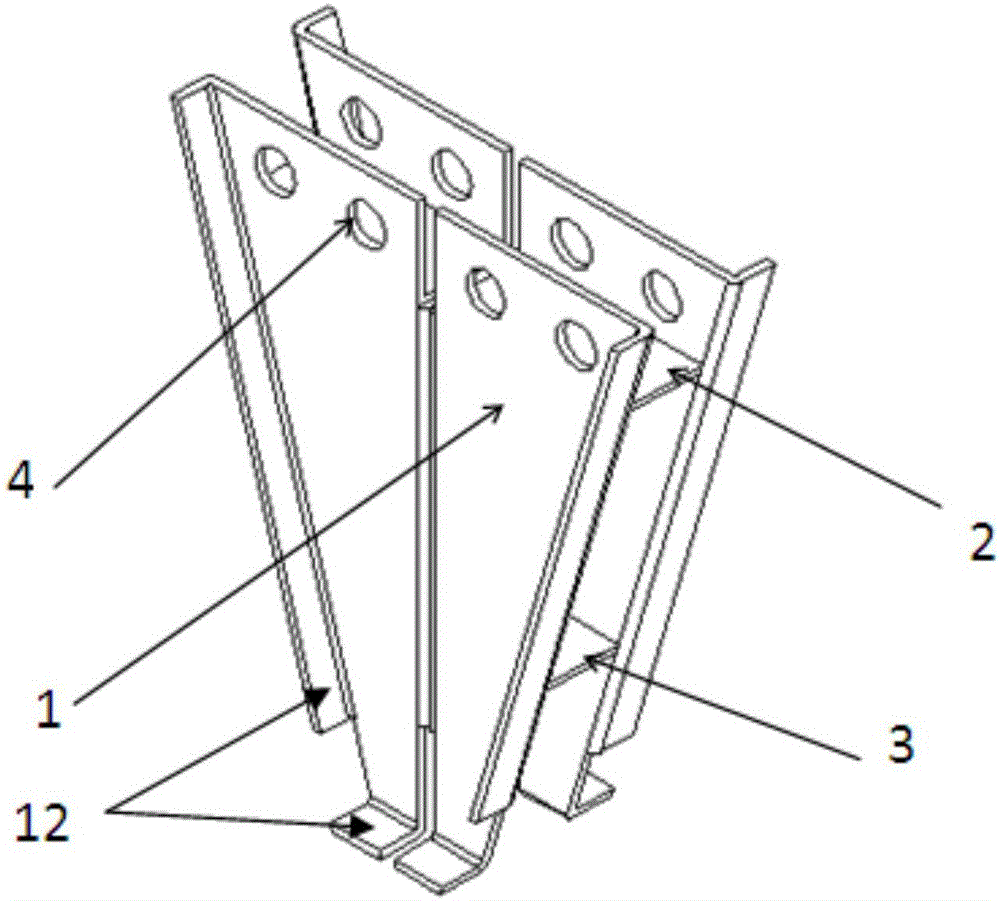

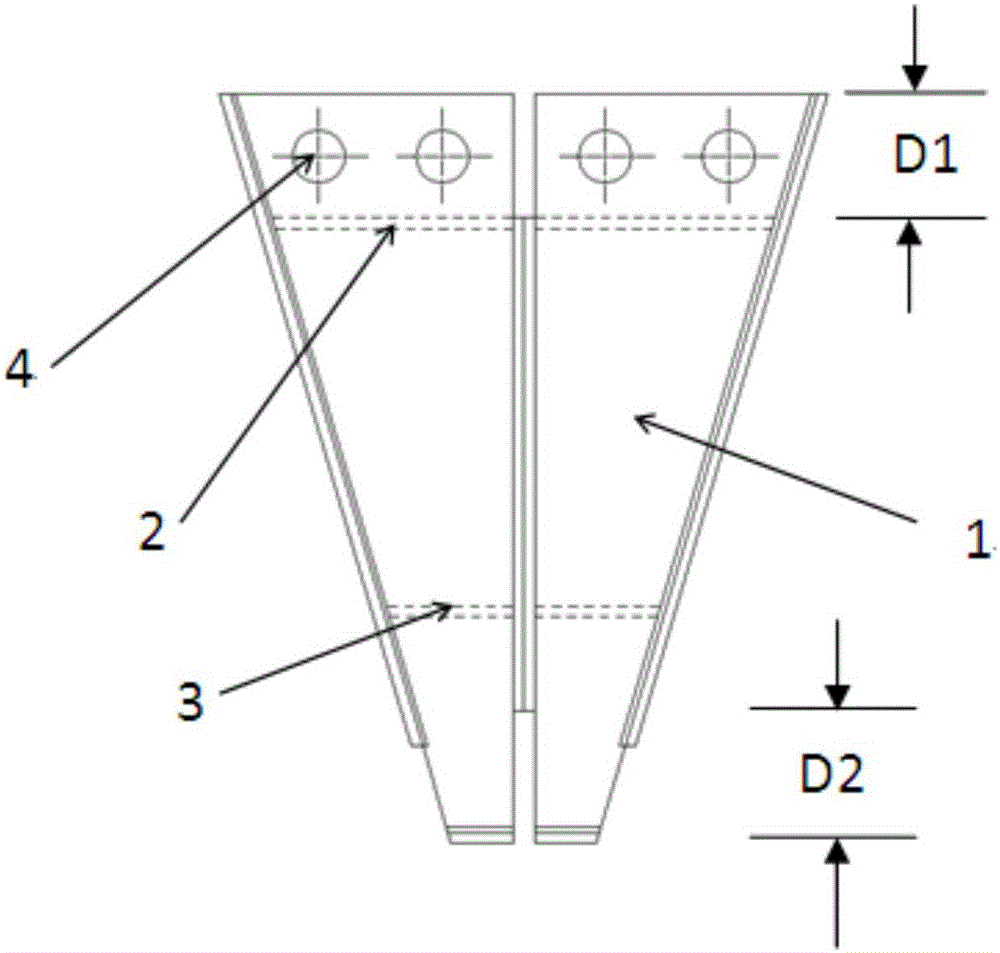

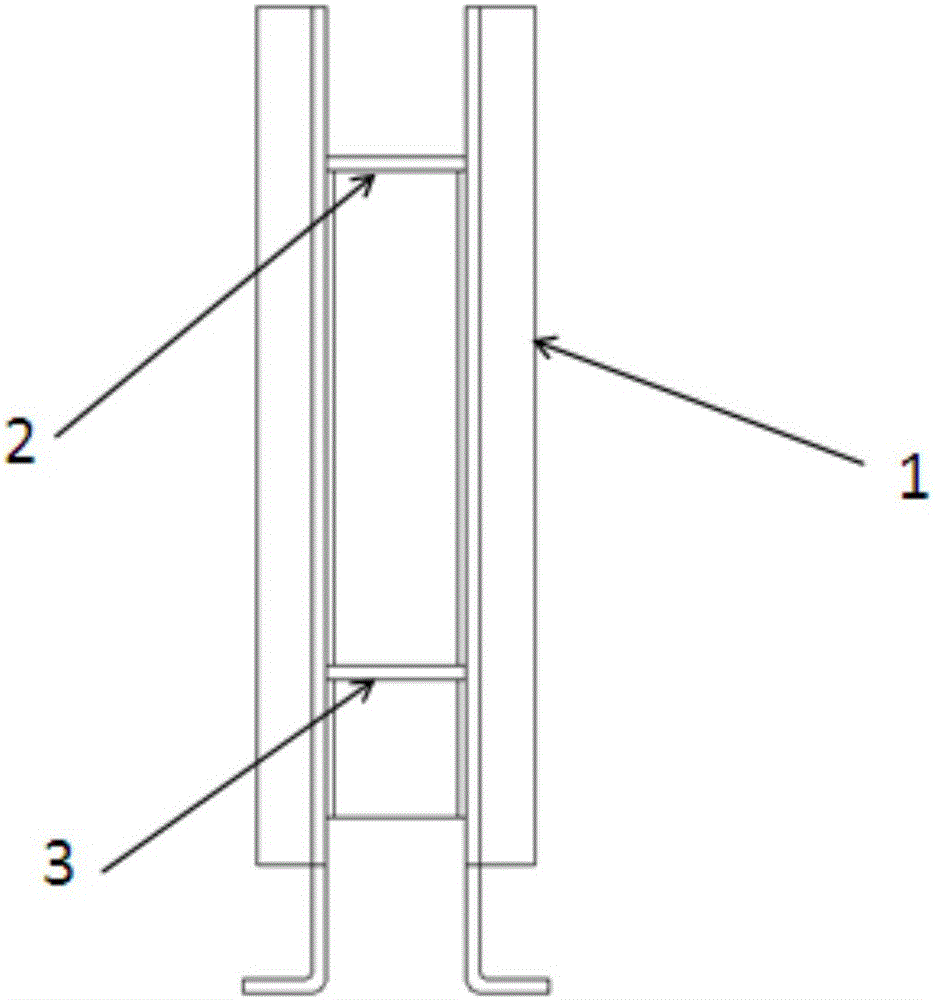

[0017] Please refer to Figure 1 to Figure 4 As shown, the lateral thrust rod fixing device suitable for large moments in the automobile of the present invention includes a bending piece 1, a brace plate 2 and a reinforcing plate 3. The two bent parts are tailor-welded together. The bending part 1 includes two boards 10 and a connecting part 11 arranged front and back. The side and bottom of the board 10 opposite to the connecting part 11 are bent at 90 degrees to form a flange 12. The left and right bending parts 1 Tailor-welded together through the connecting portion 11 . The width of the connecting portion 11 is H, the distance between the upper surface of the connecting portion 11 and the upper surface of the board 10 is D1, and the distance between the lower surface of the connecting portion 11 and the lower surface of the board 10 is D2. The support plate 2 is welded horizontally between the two plate bodies 10, and the distance between the upper surface of the support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com