Optimized control system for coal gas flow of blast-furnace hot blast stove

A technology of gas flow and hot blast stove, which is applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems such as reducing the cost of blast furnace ironmaking, unreasonable gas distribution of hot blast stoves, etc., and achieve stable air supply temperature and hot blast stove operation , good working condition change, reasonable combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

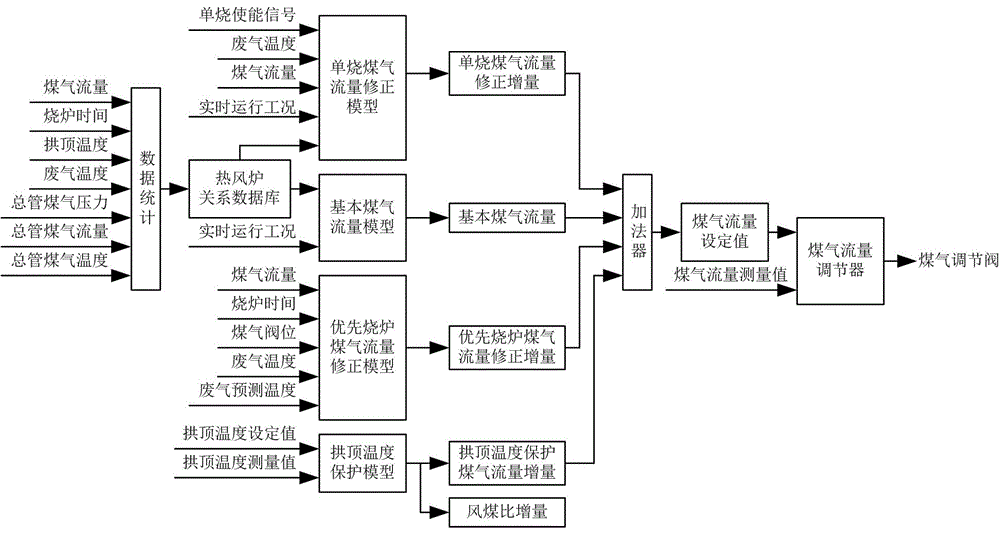

[0022] Basic Gas Flow Model

[0023] According to the current main pipe gas pressure, main pipe gas flow and main pipe gas temperature, find no more than three optimal working condition knowledge items satisfying the correlation of the above three parameters higher than 0.95 from the hot stove relational database, and weight them to obtain the current basic gas flow.

[0024] Vault temperature protection model

[0025] The dome temperature is obtained through the predictive control algorithm and the predicted dome temperature T_YC after N minutes is obtained. The dome predicted temperature T_YC and the dome temperature set value T_SD output the air-to-coal ratio increment E_FMB and the gas flow increment E_JBMQL through the fuzzy control algorithm. The fuzzy control algorithm rule is

[0026] If T_YC-T_SD>E_L and IF T_YC-T_SD

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com