Multifunctional monitoring device for corrosion damage of underground concrete structure

A concrete structure and damage monitoring technology, which is applied in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems of easy to be affected by moisture, poor durability, real-time and automatic monitoring difficulties, etc., to reduce volume, reduce impact, Effects that are easy to observe in real time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

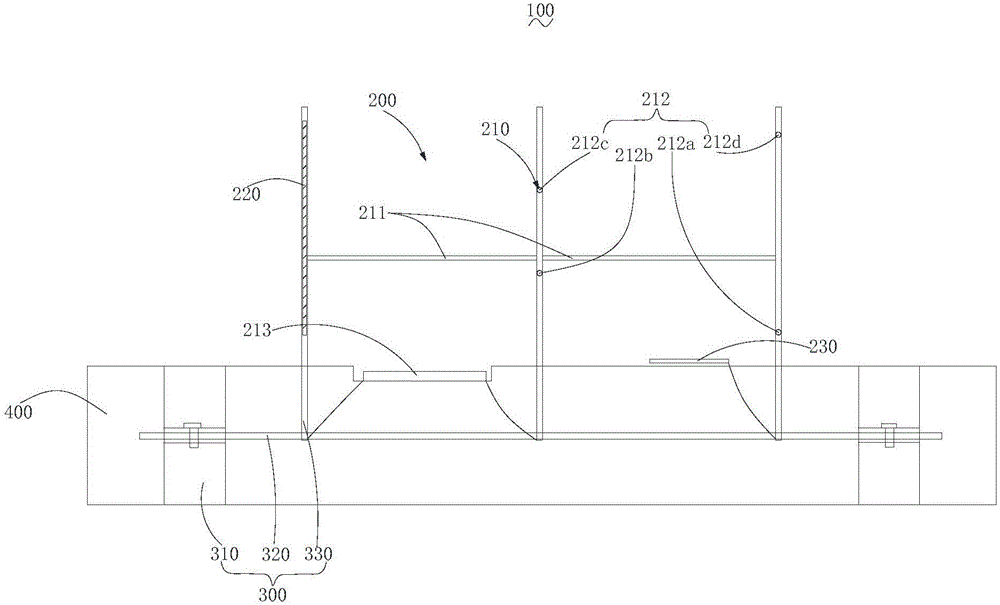

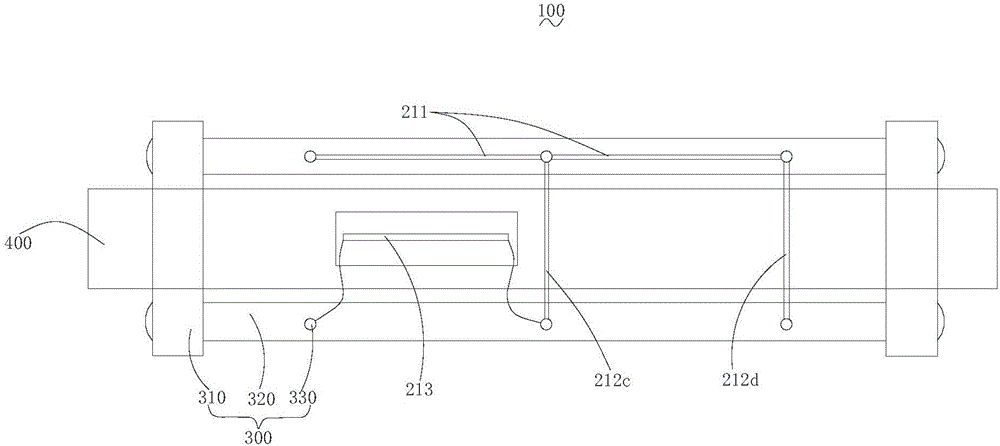

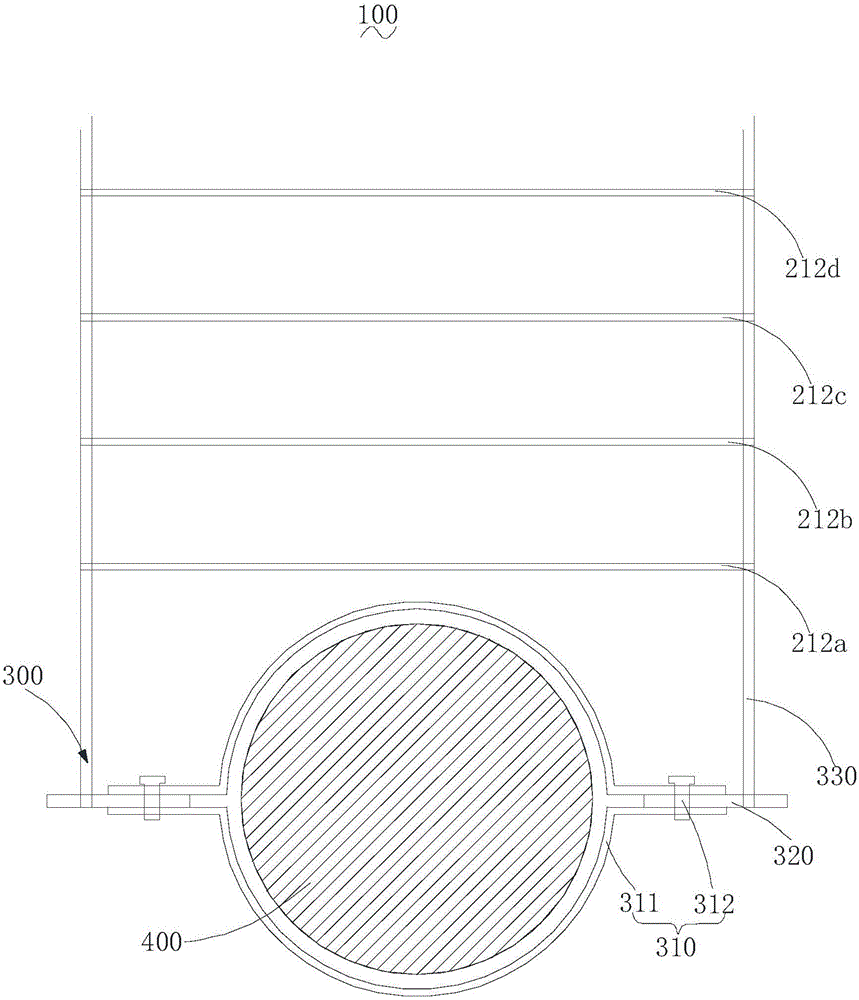

[0031] Please refer to figure 1 , this embodiment provides a multifunctional underground concrete structure corrosion damage monitoring device 100, which is suitable for connecting with the steel bar 400 of the underground concrete structure. The multifunctional underground concrete structure corrosion damage monitoring device 100 includes a monitoring system 200 and a fixing mechanism 300. The monitoring system 200 is installed on the steel bar 400 through the fixing mechanism 300, and the monitoring system 200 can monitor the corrosion damage of the underground concrete structure in real time and automatically.

[0032] The monitoring system 200 includes a temperature sensor 220, a pH value monitoring device 230, a strain sensor 210 and a wireless transmission device (not shown).

[0033] The wireless transmission device is used to connect with the temperature sensor 220, the pH value monitoring equipment 230 and the strain sensor 210, and transmit the signals collected by t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com