Cage structure controls engine variable valves

A technology of engine valve and cage structure, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of poor precision, poor coordination, complex structure, etc., and achieve the effect of simple control, multi-directional control, and flexible angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

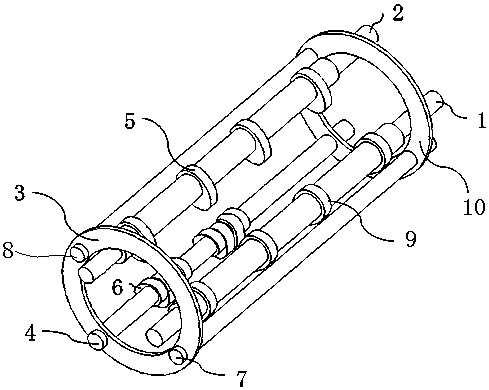

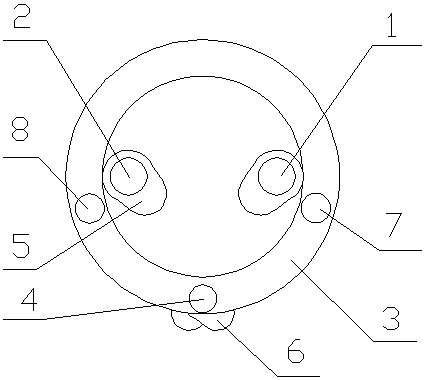

[0016] Attached below figure 1 and figure 2 The structural principle and working principle of the present invention are further described in detail.

[0017] see figure 1 , the cage structure controls the engine valve, including cage one 3 and cage two 10, cage one 3 and cage two 10 are fixed by transmission rod one 7 and transmission rod two 8, and are divided into transmission rod one 7 and transmission The two ends of bar two 8; Be provided with control shaft one 1 and control shaft two 2 in the ring inner side of cage ring one 3 and cage ring two 10; Execution shaft 4 two ends connect cage ring one 3 and cage ring two 10; Control shaft One 1 is provided with a cam one 9, the control shaft two 2 is provided with a cam two 5, and the execution shaft 4 is provided with a cam three 6.

[0018] The first transmission rod 7 and the second transmission rod 8 are horizontally installed between the first cage 3 and the second cage 10 .

[0019] The installation methods of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com