Adjustable-pressure AGV driving mechanism

A driving mechanism and pressure adjustment technology, which is applied in the direction of motor vehicles, power devices, electric power devices, etc., can solve the problems of spring damping effect failure, cost increase, wheel slipping, etc., to avoid replacement, reduce costs, and ensure stability driving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

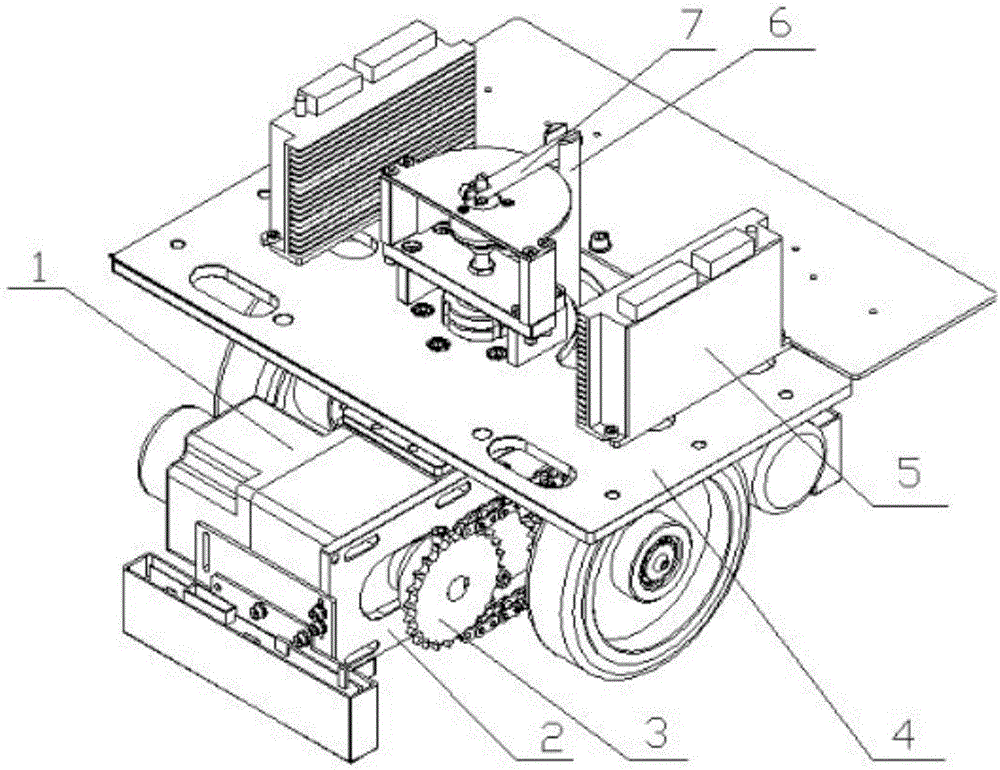

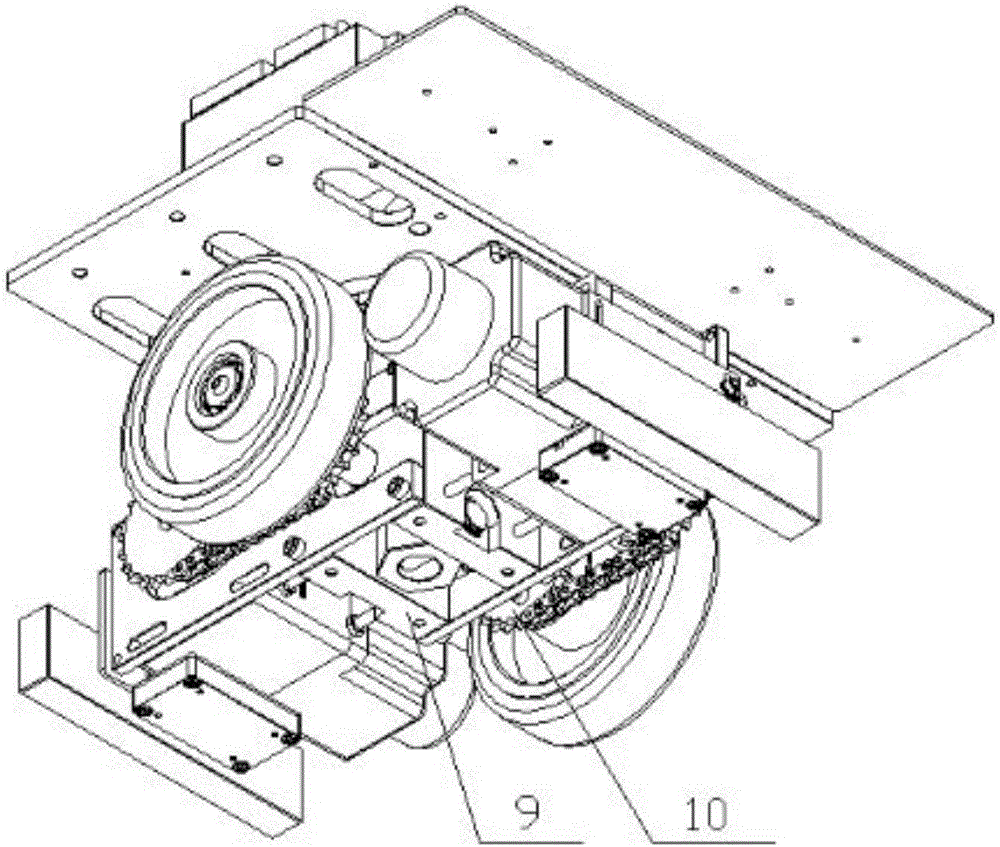

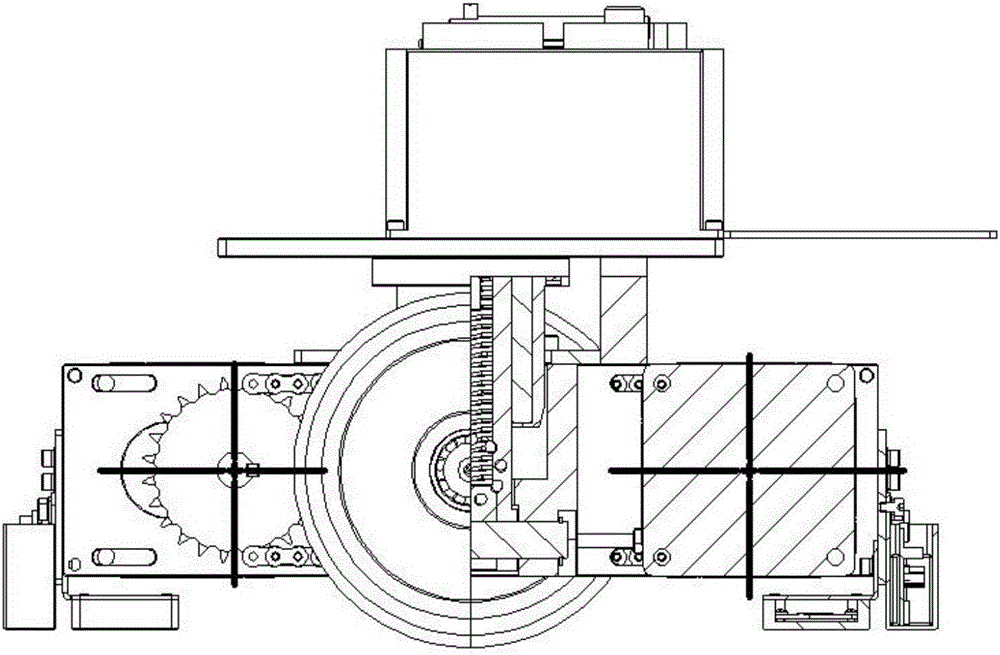

[0018] figure 1 Show the specific embodiment of the present invention: a pressure-adjustable AGV drive mechanism, including a pressure adjustment device and a drive device, the pressure adjustment device includes a bushing 19, a linear bearing 18, a cylinder rod 11, a spring column 13, a spring Pad block 16, spring 17, nut, bolt 22 and support plate frame, wherein axle sleeve 19 is fixed below the support plate 4, cylinder rod 11 is connected together with support base 9 in the support frame by circlip post 13, described The support plate frame includes a support plate 4, a spring adjustment block 6 and a spring adjustment pressure plate 7; the drive device includes a support frame, two motors, two sets of transmission mechanisms, two pairs of wheel bearings, and two drive wheels. The supporting frame includes a fixed base 2, a limiting plate 25, a supporting base 9 and an axle 14, wherein the fixing base 2 is on both sides of the supporting base 9, the limiting plate 25 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com