Double-convex-curved-surface contact sleeve steering structure of supporting column for tidal-current-energy generator set

A generator set and tidal current energy technology, which is applied in the direction of hydropower, engine components, machines/engines, etc., can solve the problems that the direction of the water turbine cannot be changed, and the generator set cannot use the tidal current to the greatest extent, so as to improve the service life and reduce the Abrasion, rotation and flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

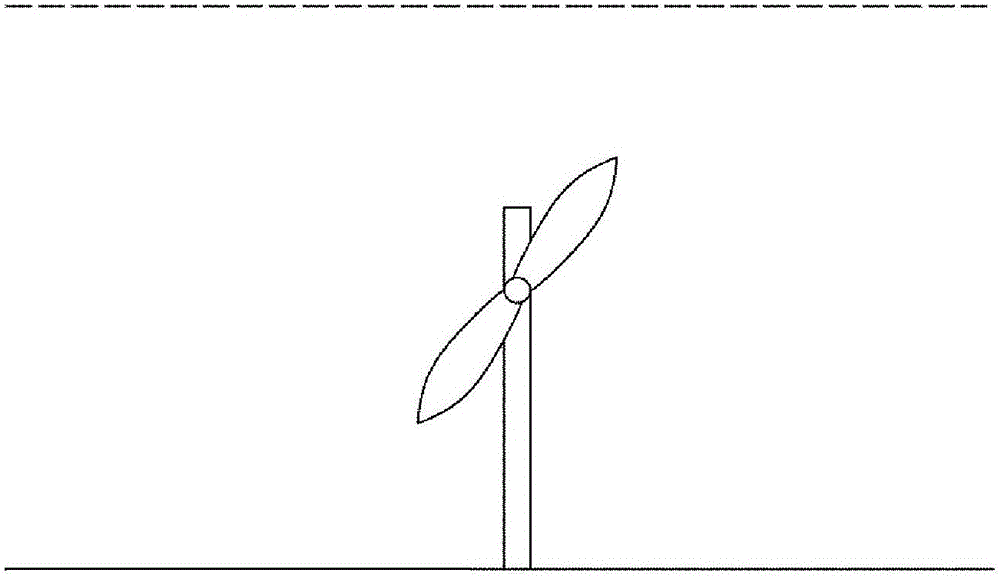

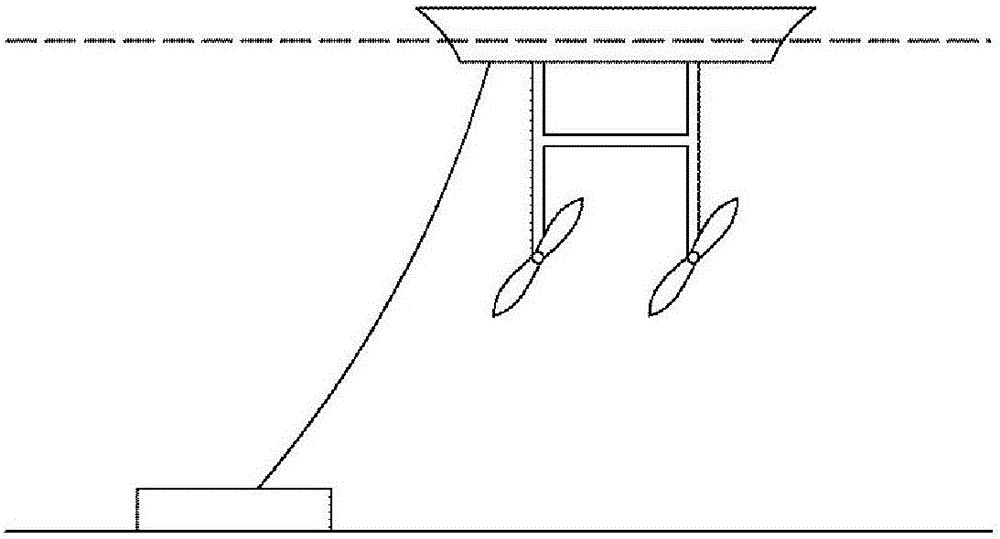

[0026] The double-convex surface contact sleeve steering structure of the tidal current energy generating set pillar, such as Figure 4 As shown, in the structure of the single-column double-spread tidal current energy generator set, the whole unit is a truss structure 2, the upper part of the unit has a working platform 1, and the upper part of the generator set 5 with blades 4 is installed with two cross-sections in the shape of an airfoil. 5. The pipeline stretches upwards at the beginning and spreads its wings 3; the unit base 8 is equipped with a pillar 9, and the top of the pillar 9 is in the shape of a curved surface 10; the main shaft 7 is fitted with a sleeve 11, and the sleeve 11 is equipped with a shaft sleeve 12; Cover 12 forms steering mechanism 6. The upper end of the main shaft 7 is connected to the lower part of the generator set 5, and the curved surface 17 of the lower end of the main shaft 7 is supported on the pillar 9 below, and the highest point 13 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com