Injection mold with cleaning and maintaining device

An injection mold and cleaning technology, which is applied in the field of injection molds with cleaning and maintenance devices, can solve the problems of dust entering, affecting the quality of product production, and dust in products, and achieving the effect of preventing quality reduction and increasing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

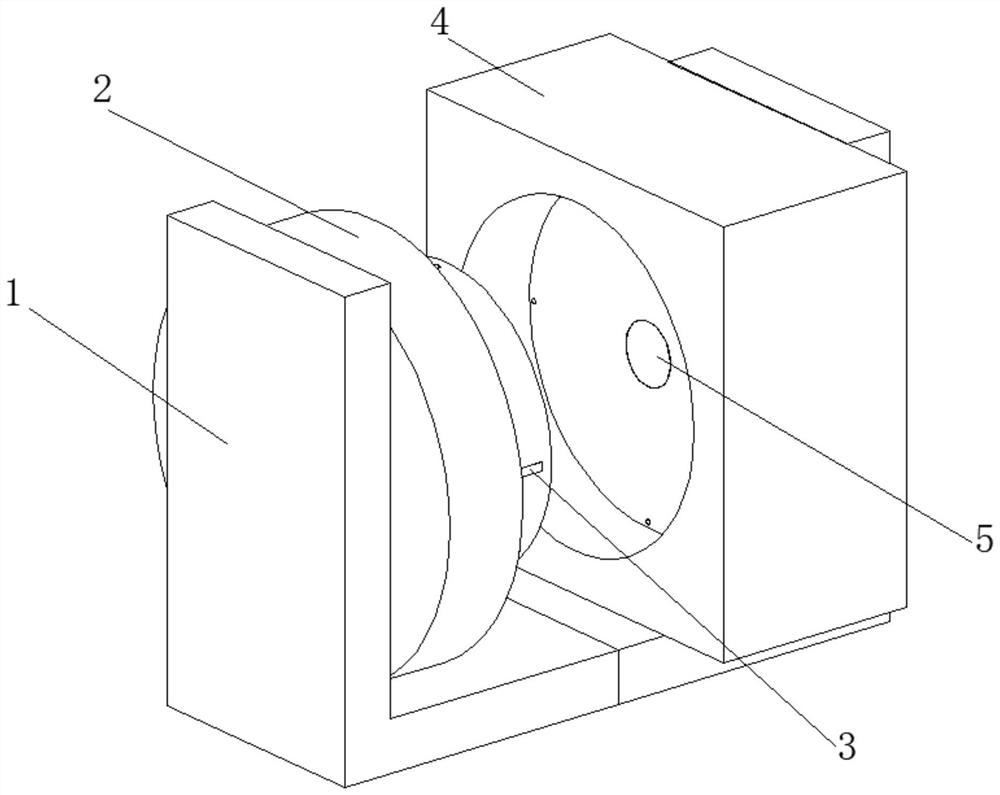

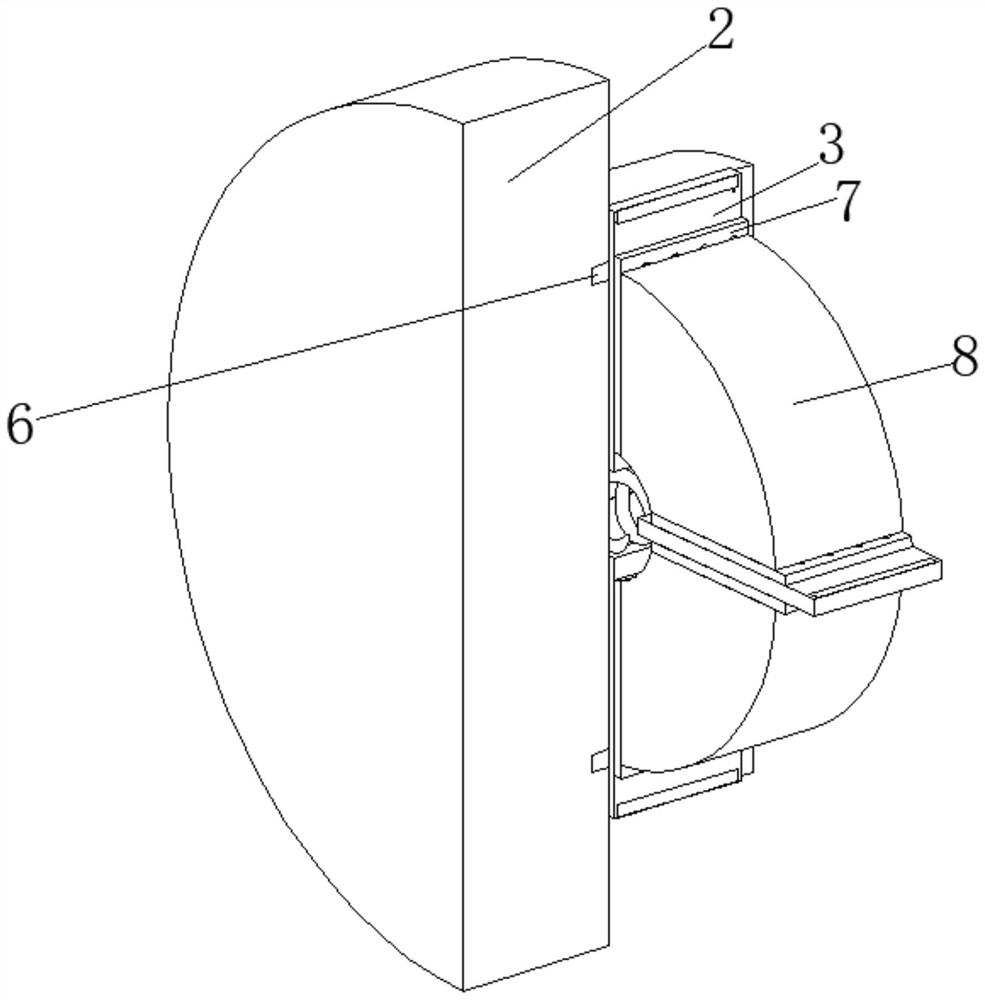

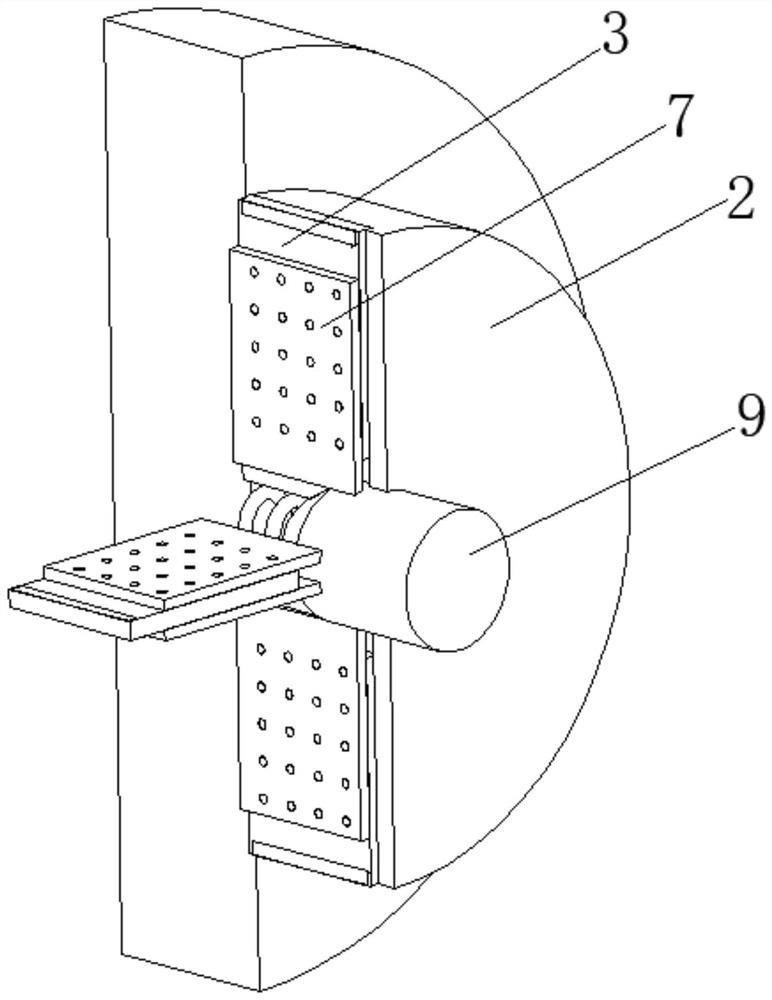

[0031] An injection mold with a cleaning and curing device, such as Figure 1-Figure 8 As shown, including workbench 1, the inner wall of workbench 1 is rotatably connected with upper mold 2, the inner wall of workbench 1 away from upper mold 2 is fixedly connected with lower mold 4, the sliding connection of upper mold 2 is connected with slide plate 3, and the inner wall of upper mold 2 is fixedly connected with lower mold 4. The inner wall is fixedly connected with the filter plate 7 and the sponge 8 respectively, the inner wall of the upper mold 2 is slidably connected with the guide post 9 through the spring, the inner wall of the sliding plate 3 is slidably connected with the inclined plate 32 through the spring, and the inner wall of the sliding plate 3 is movably connected with the rotating plate through the spring 31. When the mold is closed, the guide post 9 in the upper die 2 will be in contact with the moving plate 5 in the lower die 4, and the spring elastic coeffi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap