Industrial synthesis method of tris(butoxyethyl)phosphate and device thereof

A synthesis method, the technology of phosphoric acid three, applied in the direction of phosphorus organic compounds, chemical instruments and methods, compounds of group 5/15 elements of the periodic table, etc., can solve the problems of environmental pollution, product yield reduction, etc., and achieve the reduction of by-products , the amount of lye is reduced, and the production process conditions are easy to control

Active Publication Date: 2016-10-12

ZHEJIANG WANSHENG

View PDF5 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] 2) The process yield of products on the existing market is generally 87-89%, and about 10% of the organic by-products f

Method used

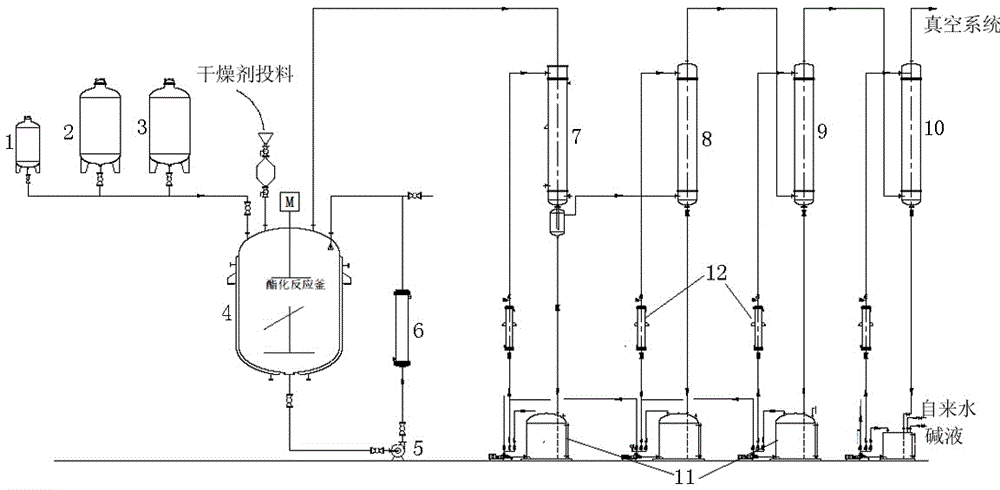

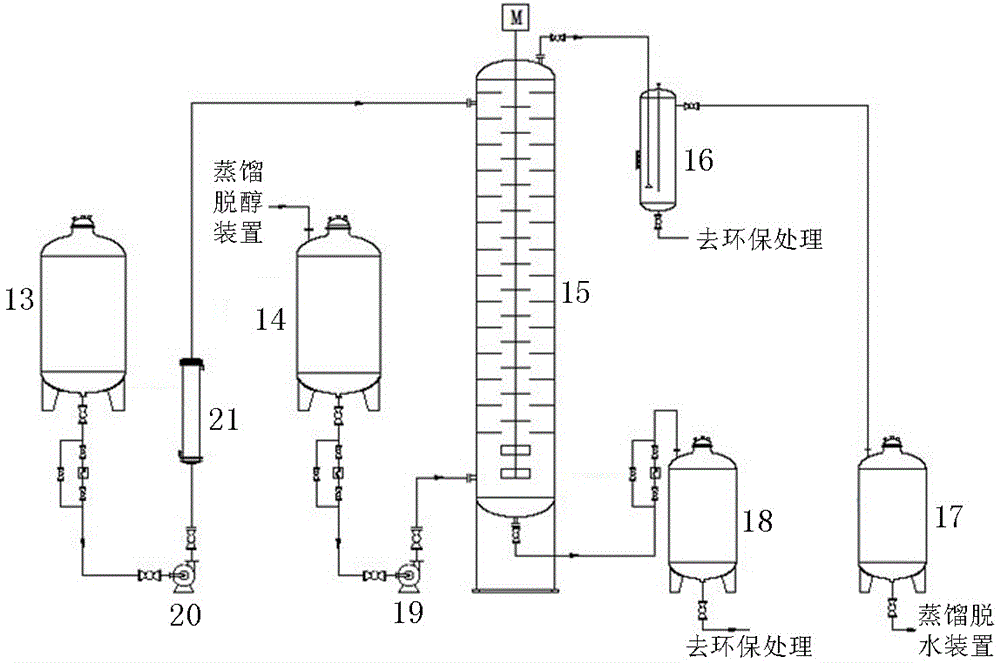

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to view more

Login to view more PUM

Login to view more

Login to view more Abstract

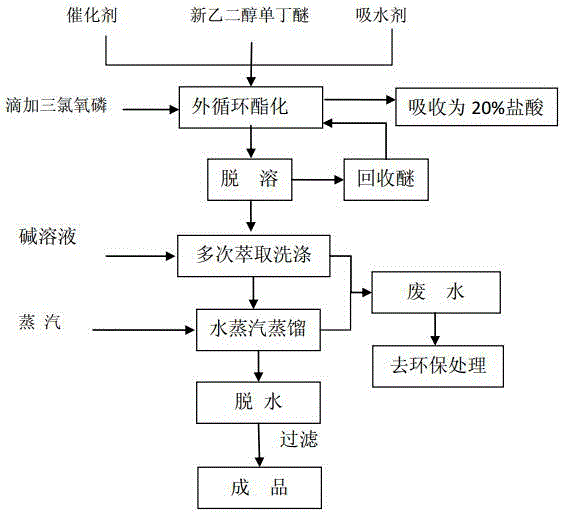

The invention relates to an industrial synthesis method of tris(butoxyethyl)phosphate (TBEP) and a device thereof. Specifically, the method consists of: in the presence of a water absorbent and a catalyst, reacting ethylene glycol monobutyl ether with phosphorus oxychloride to generate a TBEP crude product, letting the TBEP crude product enter a washing tower to conduct multistage countercurrent extraction washing, then bringing the crude product into a stratification pot to conduct standing stratification, removing a saponification and aqueous layer from an upper material layer, then subjecting the obtained material layer to a distillation kettle, carrying out reduced pressure water vapor dealcoholization, introducing water vapor to the kettle bottom, conducting water vapor distillation