A single-rotor unmanned helicopter for throwing granules

An unmanned helicopter and single-rotor technology, which is applied to aircraft parts, launching devices, transportation and packaging, etc., can solve the problems of granule splashing, drone crash, and affecting the operation of drones, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

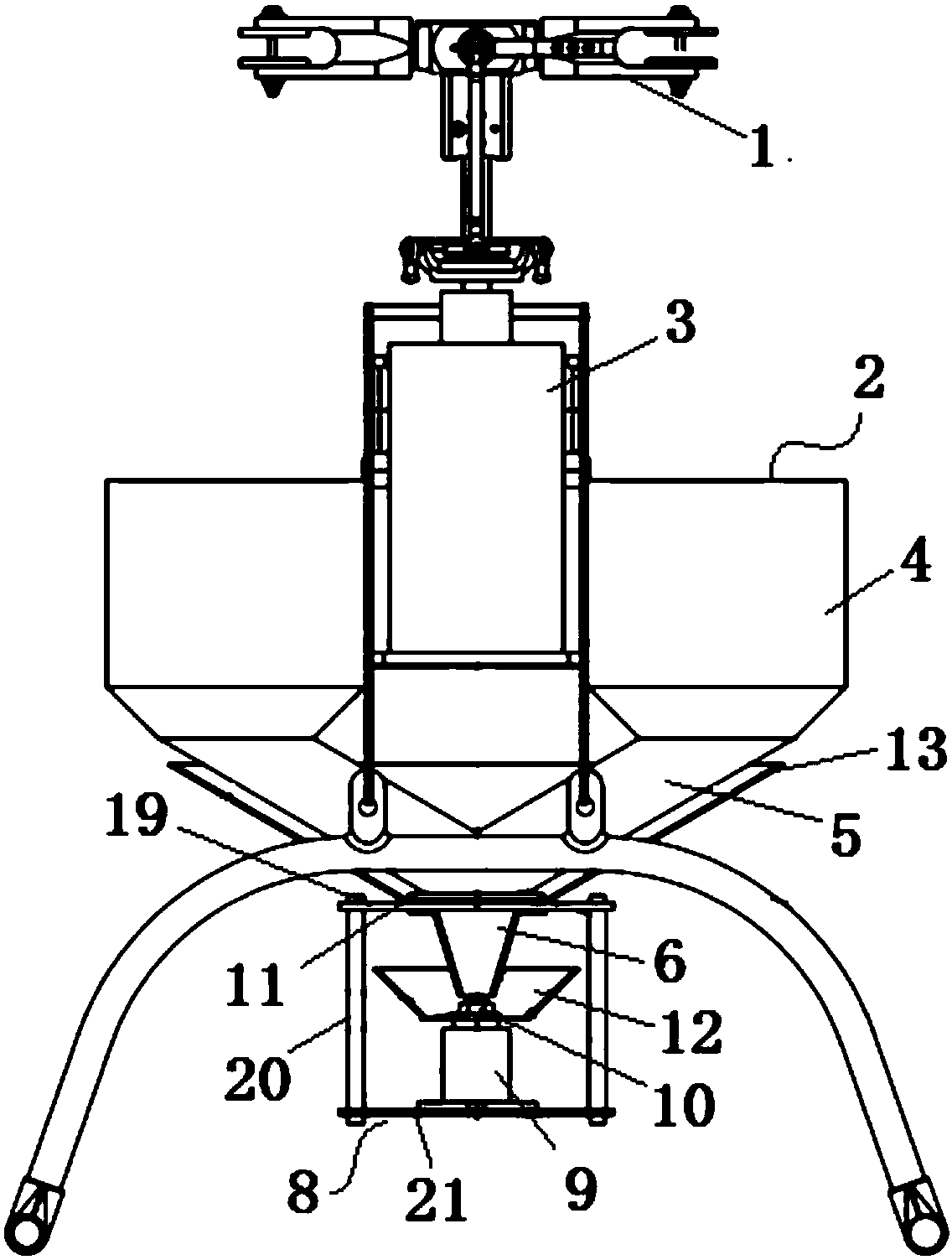

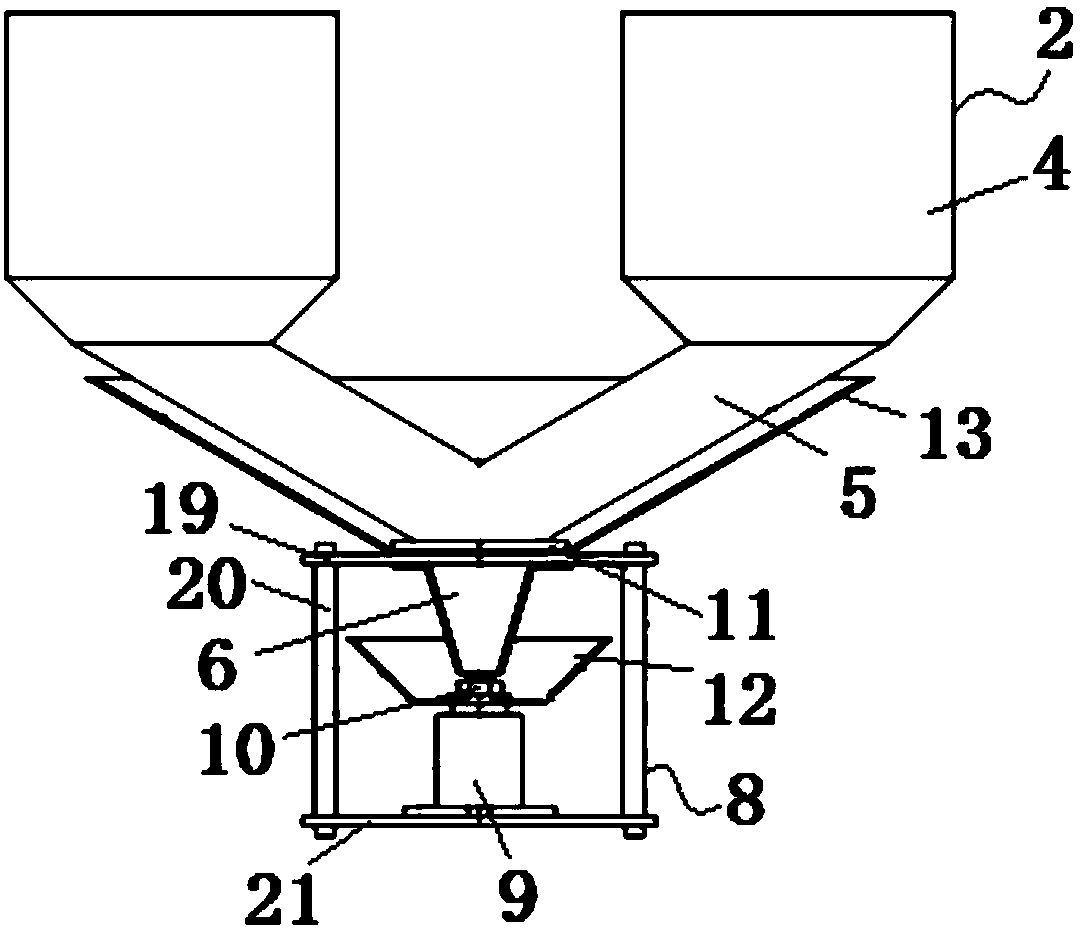

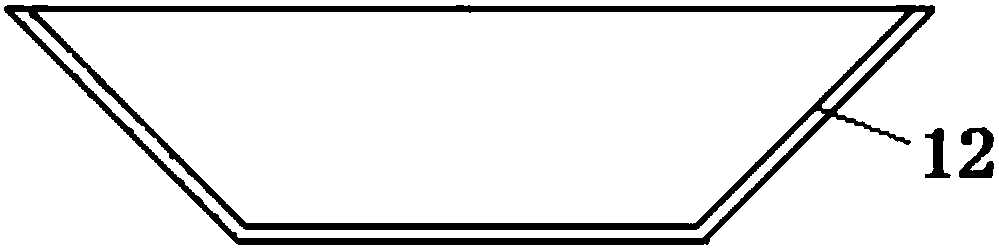

[0024] Such as figure 1 , figure 2 As shown, the present invention includes a throwing device 2 arranged on the single-rotor unmanned helicopter body 1, and the throwing device 2 includes two buckets 4 that are respectively fastened and connected to both sides of the fuselage 3 and open at both ends. The bottom opening of barrel 4 is closed and communicated with by a feed pipe 5 . The middle part of the bottom surface of the feed pipe 5 is provided with a discharge port 11, and the discharge port 11 is tightly connected with an inverted cone-shaped hollow lower feed nozzle 6, which is used to transport the granules in the material barrel 4 to the lower feeder through the feed pipe 5. Nozzle 6. A downwardly extending support 8 is arranged on the feeding pipe 5 outside the feeding nozzle 6, and a motor 9 is arranged on the bracket 8. The output shaft 10 of the motor 9 is arranged vertically upwards and is positioned on the same axis as the center of the feeding nozzle 6. , t...

Embodiment 2

[0033] Such as figure 1 , Figure 5 As shown, the present invention includes a throwing device 2 arranged on the single-rotor unmanned helicopter body 1, and the throwing device 2 includes two barrels 4 that are respectively fastened and connected to both sides of the fuselage 3 and open at both ends. The bottom opening of barrel 4 is closed and communicated with by a feed pipe 5 . The middle part of the bottom surface of the feed pipe 5 is provided with a discharge port 11, and the discharge port 11 is tightly connected with an inverted cone-shaped hollow lower feed nozzle 6, which is used to transport the granules in the material barrel 4 to the lower feeder through the feed pipe 5. Nozzle 6. A downwardly extending bracket 8 is arranged on the feeding pipe 5 outside the feeding nozzle 6, and a motor 9 is arranged on the bracket 8. The output shaft 10 of the motor 9 is arranged vertically upwards and is positioned on the same axis as the center of the feeding nozzle 6. , t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap