Large-span heavy-load force-induced backfill open-hole lining structure

A heavy-load, large-span technology, used in wellbore lining, tunnel lining, shaft equipment, etc., can solve the problems of waste of masonry work and the inability to guarantee the durability of lining in open holes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

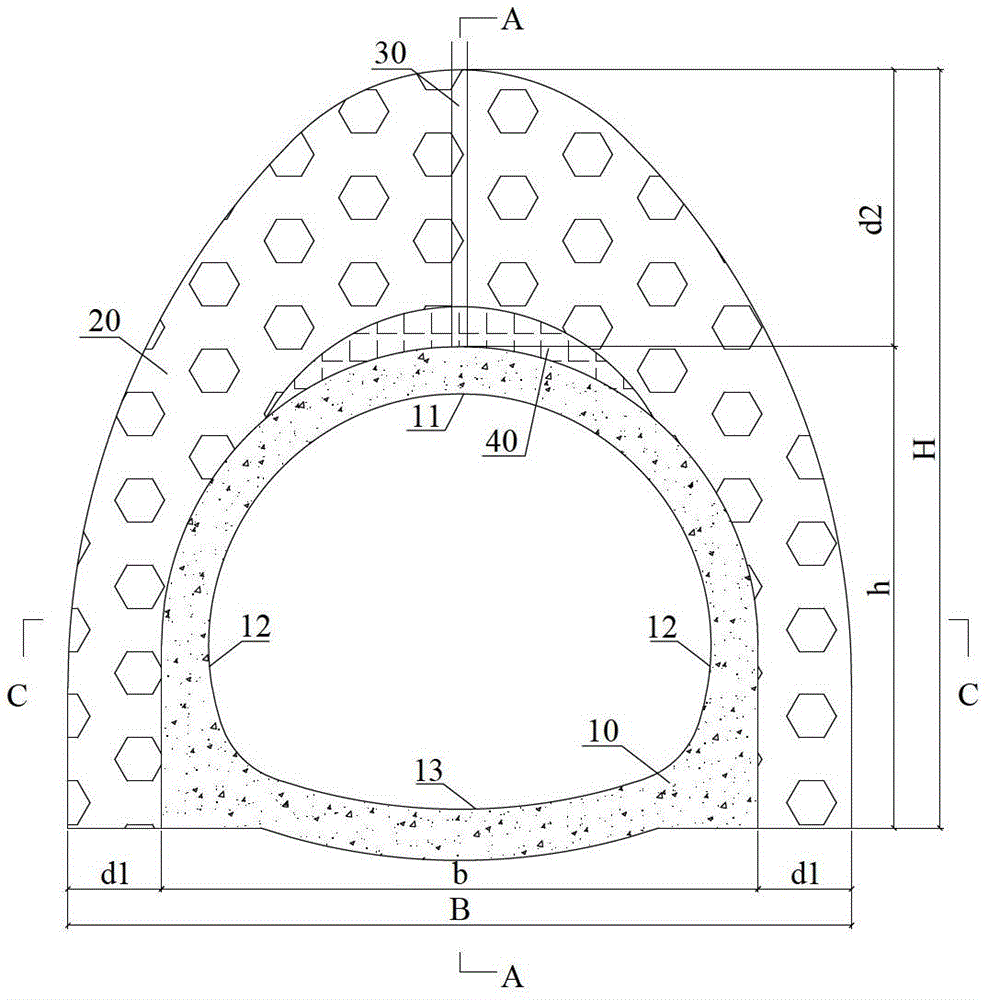

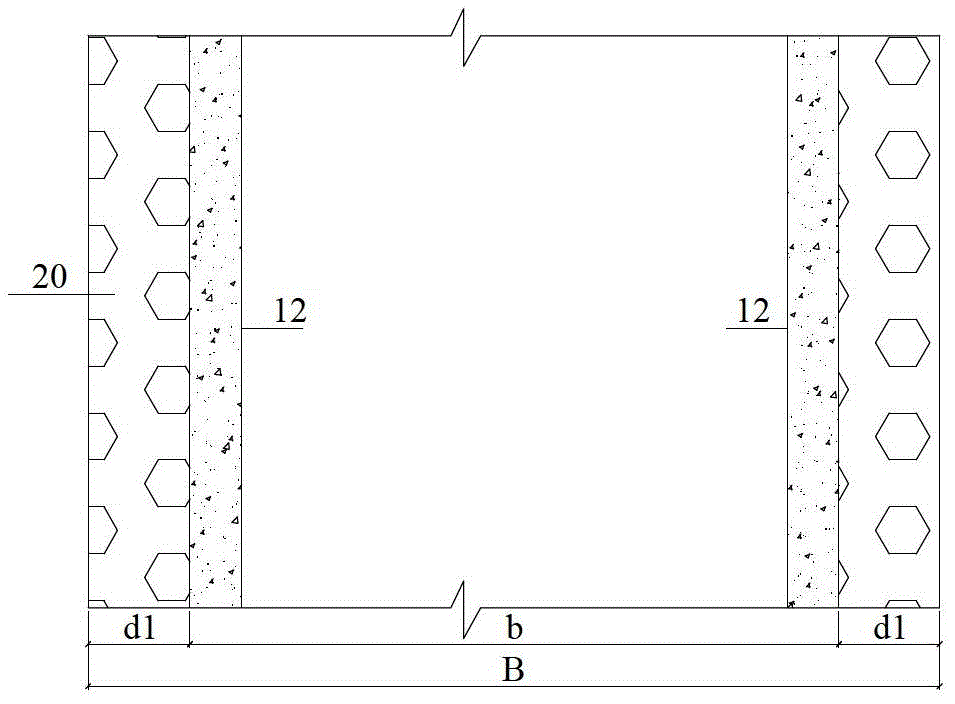

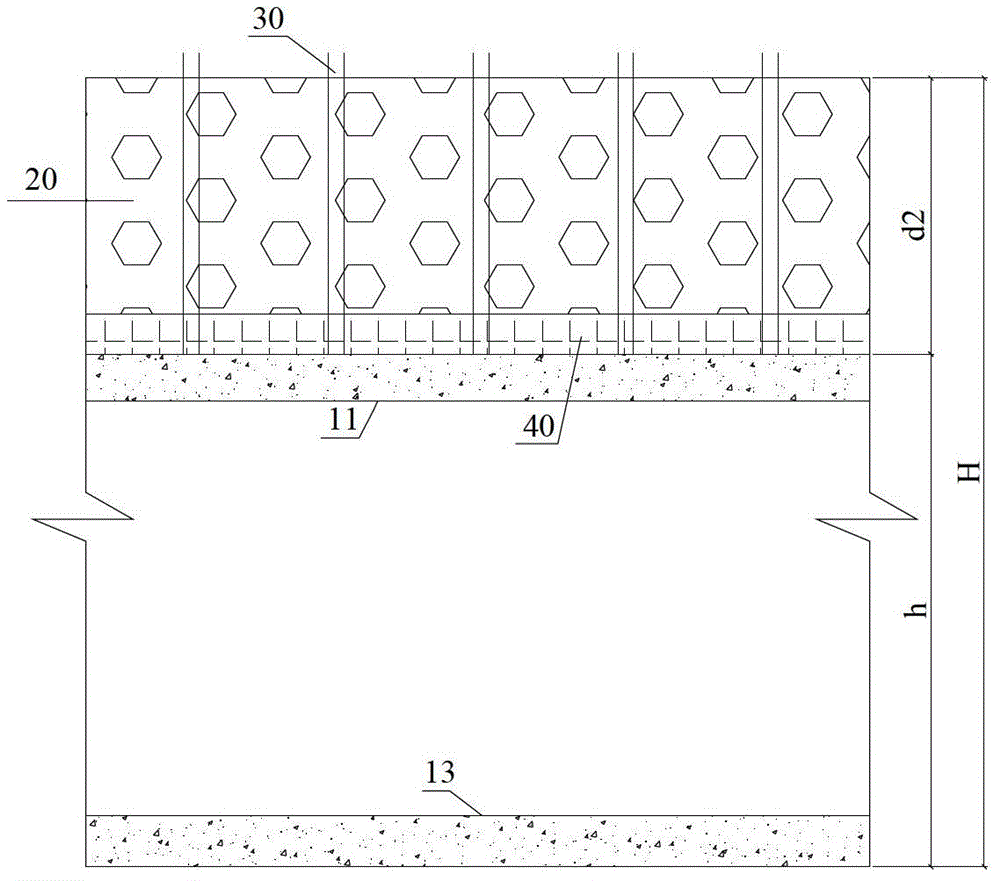

[0016] refer to figure 1 , figure 2 and image 3 , the large-span heavy-load force-induced backfill open-hole lining structure of the present invention, the open-hole lining 10 with an annular cross-section is formed by the arch part 11, the side wall 12 and the inverted arch 13 molded by concrete or reinforced concrete, and the open-hole lining 10 The outer contour arc surface of the arch portion 11 and the side wall 12 is provided with a force-induced protective arch 20 . The open tunnel lining 10 is the main load-bearing structure, and the force-induced protective arch 20 mainly redistributes the external force on the open tunnel lining 10, and also bears part of the backfill load. The layered composite support structure can effectively support the open-cut large-span tunnel space, and only by adjusting the structural shape and material character...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com