MOCVD system and reaction gas conveying device thereof

A technology of reactive gas and conveying device, which is applied in directions from chemical reactive gas, crystal growth, gaseous chemical plating, etc., can solve the problems of increasing the cost of substrate epitaxy, increasing the consumption of reactive gas, etc., and achieves low cost and easy manufacturing. Processing, high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

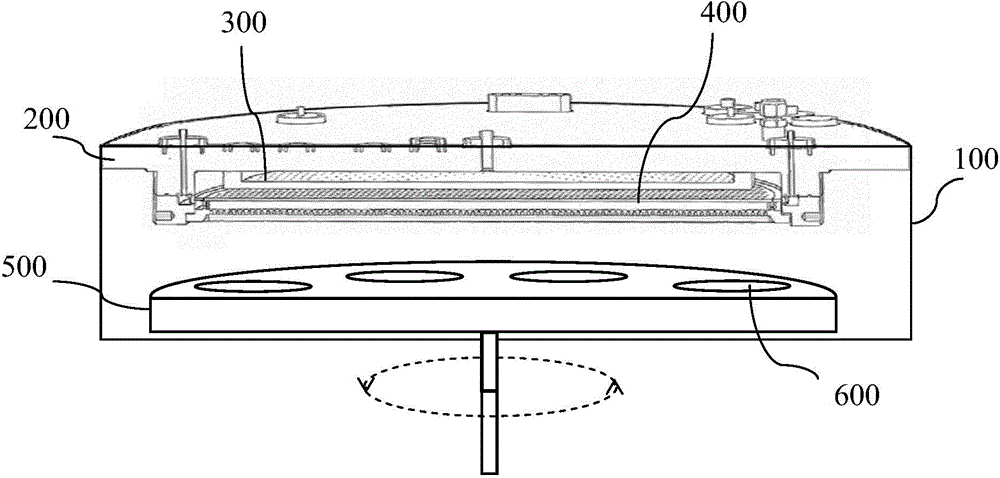

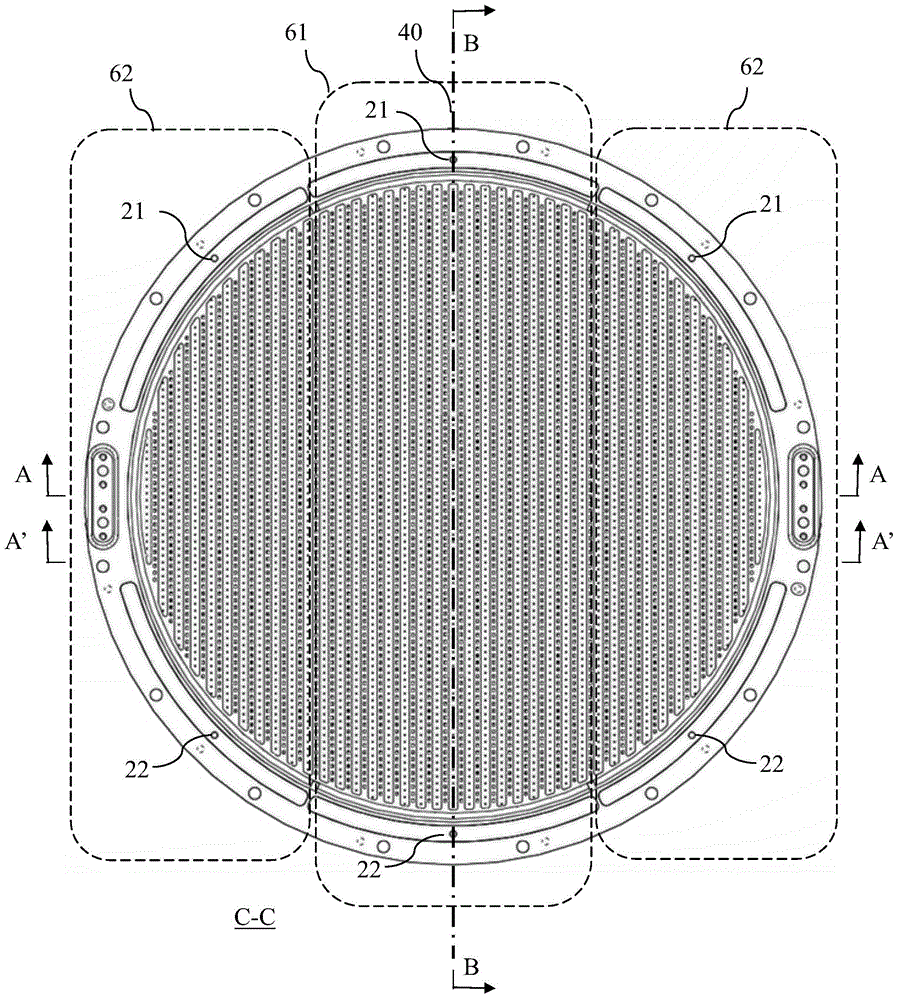

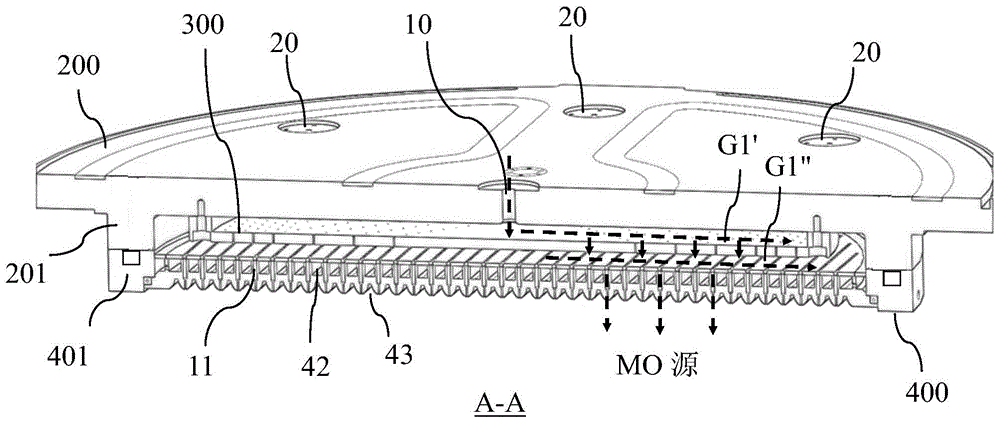

[0047] An embodiment of the present invention provides a reaction gas delivery device for an MOCVD system, which is used for reaction gas delivery and uniform distribution control. Such as figure 1 As shown, the MOCVD system includes a reaction chamber 100, a chamber cover 200 located at the top of the reaction chamber 100, a reaction gas delivery device located below the chamber cover 200, and an epitaxial wafer 600 located below the reaction gas delivery device in the reaction chamber 100. (or substrate) tray 500. Other equipment such as the heater of the tray 500, the central shaft supporting and driving the tray 500 to rotate, etc., can be equipped according to actual application conditions, and will not be listed here. The reaction gas conveying device in this embodiment is used to introduce at least two routes of reaction gases required for epi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com