Low-energy electromagnetic valve control method and device

A technology for control devices and solenoid valves, applied to valve devices, valve operation/release devices, valve details, etc., can solve problems such as increased power consumption, short life, easy-to-burn electromagnetic coils, etc., to achieve reduced temperature rise, Effects of extended life and reduced operating power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

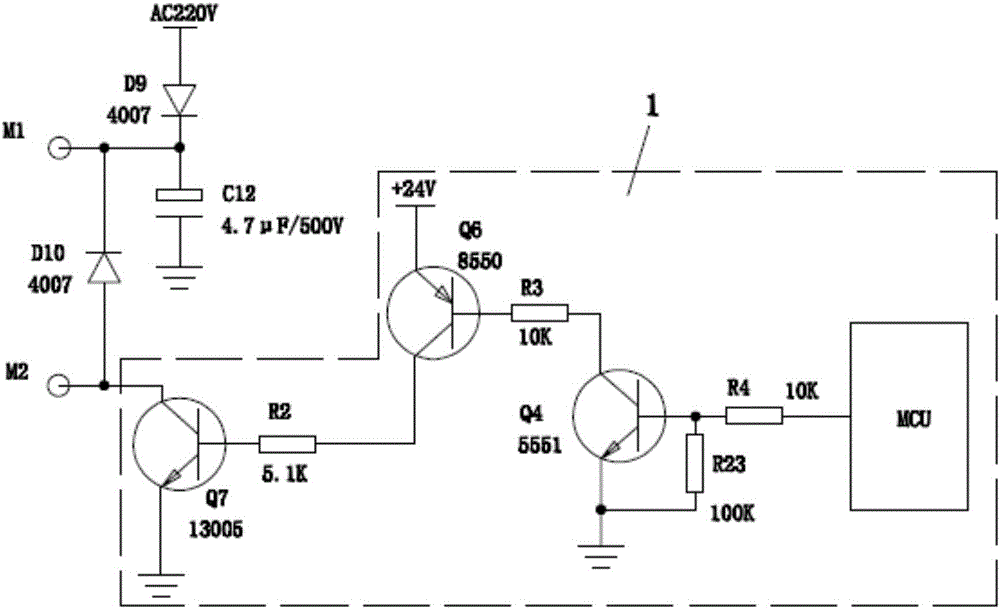

[0018] The specific embodiment of the present invention is as figure 1 As shown, a low energy consumption solenoid valve control device includes solenoid valve control output terminals M1 and M2 for controlling the solenoid valve. It also includes a composite drive circuit 1, the composite drive circuit 1 includes a control chip MCU, a resistor R4, a transistor Q4, a resistor R3, a transistor Q6, a resistor R2 and a transistor Q7 connected in sequence, the base of the transistor Q4 and its emitter are connected with a Resistor R23. The transistor Q7 is connected with the solenoid valve control output terminals M1 and M2. The control chip MCU can output a strong suction signal or a PWM pulse width modulation signal according to whether the solenoid valve is open or not. The strong suction signal can make the transistor Q7 drive the solenoid valve control output terminals M1 and M2 to output a current greater than or equal to the rated drive current value of the solenoid valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com