Pile board wall and its construction method

A construction method and pile-slab wall technology, applied in excavation, foundation structure engineering, construction, etc., can solve problems such as poor aesthetics, difficulty in planting grass and greening, and poor landscape effects, so as to save steel, avoid abruptness and bluntness, and reduce engineering costs. volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

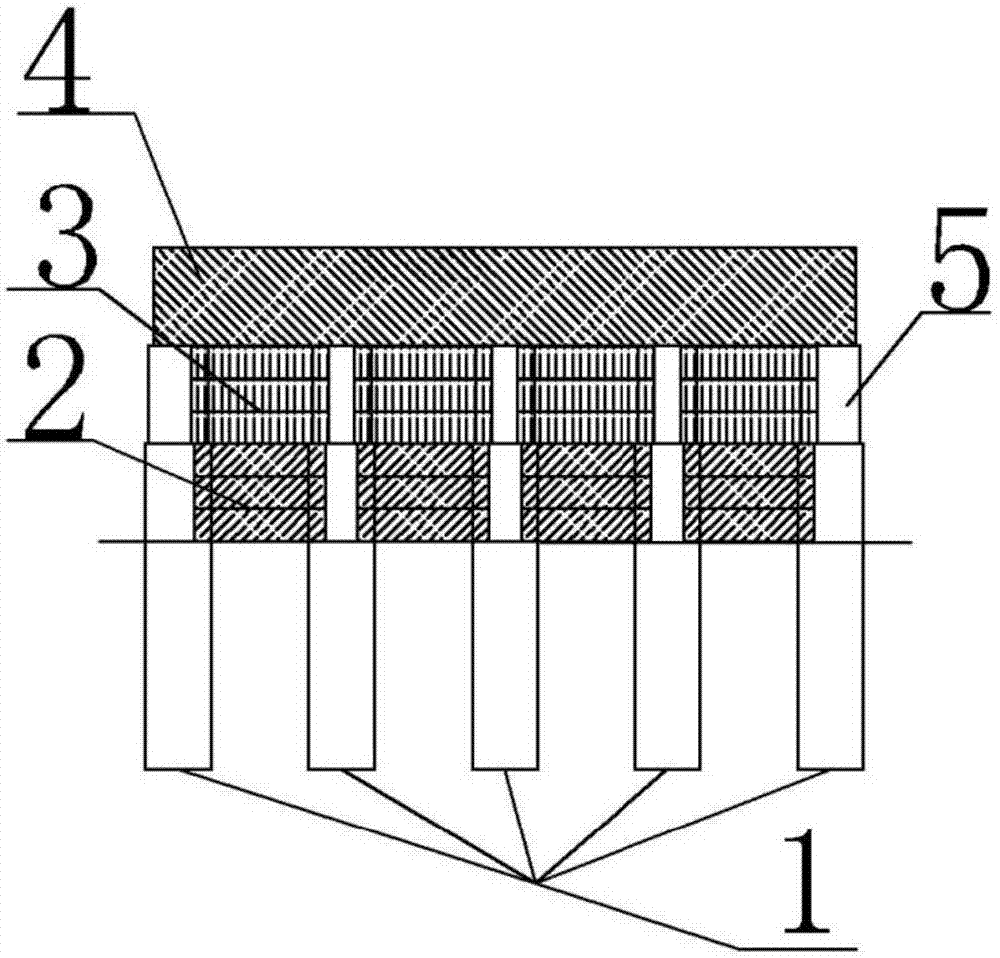

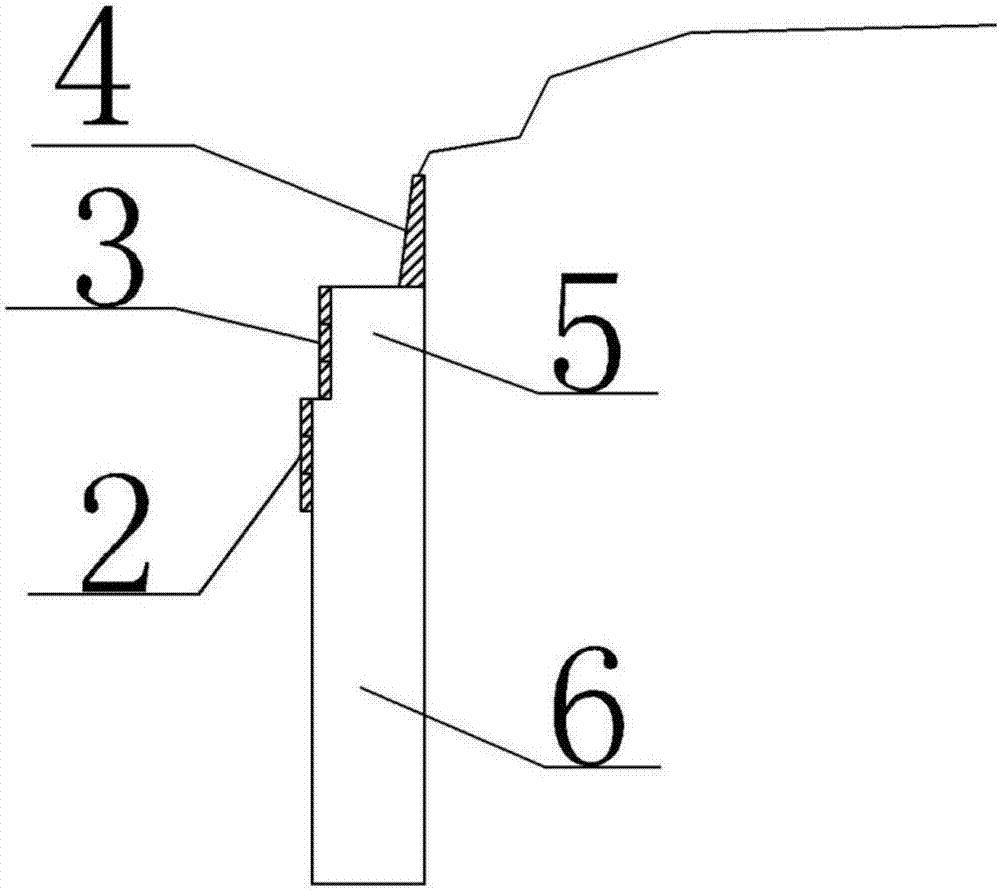

[0031] Such as figure 1 with figure 2 As shown, a pile-slab wall includes a retaining wall, more than one variable cross-section anti-slide pile 1, more than one first retaining plate 2 and more than one second retaining plate 3; The sliding pile 1 includes an anti-slide pile base 6 and one or more anti-slide pile cantilevers 5 with similar shapes and different cross-sectional areas; the cross-sectional area of the anti-slide pile base 6 is larger than the cross-sectional area of the anti-slide pile cantilever 5; The anti-slide pile base 6 and one or more anti-slide pile cantilevers 5 are connected in order from large to small in cross-sectional area; the anti-slide pile base 6 of two adjacent variable cross-section anti-slide piles 1 passes through the A retaining plate 2 is connected to each other; the anti-slide pile cantilevers 5 of two adjacent variable cross-section anti-slide piles 1 are connected to each other through a second retaining plate 3; one side of the ret...

Embodiment 2

[0045] Such as figure 1 with figure 2 The construction method of the pile-slab wall includes the following steps:

[0046] A. Dig pile holes and make variable cross-section anti-slide piles 1 respectively;

[0047] a. Digging pile holes;

[0048] b. Making variable cross-section anti-slide pile 1:

[0049] 1) According to the shape and size of the anti-slide pile base 6, the steel bars are tied and the concrete is poured. After the concrete is solidified, the anti-slide pile base 6 is obtained;

[0050] The size of the pile hole is greater than or equal to the cross section of the anti-slide pile base 6 of the variable cross-section anti-slide pile 1;

[0051] Preferably, the size of the pile hole is larger than the cross section of the anti-slide pile base 6; the steel bars are placed in the pile hole for binding, and concrete is poured upward from the bottom of the steel bars.

[0052] The size of the pile hole is determined according to the size of the cross section of the anti-slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com