Transmission speed change device

A technology of speed change device and shaft installation, applied in transmission device, friction transmission device, transmission control and other directions, can solve the problems of complex process, complex gear structure, high material requirements, and achieve high transmission efficiency, simple circuit, and shift time. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

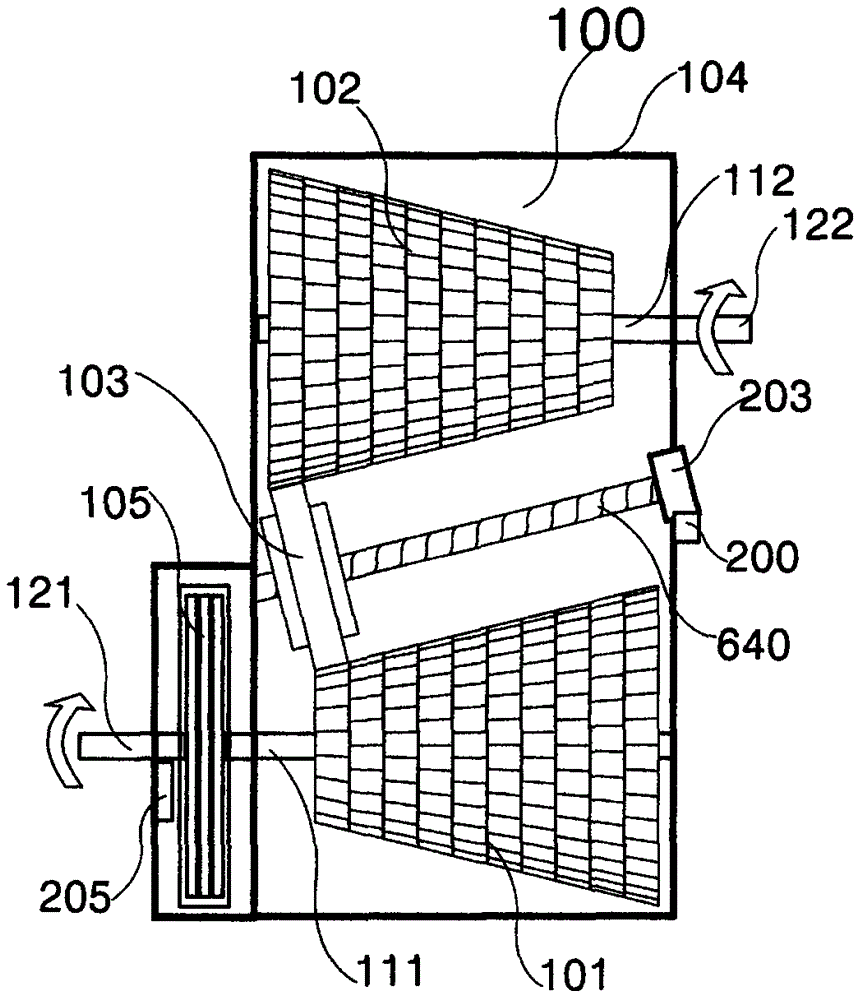

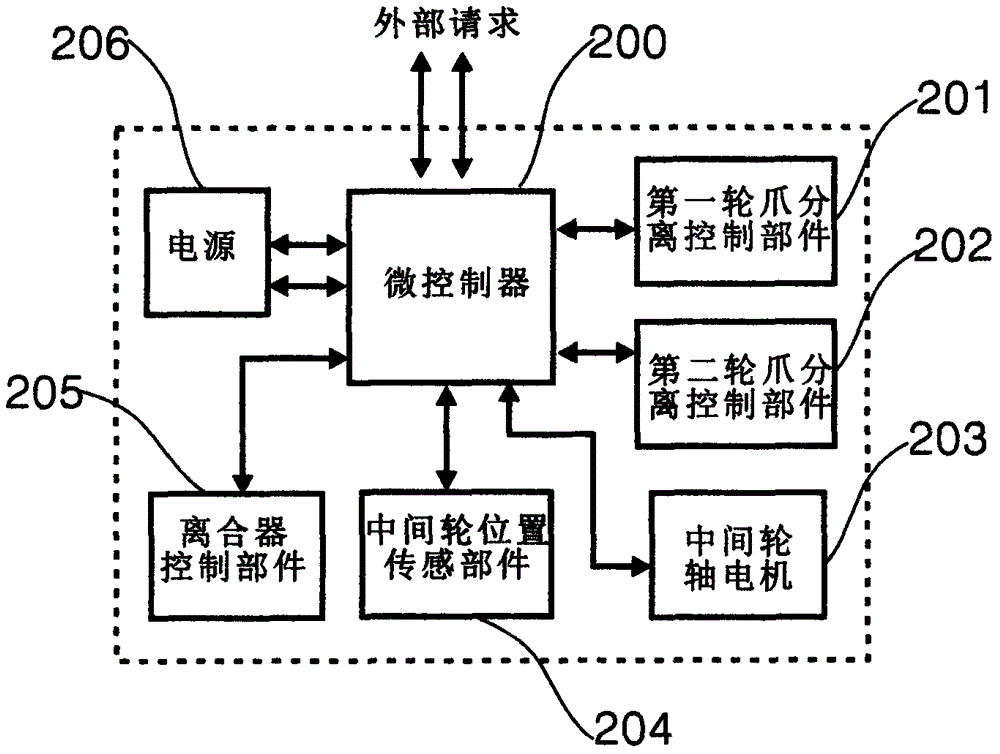

[0029] refer to figure 1 figure 2 , in the transmission transmission device (100) of the present invention, the input power is clockwise input at the front end of the clutch (105), and the clutch (105) is implemented by the clutch control part (205) under the control of the microcontroller (200). In the action of half-clutch and combined, the microcontroller (200) controls the clutch control part (205) to implement the combined action of the clutch (105) when the microcontroller (200) implements power output under an external request. The input cone shaft (111) drives the input cone (101) to rotate clockwise, the input cone (101) drives the intermediate wheel (103) to rotate counterclockwise, and the other end corresponding to the intermediate wheel (103) drives the output cone ( 102) Rotate clockwise to make the output cone shaft (112) rotate clockwise, realize power output at the end of the output cone shaft (112), and realize the transmission function of the transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com