Integral anti-slip design method for wing-wall tunnel doors

A design method and anti-slip technology, applied in tunnels, tunnel linings, mining equipment, etc., can solve problems such as not adapting to technology and social and economic development, poor social and economic benefits, and high door safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0090] refer to Figure 7 , the overall anti-slip design method of the wing wall type tunnel door of the present invention comprises the following steps:

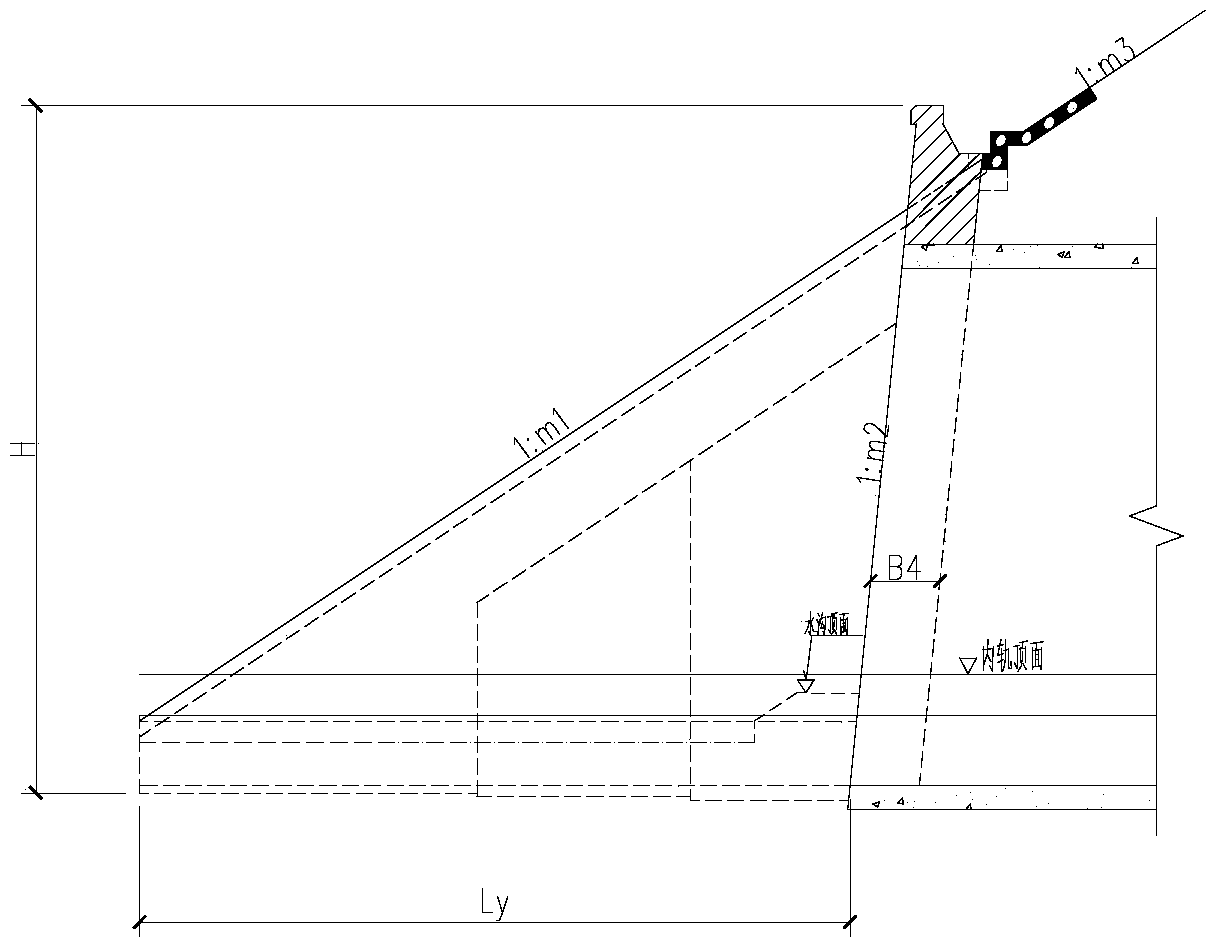

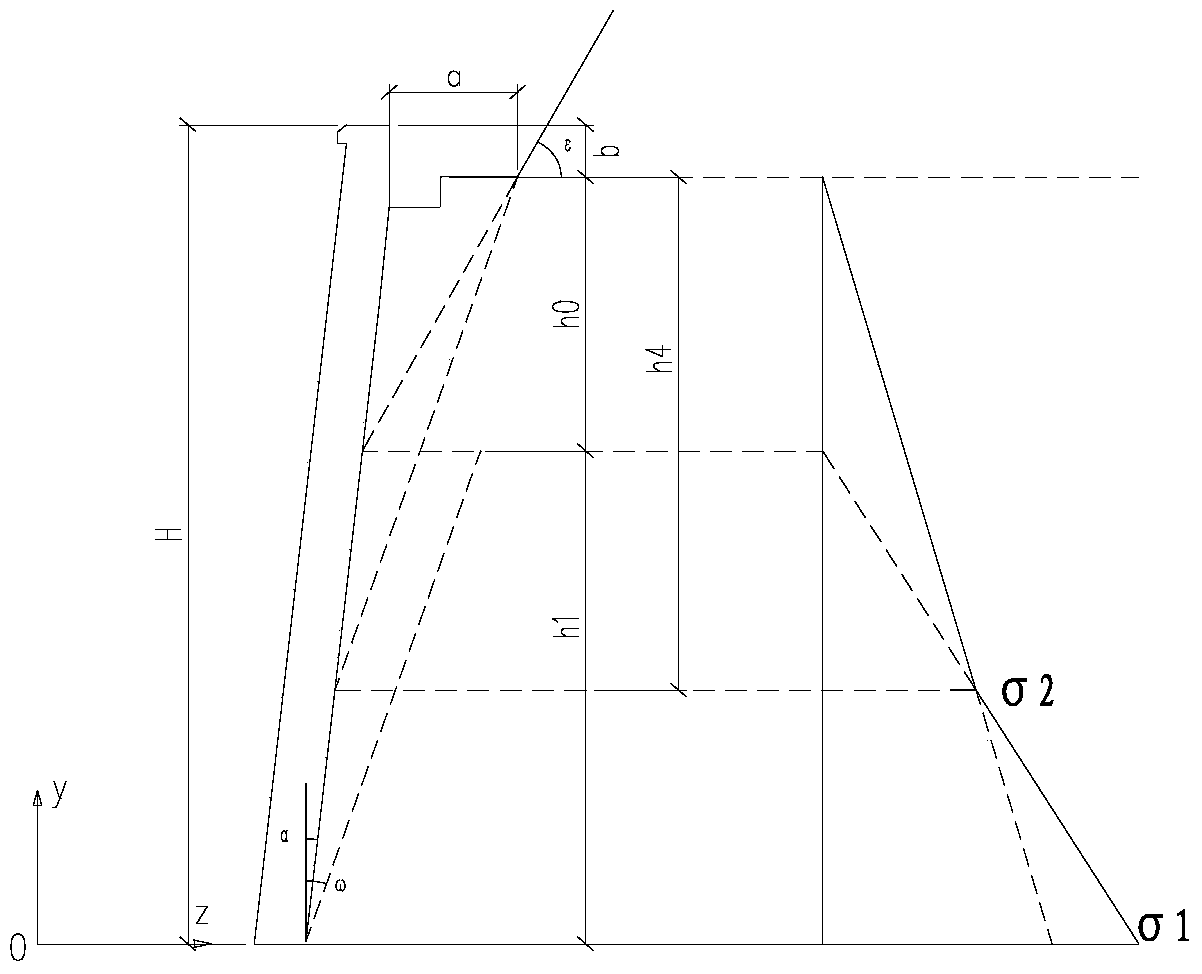

[0091] 1. Determine the basic calculation data, including formation characteristic parameters, building material parameters and stability parameters K 0 , while stratum characteristic parameters and building material parameters include side and uphill slope 1: m 3 Or uphill slope angle ε, surrounding rock level, stratum calculation friction angle Fracture angle ω, stratum weight γ, wall material weight γ d , friction coefficient f between the door and the lining 砼 , friction coefficient f between the door and the soil at the bottom of the wall 土 .

