Phase change memory unit and forming method thereof

A phase-change storage and phase-change material technology, applied in the field of phase-change storage units and their formation, can solve the problems of increased power consumption of phase-change storage units, loss of heat from the upper electrode, etc., and achieves low cost, reduced voids, and guaranteed The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the above objects, features and advantages of the present invention more obvious and comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

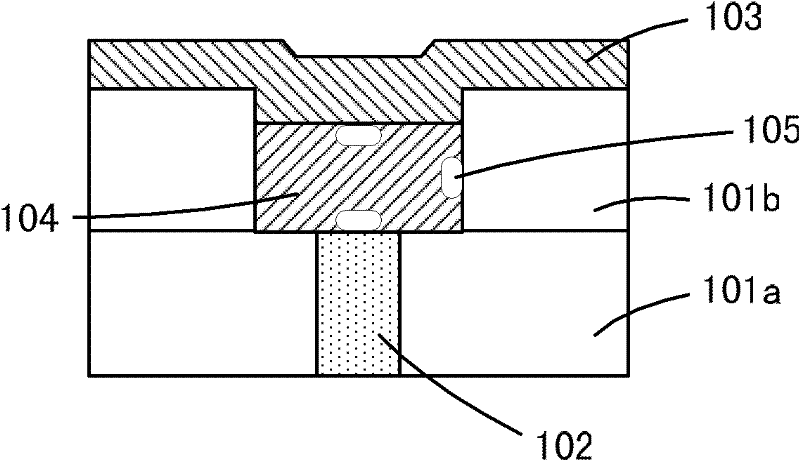

[0031] see figure 1 , the basic structure of the phase-change memory cell in the prior art is composed of a first isolation layer 101a, a second isolation layer 101b, a first electrode 102, a second electrode 103 and a phase-change material layer 104, wherein the phase-change material layer 104 is located at the second Between the first electrode 102 and the second electrode 103 , inside the insulating isolation layer 104 , is in contact with the heating resistor extending from the first electrode 102 . The severe heat generated by current injection can cause the phase change material to undergo a phase change. By controlling the injected current, voltage and operating time, the crystalline and amorphous states of the phas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com