Electric double-speed winch and work method thereof

A two-speed, capstan technology, applied in hoisting devices, spring mechanisms, etc., can solve problems such as inconvenient speed regulation and complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

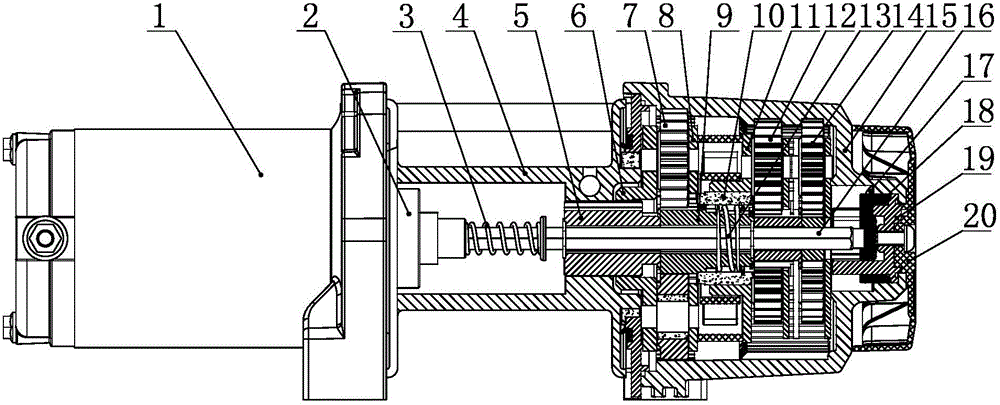

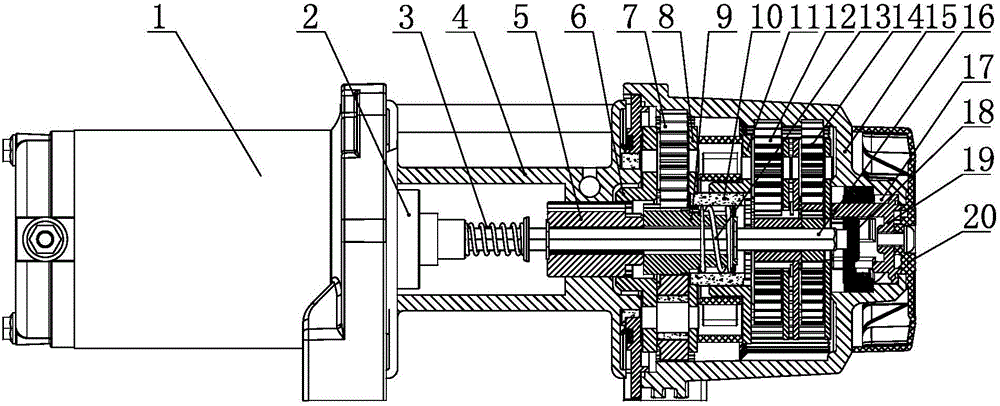

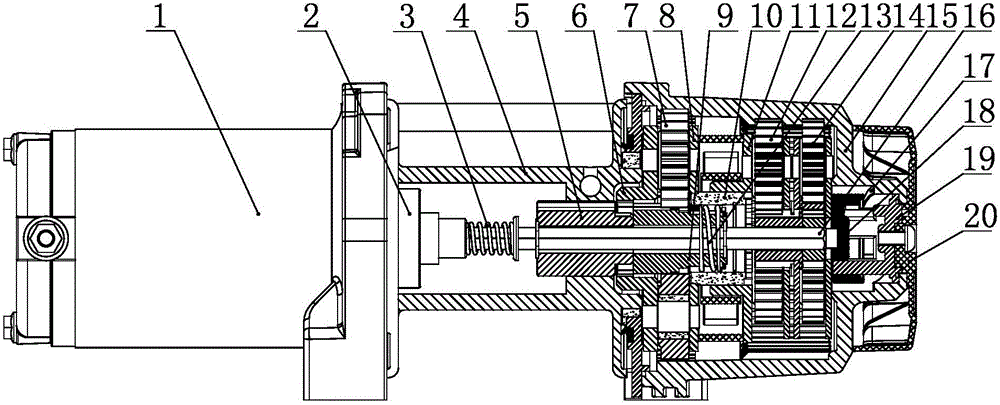

[0017] Now in conjunction with accompanying drawing, the present invention will be further described.

[0018] Such as Figure 1-4 As shown, the electric two-speed winch includes a winch support, a motor 1, a transmission shaft 16, a winch 4, a reduction transmission box 15, and a station control mechanism. There are 14 first-stage planetary gear sets, 12 second-stage planetary gear assemblies, and 3-stage planetary gear assemblies 7 in the reduction transmission box. The motor is connected to one end of the transmission shaft through the backstop clutch 2, and the other end of the transmission shaft is connected to the drive shaft through the primary center wheel. The first-stage planetary gear assembly, the first-stage planetary gear assembly, the second-stage planetary gear assembly, and the third-stage planetary gear assembly are sequentially connected to form a reduction transmission, in which the first-stage planetary gear assembly and the second-stage planetary gear ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com