Structural health monitoring system of prefabricated assembly type concrete system, and integration method

A health monitoring system and prefabricated assembly technology, applied in the field of construction, can solve problems such as difficulty in ensuring accurate and timely extraction of force information of key structural components, damage to sensor installation structures, and harsh construction conditions, so as to improve configuration and use flexibility, Improving the survival rate of implantation and the effect of excellent construction environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

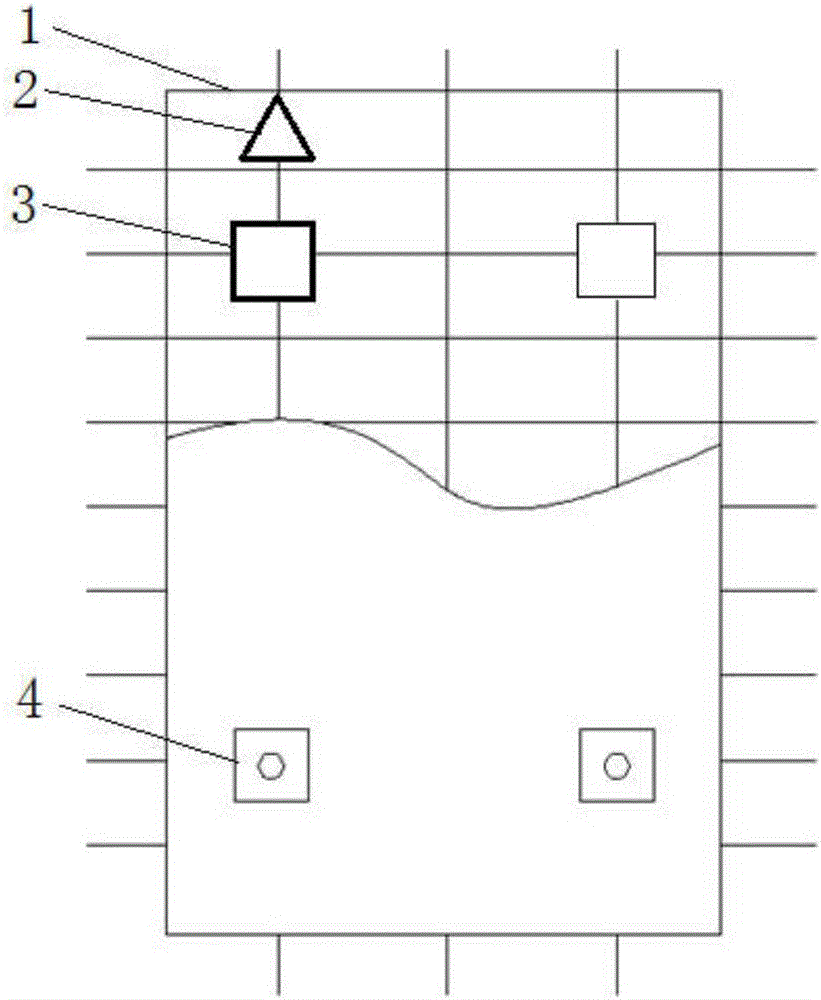

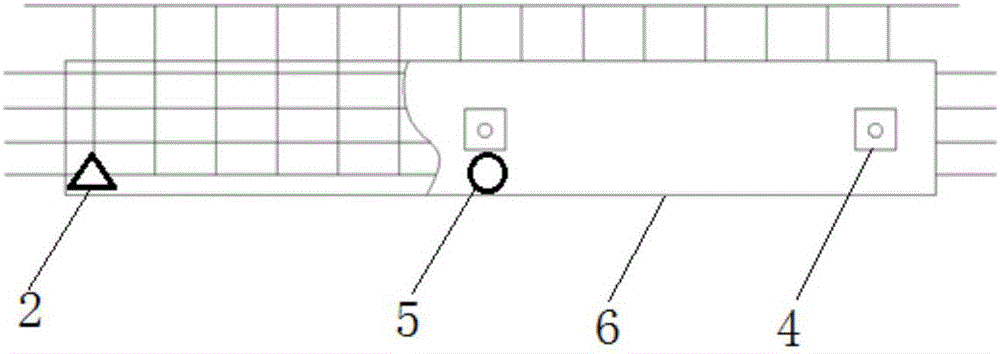

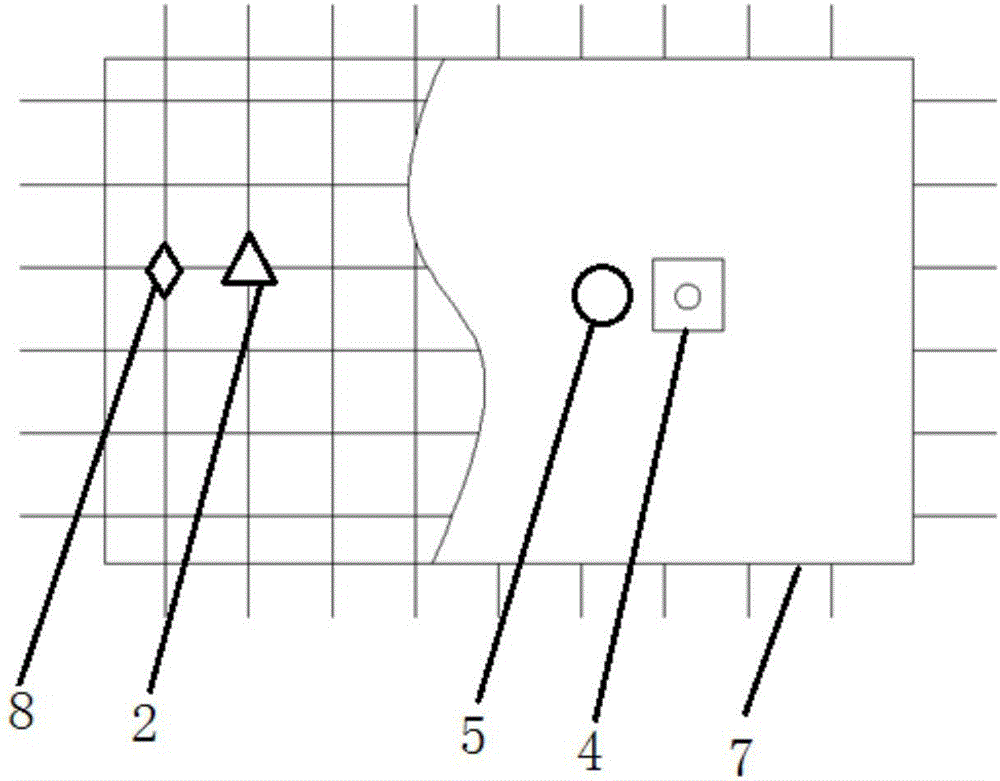

[0028] Embodiment 1: as Figure 1-Figure 5 As shown, the present invention is an integration method of a structural health monitoring system of a prefabricated concrete system. One or more sensors are implanted inside the prefabricated component, and the sensor communication interface is placed in the prefabricated concrete component. On the surface, after the on-site assembly of each component is completed, during the decoration construction process, each sensor is connected to the monitoring system analysis terminal through the sensor communication interface of the component, so that various structural information of the component can be transmitted to the monitoring system terminal through the above sensors.

[0029] The structural health monitoring system of the prefabricated assembled concrete system of the present invention presets one or more sensors in the prefabricated assembled concrete member, and the sensor communication interface is placed on the surface of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com