Discharging mechanism applied to automatic mechanical equipment

A technology of mechanical equipment and feeding mechanism, applied in the direction of solid materials, packaging, packaging items, etc., can solve the problems of uneven quality of storage bags, affecting the quality of discharge, and insufficient discharge structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

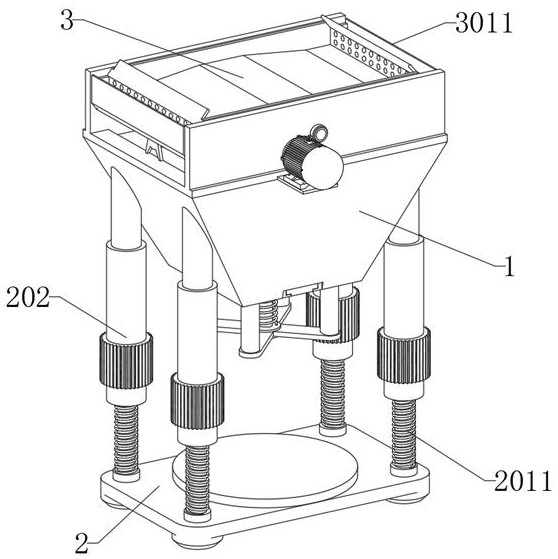

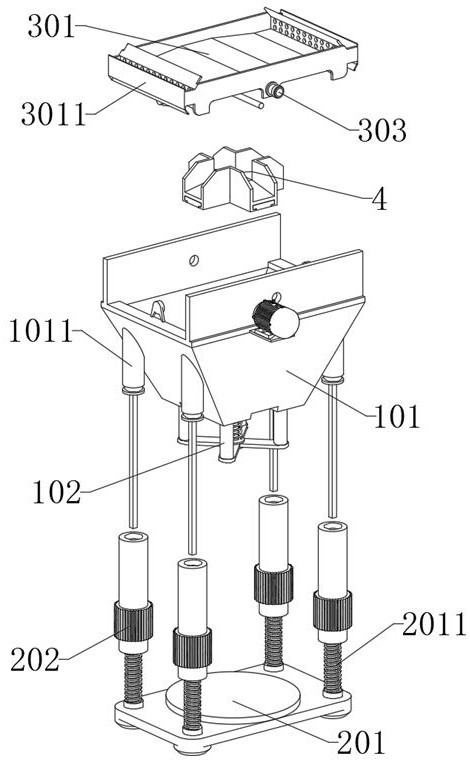

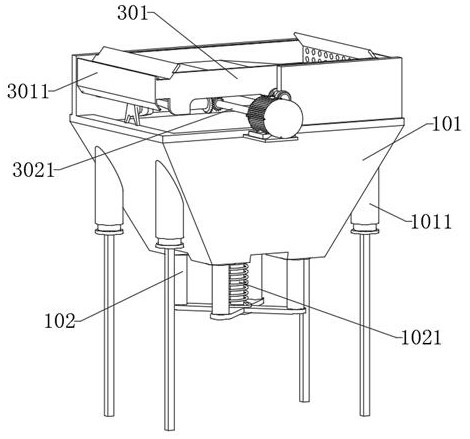

[0069] as attached figure 1 To attach Figure 8 Shown:

[0070] The present invention provides a discharging mechanism applied to automatic mechanical equipment, comprising: a bearing assembly 1; a support part 2 is provided at the lower end of the bearing assembly 1, and the connecting screw 2011 of the support part 2 is inserted into the insertion rod at the bottom of the docking rod 1011, And the insert 2021 is snapped into the slot at the bottom of the outer side of the docking rod 1011; the upper end of the bearing assembly 1 is provided with a feeding mechanism 3, and the installation rod 303 of the feeding mechanism 3 is inserted in the middle position of the upper end of the main body 101, and the trigger lever 302 is rotatably installed on the top of the main body 101 through the connecting block, and the control rod 3021 is connected to the motor at the top front end of the main body 101; the loading assembly 1 is provided with a discharge assembly 4, and the moving...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap