A comprehensive utilization device for hydrometallurgy

A technology of hydrometallurgy and dosing equipment, applied in the direction of diaphragm, electrolysis process, electrolysis components, etc., can solve the problems of excessive consumption of raw materials, generation of acidic waste liquid, pollution, etc., to achieve waste reduction, safe production process, no second The effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

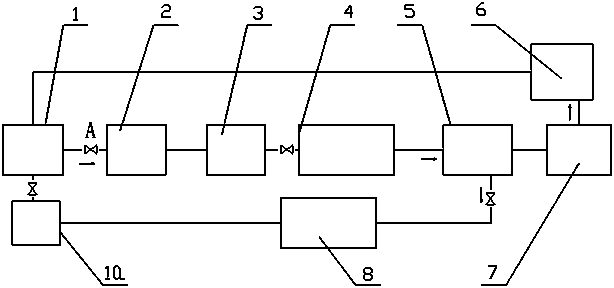

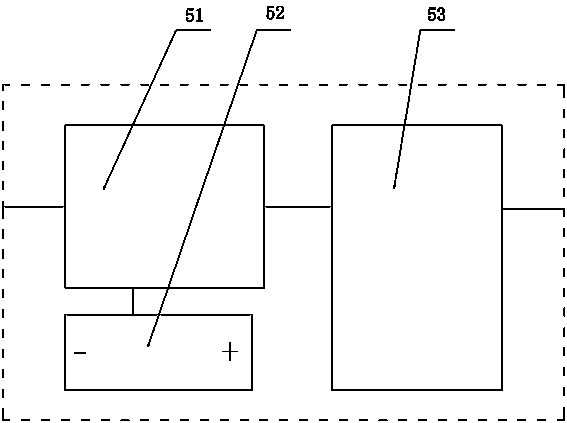

[0018] Such as figure 1 As shown, a hydrometallurgical comprehensive utilization device includes a reaction tank 1, a filter 2, a liquid storage tank 3, a metal extraction device 4, a membrane separation device 5, a water recycler 6, an electrowinning system 7, a concentration device 8 and The dosing device 1a, the reaction tank 1, the filter 2, the liquid storage tank 3, the metal extraction device 4, the membrane separation device 5 and the electrowinning system 7 are connected with pipelines in sequence according to the liquid flow direction, and the electrowinning system 7 is recycled with water through the pipelines The water recovery device 6 is connected to the reaction tank 1 through the return pipe, the reaction tank 1 is equipped with a dosing device 1a, and the dos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com