Precision winder for winding yarns

A winder and precise technology, applied in the field of placing equipment, can solve the problems of difficulty in taking out yarn, easy moldy winch, easy wear and damage of wooden winch, etc., to achieve the effect of easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

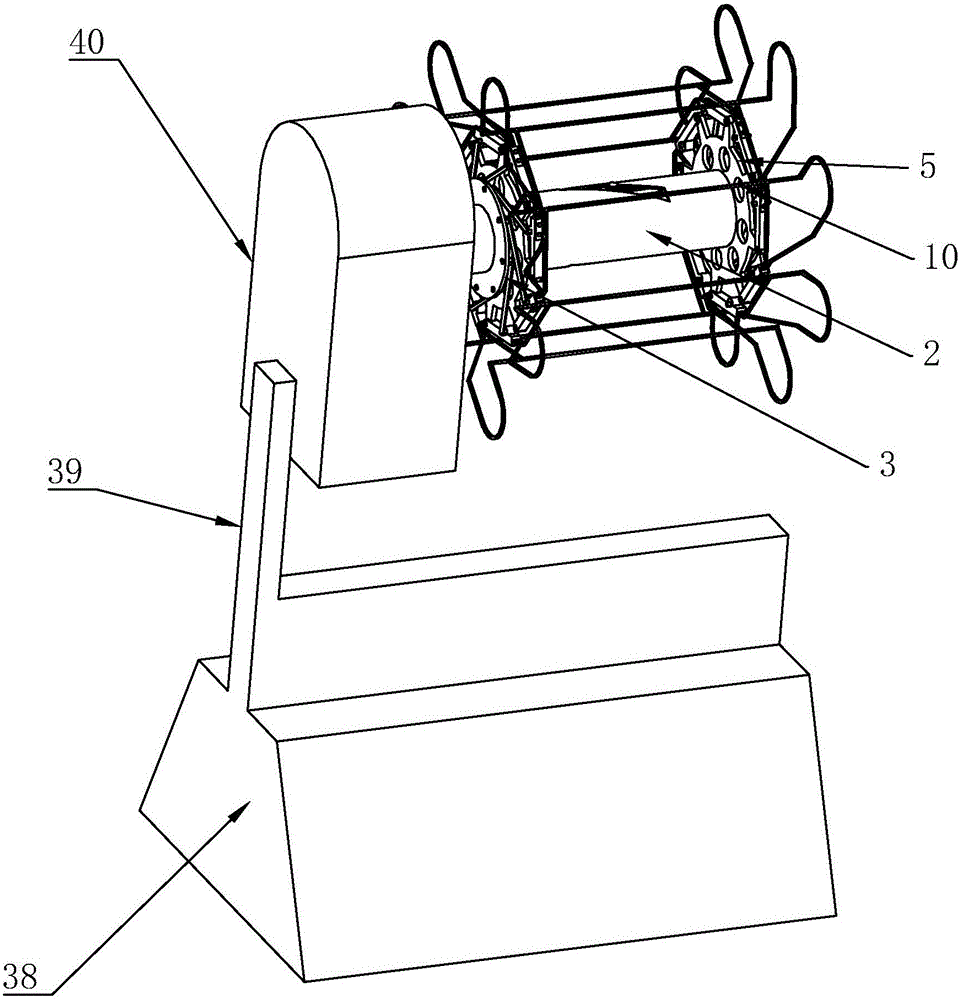

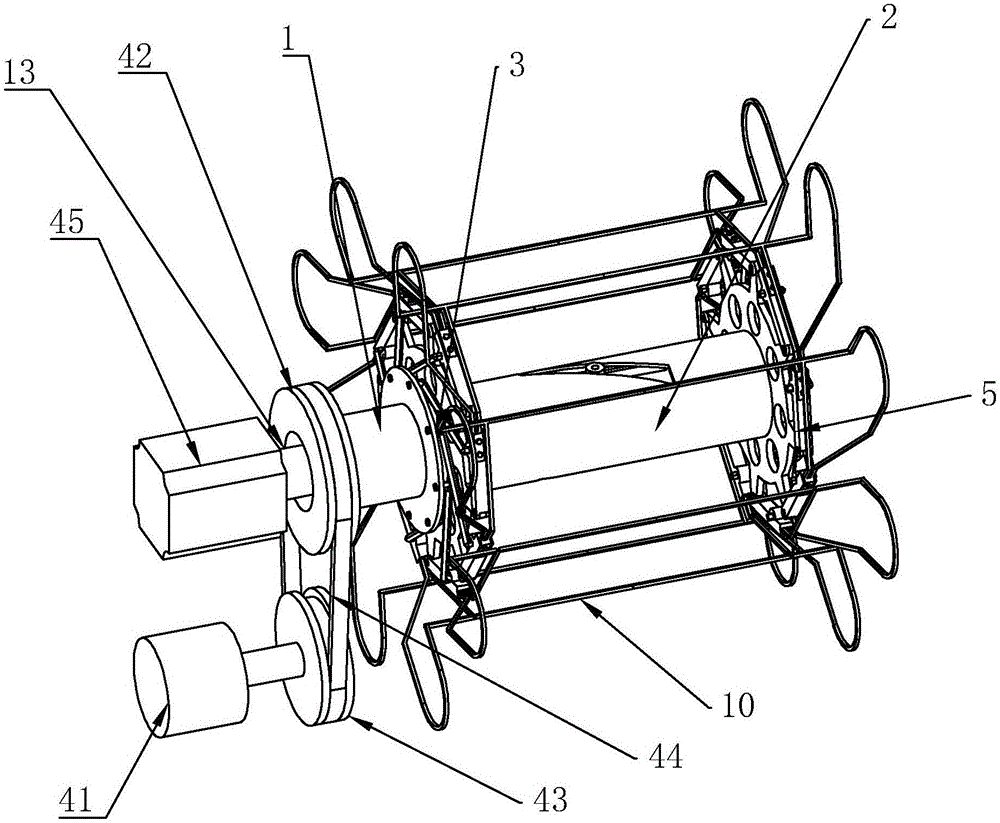

[0051] refer to Figures 1 to 8 As shown, a skein precision winding machine in this embodiment includes a base 38, a support rod 39 is arranged on the base 38, a mounting cover 40 is arranged on the support rod 39, and a mounting cover 40 is arranged inside the mounting cover 40 There is a cylinder 45 and a motor 41. The installation cover 40 is provided with an inner cylinder 1 and an outer cylinder 2 sleeved outside the inner cylinder 1. The inner cylinder 1 passes through the two ends of the outer cylinder 2 and the outer cylinder 2 The end of the cylinder 2 is provided with a first installation ring 3, and the first installation ring 3 is provided with a plurality of first installation holes 4, and the edge of the outer cylinder 2 is provided with a second installation ring 5, and the second installation ring 5 is hinged with a movable block 6, the movable block 6 is provided with a second mounting hole 7, the movable block 6 and the first mounting ring 3 are provided with...

Embodiment 2

[0070] refer to Figures 9 to 14 ,

[0071] On the basis of the first embodiment, the base is further provided with an installation mechanism B0 for installing the winding, and the installation mechanism B0 includes a housing B1.

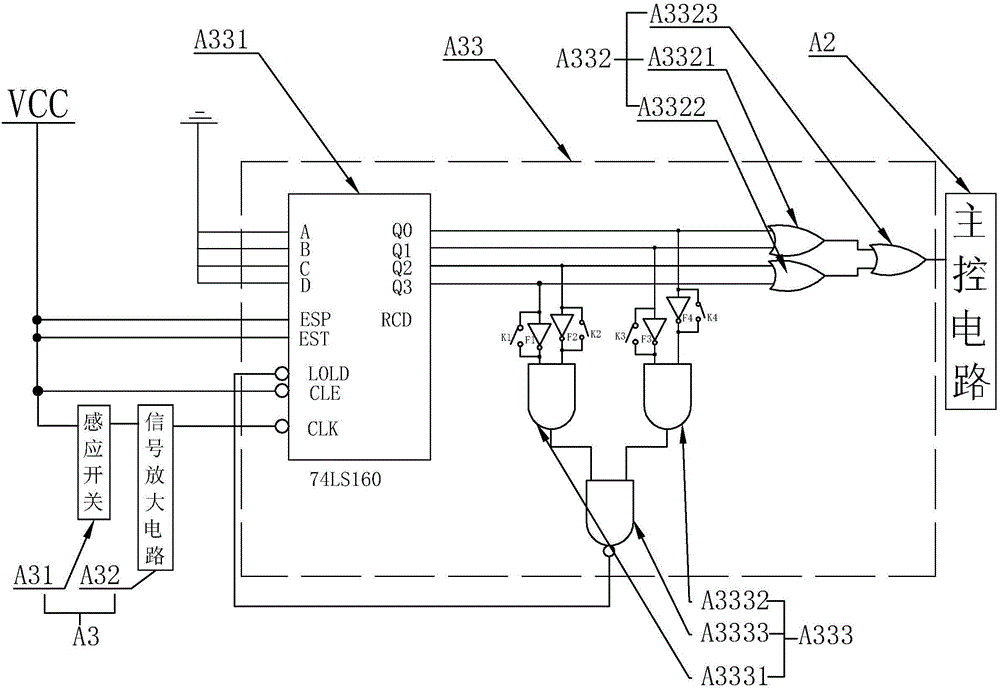

[0072] A control circuit is also provided in the installation mechanism, and the control circuit includes:

