Combined machine tool for boring rocker arm holes

A combined machine tool and boring bar technology, used in boring/drilling, drilling/drilling equipment, metal processing equipment, etc., can solve problems such as fading accuracy, difficult to guarantee processing quality, and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

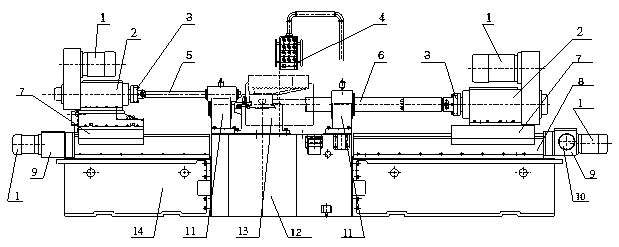

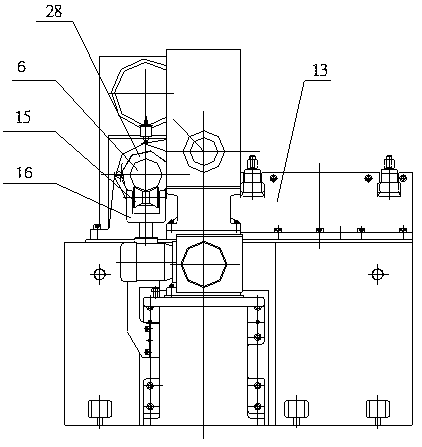

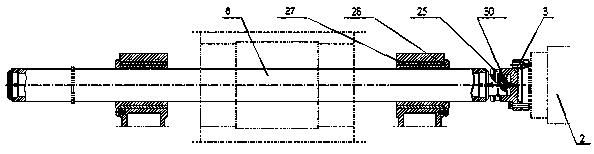

[0031] like figure 1 As shown, the boring "rocker arm" hole combination machine tool, the general layout of the machine tool is a horizontal double-sided machining layout, the middle base 12 is the main body, and is the most important connecting piece, and two boring frames 11 are installed at both ends of the top surface. , the large boring bar 6 passes through the two boring frames 11 to form the most rigid "double support" frame, one of the boring frames 11 has a small boring bar 5 side by side to drill the hole of the boring bar, although it is supported on one side, it also adopts "Double support" structure. On the rear part of the top surface of the base 12, a removable fixture 13 is installed to adapt to the processing of parts of different specifications. In addition, if the clamping rigidity is found to be insufficient during rough machining, a vibration-damping screw or jack can be added to the front end of the workpiece.

[0032] On both sides of the base 12 are t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com