Hanger with metal auxiliary seal and tubing equipment with hanger

A metal seal and hanger technology, which is applied in sealing/isolation, wellbore/well components, earthwork drilling and production, etc., can solve problems such as wellhead out of control, fluid surge, personnel injury, etc., achieve reliable sealing performance and improve sealing Performance, the effect of preventing seal failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

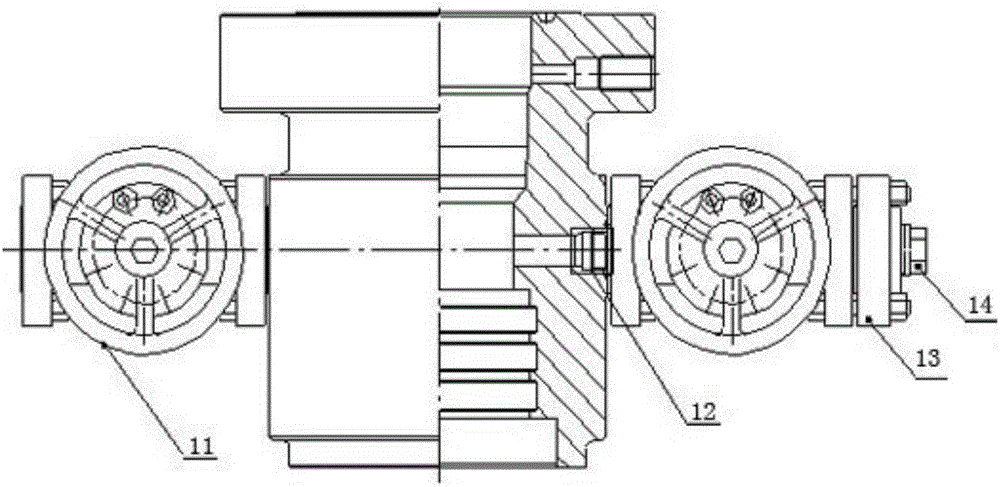

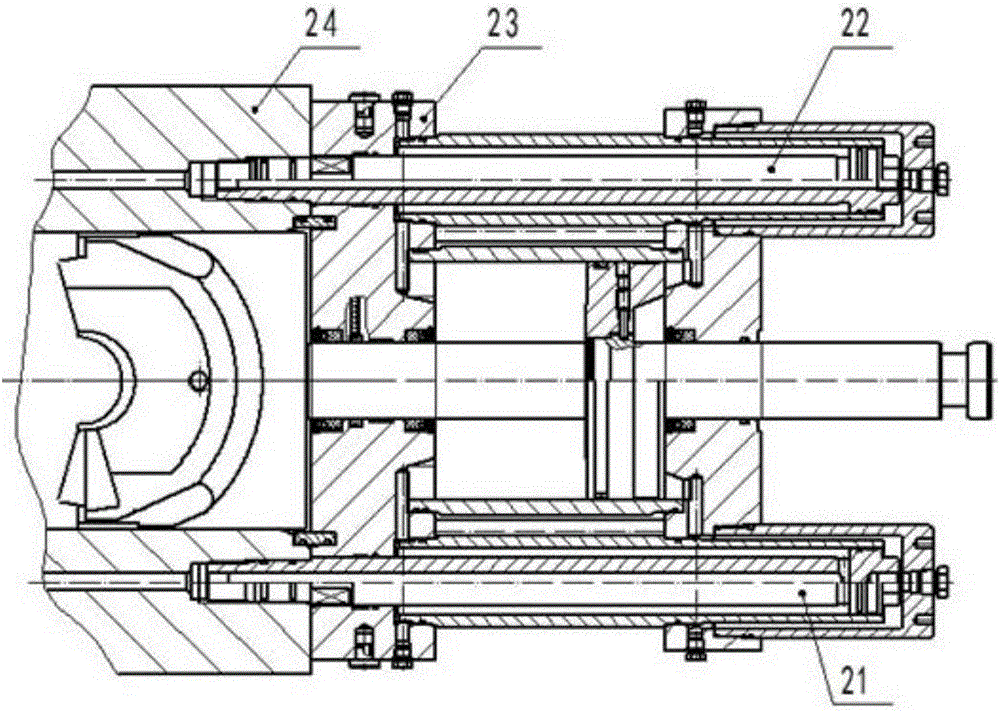

[0054] A hanger with a metal secondary seal, comprising a hanger body 42, a main seal assembly 48 using a metal seal is arranged between the shoulder of the hanger body 42 and the casing head 41 of the lower layer, the hanger A metal-sealed auxiliary seal assembly 44 is provided between the top of the body 42 and the upper casing head 45 , and a standard gasket ring 43 is provided between the upper casing head 45 and the lower casing head 41 .

Embodiment 2

[0056] On the basis of the first embodiment, an adjusting gasket is also provided between the secondary sealing assembly 44 and the upper casing head 45 .

Embodiment 3

[0058] On the basis of Embodiment 1, a pressure test hole 47 is opened on the outer cylindrical surface of the upper casing head 45, and the pressure test hole 47 is connected to the secondary sealing assembly through the pipeline inside the upper casing head 45. 44 and the bonding surface of the upper casing head 45 between the standard gasket ring 43.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com