for 0.9-1.2h, removing residual ethylene glycol monobutyl ether, and then carrying out reduced pressure dehydration and filtering to obtain a TBEP finished product. The product obtained by the method has low sodium ion content, and the tris(butoxyethyl)phosphate purity is high, the method reduces the probability of tris(butoxyethyl)phosphate degradation or loss, improves the yield, also reduces the environmental pressure, and can lower the content of sodium ions in the product without harsh distillation conditions, thereby greatly reducing the production cost, improving product quality, and increasing the economic benefits of enterprises.

Description

technical field [0001] The invention belongs to the technical field of chemical synthesis, and in particular relates to an industrial synthesis method of tri(butoxyethyl) phosphate and a device thereof. Background technique [0002] Tris(butoxyethyl)phosphate (abbreviated as TBEP) is a flame retardant plasticizer, which is a colorless and transparent liquid with the molecular formula C 18 h 39 PO 7 , it is mainly used for flame retardancy and plasticization of polyurethane resin rubber, cellulose, polyvinyl alcohol, etc., and its molecular structure is: [0003] . [0004] The current synthesis methods are mainly: ① acid-binding method, FMC’s patents US3020303 and EP0091426 describe the production process of tris (alkoxyalkyl) phosphate, the production process adopts the reaction of alkoxy alkyl alcohol and alkali metal oxide, And through the dehydration reaction, the alkali metal alkoxide is reacted with phosphorus oxychloride to generate the product of tri(alkoxyalky...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): C07F9/08

CPCC07F9/091

Inventor 吕云兴陶光撑金译平王轶

Owner ZHEJIANG WANSHENG

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap