Power amplifier control system and method based on automatic level control

An automatic level and control system technology, applied in electrical components, transducer circuits, sensors, etc., can solve the problems of wasting power amplifier performance, excessive power drop, unable to protect power amplifier in time, etc., to reduce working power consumption, The effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

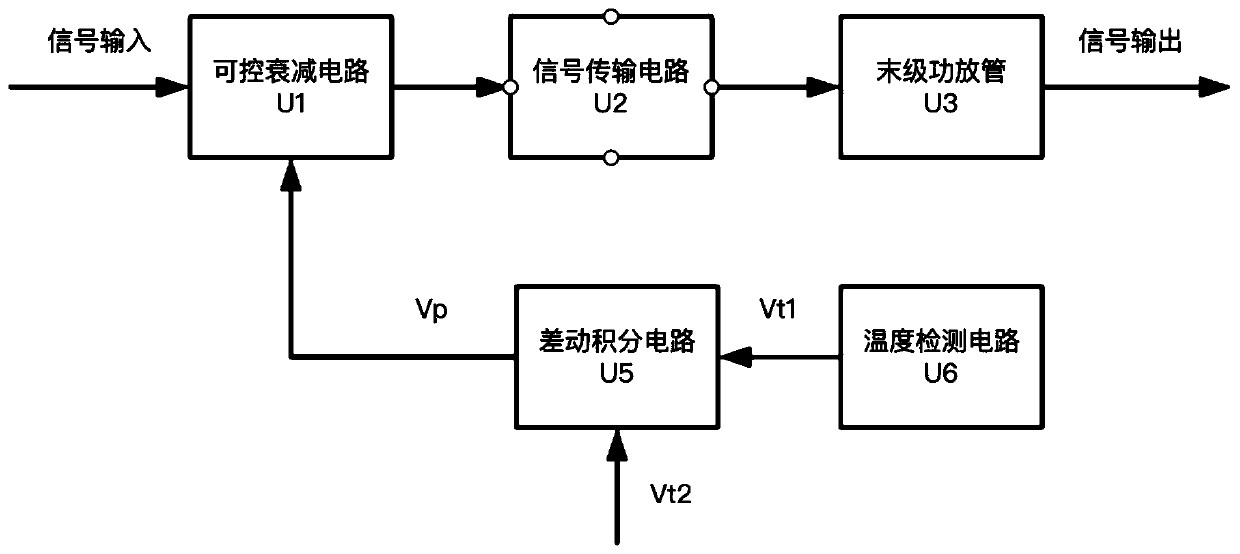

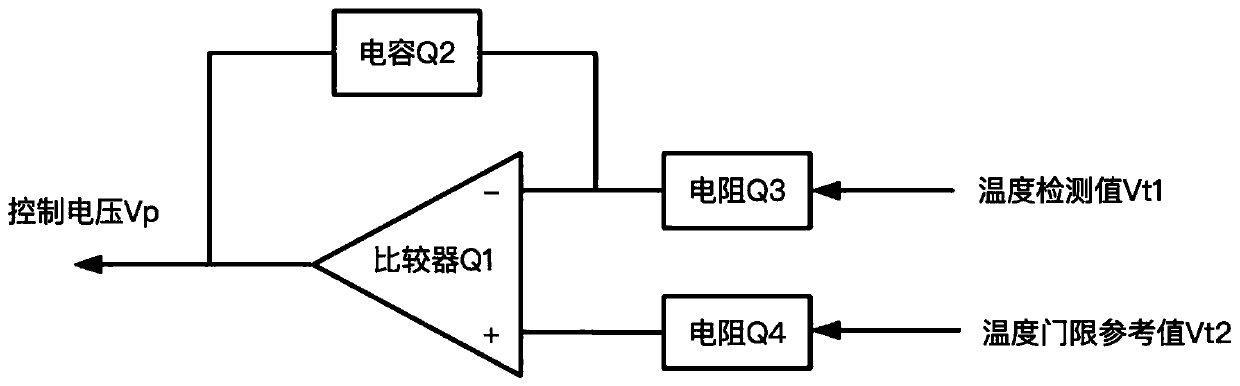

[0049] Embodiment 1: as attached figure 1 , 3 As shown, a power amplifier control system based on automatic level control includes a controllable attenuation circuit U1, a signal transmission circuit U2, a final power amplifier tube U3, a temperature detection circuit U6, and a differential integration circuit U5, wherein the controllable attenuation circuit U1 The first input terminal of the signal transmission circuit U2 is connected to the signal input, the second input terminal is connected to the output signal Vp of the differential integration circuit U5; the output terminal is connected to the signal transmission circuit U2; the input terminal of the signal transmission circuit U2 is connected to the controllable attenuation circuit U1, and the output terminal is connected to the terminal The first-stage power amplifier tube U3; the input end of the final-stage power amplifier tube U3 is connected to the output end of the signal transmission circuit U2, and the output e...

Embodiment 2

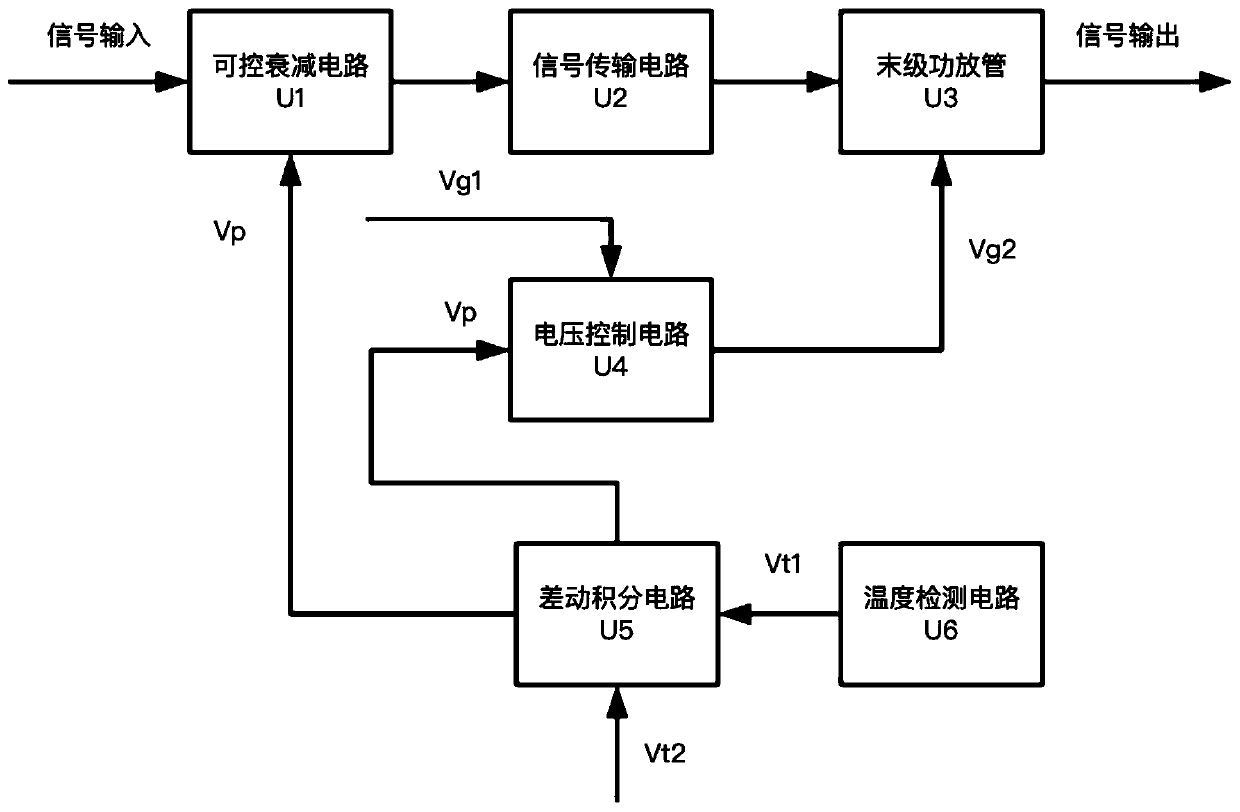

[0076] Embodiment 2: as figure 2 As shown, on the basis of Embodiment 1, a voltage control circuit U4 is also included. The first input port of the voltage control circuit U4 is connected to the standard voltage Vg1, and the second input port is connected to the output port of the differential integration circuit U5 to receive the control signal Vp; The output port of the voltage control circuit U4 is connected to the power input port of the final power amplifier tube U3; the power port of the final power amplifier tube is connected to the output signal Vg2 of the voltage control circuit U4.

[0077] In this embodiment, the voltage control circuit U4 has the interchangeability of digital circuits and analog circuits, such as Figure 4 As shown, the voltage control circuit in the form of a digital circuit includes ADC, DAC, single-chip microcomputer Q5 and two input signals Vp and Vg1; where Vp is the output control signal of the differential integration circuit; Vg1 is the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com