Horizontal-segment and elevating-segment integrated-type spiral conveyer

A technology of screw conveyor and horizontal section, which is applied in the field of integrated screw conveyor of horizontal section and lifting section, which can solve the problems of high cost, waste of power consumption, large occupied area, etc., achieves reduced occupied area, stable and reliable operation , The effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

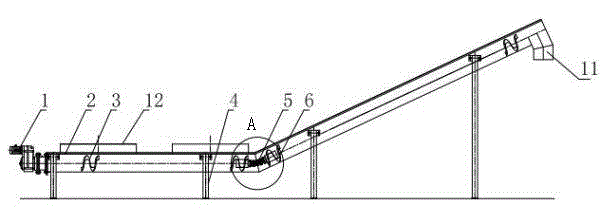

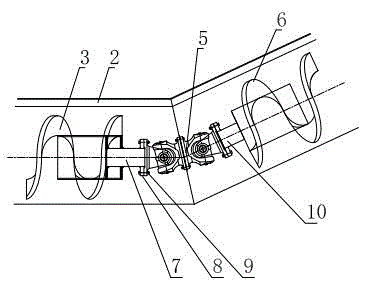

[0015] Such as figure 1 , figure 2 As shown, the screw conveyor of the present invention is divided into two parts, the horizontal section and the lifting section. The two-section conveying shells 2 are supported on the ground by brackets 4 with different heights, and are welded at the intersection to form an integral communication structure. The horizontal section The conveying pipe shell 2 is provided with a material receiving port 12 , and the upper end opening of the conveying pipe shell 2 of the lifting section is a discharge port 11 . In the center of the conveying tube shell 2 in the horizontal section, a horizontal part spiral blade 3 is arranged, and a horizontal shaft 7 is welded at both ends of the blade. At the starting end of the horizontal shaft 7, a power device 1 equipped with a motor and a reducer is set for driving; Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com