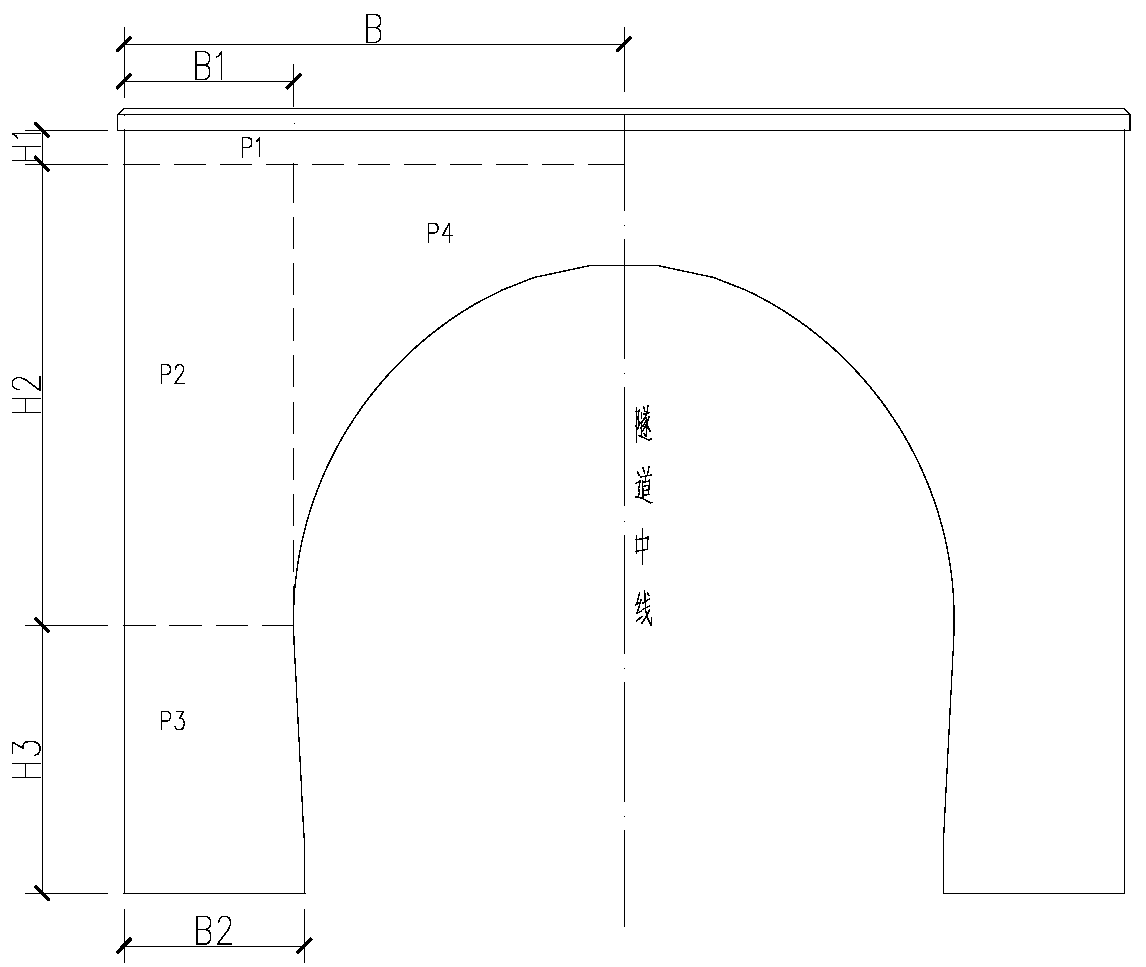

[0092] 2. Determine the size of each part of the door, refer to Figure 1 to Figure 2 , including slope rate 1: m 3 , the slope rate of the brea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com