[0073] The drive circuit A1 is coupled to the motor to drive the motor to run;

[0074] The main control circuit A2 is coupled to the driving circuit A1 to send a driving signal to the driving circuit A1 to make the driving circuit A1 drive the motor to run, and is also coupled to the external yarn clearer to receive the yarn detection signal sent by the yarn clearer ;

[0075] The detector 3 is set on the winding seat to detect the number of winding replacements, and is also coupled to the main control circuit A2, so as to send the detected winding quantity signal to the main control circuit A2. In the process, firstly, the main control ...

specific Embodiment approach

[0090] As an improved specific implementation, the energy storage circuit A11 includes:

[0091] A diversion diode D, the anode of the diversion diode D is coupled to the motor and grounded;

[0092] A switch tube Q, the switch tube has a first terminal, a second terminal and a control terminal, wherein the control terminal is coupled to the main control circuit A2, the first terminal is coupled to the cathode of the drain diode D, and the second terminal is coupled to the storage The energy capacitor C is coupled between the magnetic switch of the relay K and the motor. The switch tube is a PMOS tube. When the motor stops, the internal coil of the motor will release electric energy, and the switch tube Q is turned on, and the electric energy will be drained Under the action of the diode D, it flows through the switching tube Q into the energy storage capacitor C, and is stored by the energy storage capacitor C. When it needs to be restarted, the energy storage capacitor C wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com