A multi-rotor unmanned helicopter for throwing granules

A multi-rotor unmanned and helicopter technology, used in rotorcraft, unmanned aerial vehicles, motor vehicles, etc., can solve the problems of granule splashing, drone crash, affecting the operation of drones, etc., to avoid leakage or splash, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

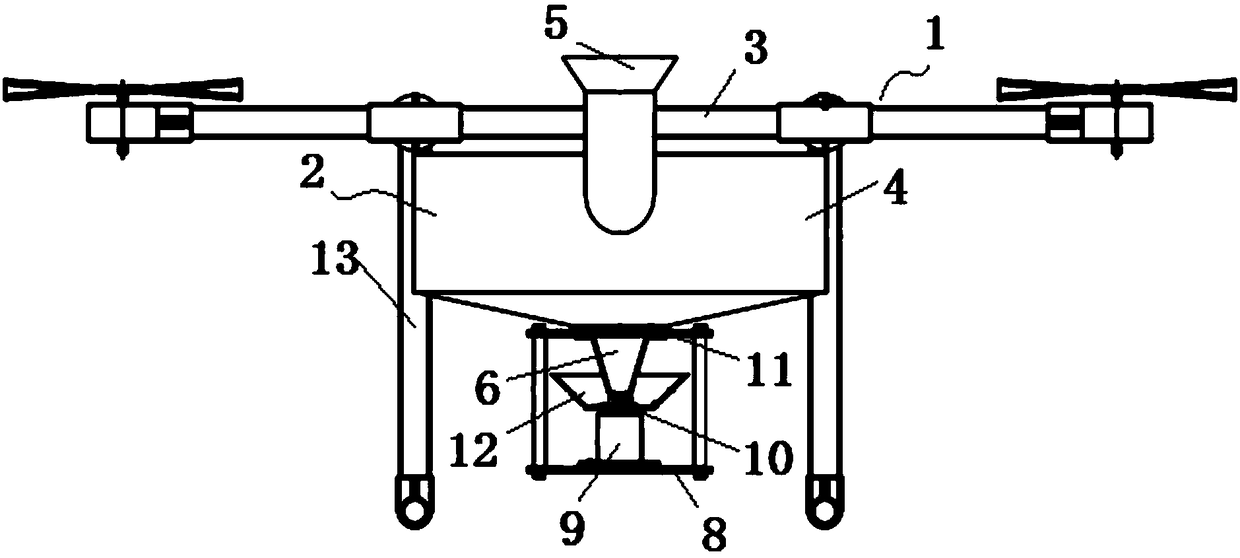

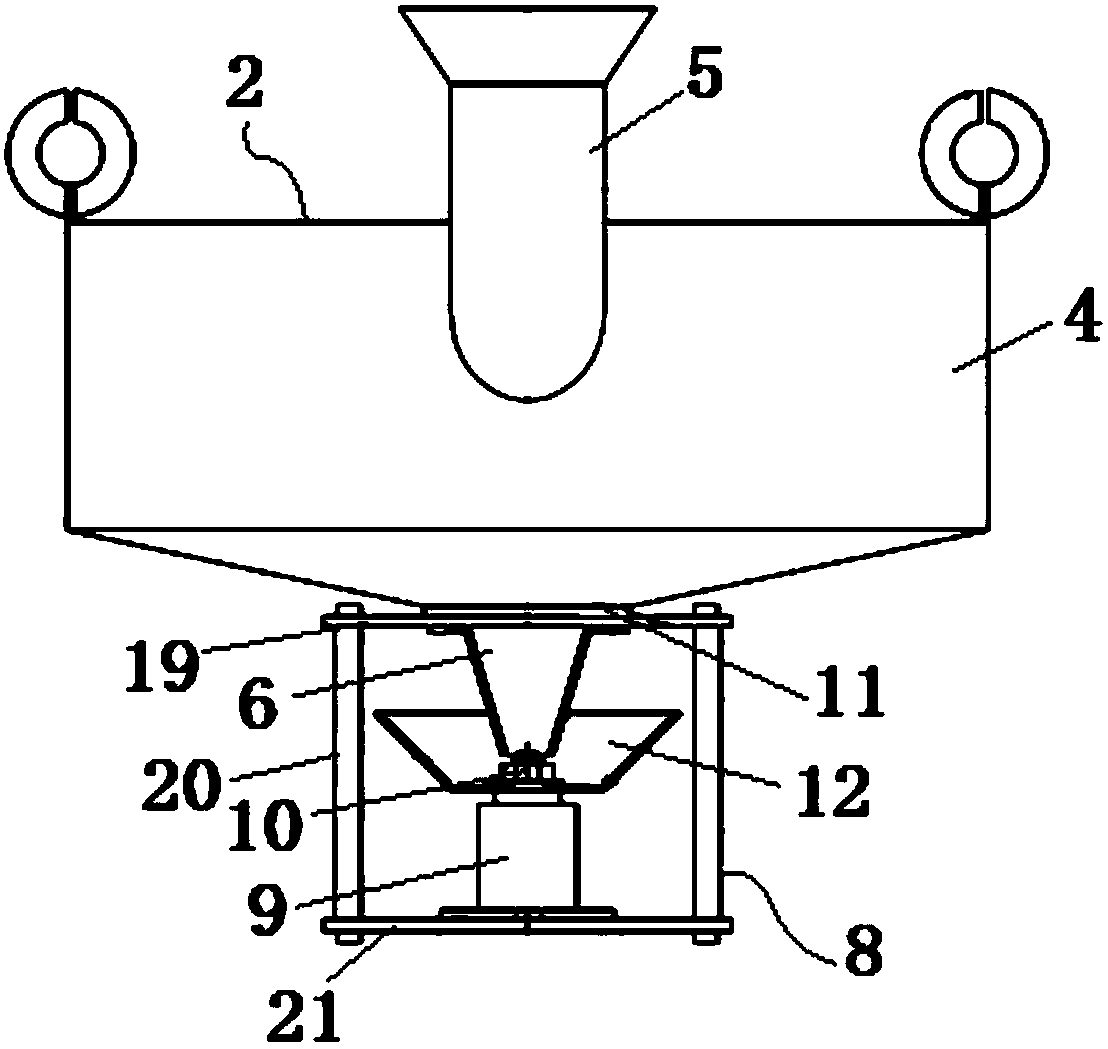

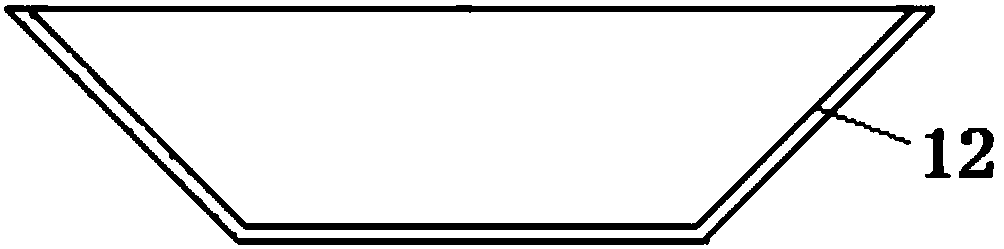

[0023] like figure 1 , figure 2 As shown, the present invention includes a throwing device 2 arranged on the multi-rotor unmanned helicopter body 1, and the throwing device 2 includes a bucket 4 that is tightly connected to the closed ends of the multi-rotor frame 3 directly below the multi-rotor frame 3 by a bracket 13, A feed opening 5 is fastened to the top of the bucket 4, and a discharge opening 11 is provided at the bottom of the bucket 4, and the discharge opening 11 is tightly connected to an inverted cone-shaped hollow blanking nozzle 6 for The granules in the bucket 4 are delivered to the feeding nozzle 6 by the feeding pipe 5 . A downwardly extending support 8 is set on the external barrel 4 of the feeding nozzle 6, and a motor 9 is arranged on the bracket 8. The output shaft 10 of the motor 9 is arranged vertically upwards and is positioned on the same axis as the center of the feeding nozzle 6. , the output shaft 10 is fastened to the center of a turntable 12 f...

Embodiment 2

[0031] like figure 1 , Figure 5 As shown, the present invention includes a throwing device 2 arranged on the multi-rotor unmanned helicopter body 1, and the throwing device 2 includes a bucket 4 that is tightly connected to the closed ends of the multi-rotor frame 3 directly below the multi-rotor frame 3 by a bracket 13, A feed opening 5 is fastened to the top of the bucket 4, and a discharge opening 11 is provided at the bottom of the bucket 4, and the discharge opening 11 is tightly connected to an inverted cone-shaped hollow blanking nozzle 6 for The granules in the bucket 4 are delivered to the feeding nozzle 6 by the feeding pipe 5 . A downwardly extending support 8 is set on the outer barrel 4 of the feeding nozzle 6, and a motor 9 is arranged on the bracket 8. The output shaft 10 of the motor 9 is arranged vertically upwards and is positioned on the same axis as the center of the feeding nozzle 6. , the output shaft 10 is fastened to the center of a turntable 12 for ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap