Expanding concrete tubular pile as well as expanding device and expanding method

A technology of concrete pipe piles and construction methods, applied in the direction of sheet pile walls, buildings, foundation structure engineering, etc., can solve the problems of loss of frictional resistance, no substantial progress, little effect, etc., to achieve improved bearing capacity, simple structure, and easy construction convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The invention will be further described below in conjunction with the accompanying drawings.

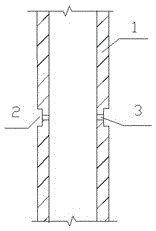

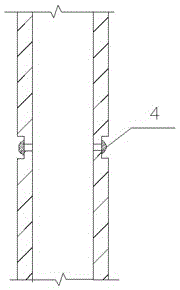

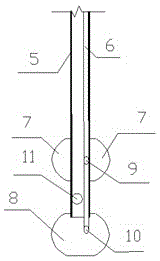

[0025] like Figure 1-8 As shown, the expanded diameter concrete pipe pile disclosed by the present invention, the expanded diameter device and the expanded diameter method are composed of a concrete pipe pile 1, an embedding belt 2, a small round hole 3, a check valve 4, a grouting pipe 5, a pressure air pipe 6, a rubber Air upper cavity 7, rubber air lower cavity 8, rubber air upper cavity air hole 9, rubber air rubber air lower cavity air hole 10, slurry hole 11, concrete pipe pile diameter expansion ring belt 12, check valve end 41, rubber Pad 42, guide bar 43, tension spring 44, rectangular section ring 45, pole 46, elastic barb 47, connecting rod 48, spring hanging ring 49 form. Each section of the concrete pipe pile 1 is provided with at least one embedding belt 2, and at least two equidistant small round holes 3 are arranged on the pile pipe within the scope of each e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com