Die exchange device of mobile phone automated production equipment

A technology of automatic equipment and film device, applied in packaging, packaging machines, transportation and packaging, etc., can solve problems such as reducing switching time, and achieve the effects of reliable circuit connection, fast mold change speed, and reliable gas connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

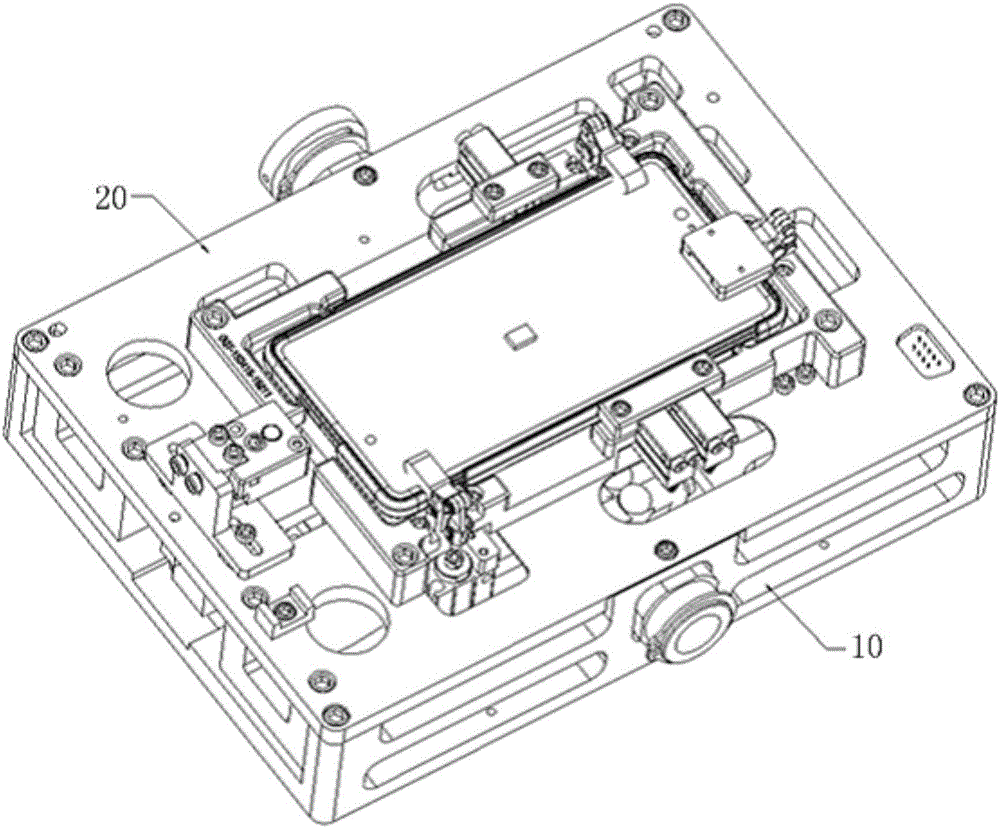

[0011] figure 1 It shows a fast and accurate film changing device based on mobile phone automation equipment provided by the present invention. The film changing device includes a fixing 10, an air circuit device 30 and a product film changing module 20. The air circuit device 30 is located in the In the fixed module 10, the product membrane replacement module 20 is arranged on the fixed module 10, and the product membrane replacement module 20 is fixed on the fixed module 10 by screws.

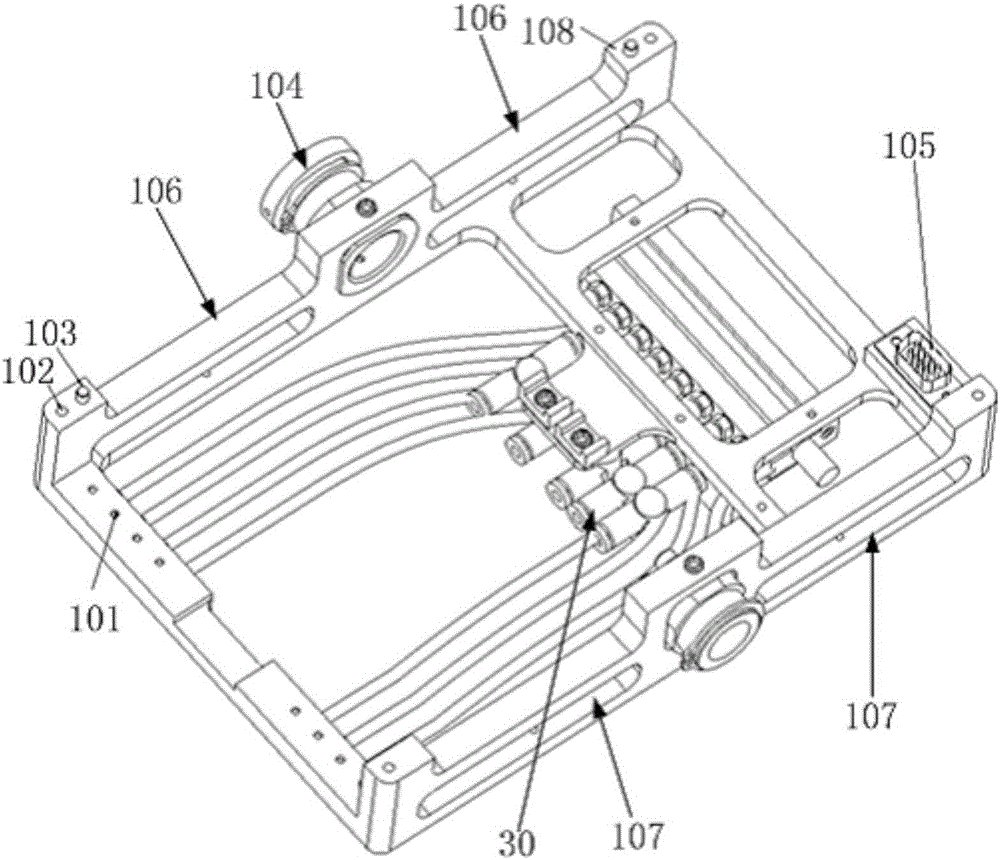

[0012] The fixed module 10 includes a base plate, a first support plate and a second support plate arranged on opposite sides of the base plate, the first support plate is parallel to the second support plate, and multiple an opening, one end side of the second support plate is connected to a boss, the boss is placed on the bottom plate, the boss is perpendicular to the second support plate, and a connector is provided on the boss For the male head 105, a plurality of air passage connection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com